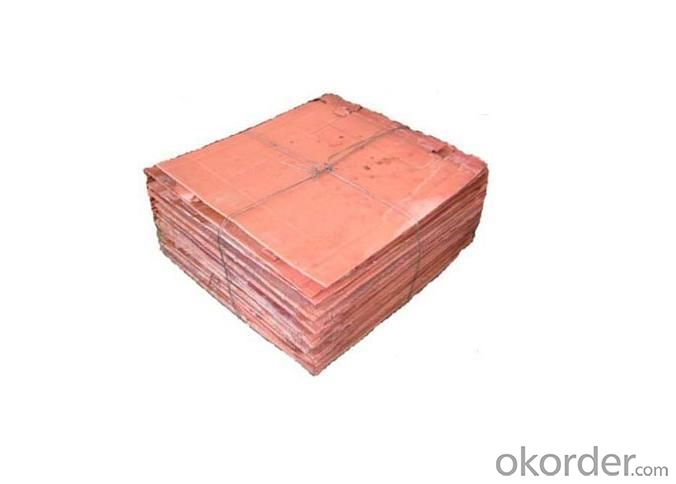

Electrolytic Copper with Factory Outlet Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Kilograms kg

- Supply Capability:

- 50000000 Kilograms per Year kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

purity: 99.7%min

particle size:-250 Mesh

loose density:<=1.76g/cm3

factory outlet price...

1,High-conductivity oxygen-free copper

2,For wire and cable

3,Thickness :0.1-0 .8 mm

4,Width :20-420mm Copperbelt Specification

TU1 TU2(T2) C10200 C1020

Quality standard Depth 0.1mm-0.8mm

Width ≤420mm

Length ≤5000m

Side camber ≤150mm/n

Hardness 55HV-100HV

Eiectic conductivity ≥100%

Tensile Strenhth ≥195MPA

Eiongation ≥40%

Resistance ≤0.01724

Oxygen Content ≤0.0008%

Cu.Purity ≥99.97%

- Q: What is the raw material used in the production of plastic products?

- The microwave oven lunch box is made of this kind of material. It is resistant to high temperature at 130 degrees and has poor transparency. It is the only plastic box which can be put into the microwave oven. It can be reused after careful cleaning. Particular attention should be paid to the fact that some microwave oven boxes are made of size 05, but the box cover is made of size 06 PS (polystyrene). PS has good transparency and is not high temperature resistant, so it can not be put into the microwave oven with the box body together. PP. For insurance purposes, put the container in front of the microwave oven and remove the lid first.

- Q: The difference between resin and plastics

- Resin material: it is natural, extracted from plants, the cost is higher. Plastic: it is chemical material, extracted from petroleum, Chen is lower

- Q: Raw materials for making plastic bags

- Polyethylene (Polyethylene, PE), referred to as PE. It is a high molecular organic compound which is made up of ethylene. Polyethylene is recognized as the best food for contact with food in the world. Non-toxic, tasteless, odorless, in line with food packaging hygiene standards. Polyethylene film, light and transparent, with moisture-proof, anti - oxygen, acid, alkali, air tightness, heat sealing and other outstanding performance. Known as "plastic flower" laudatory title. It is the most important and most important material in plastic packaging and printing.

- Q: What is the material of plastic dip?

- Also known as alias dip coated, hot dip coating, hot compress. Dip (plastic) is a kind of plastic coating process. According to the different raw materials used in dipping, they can be divided into liquid dipping (coating) and powder dipping (coating).

- Q: What are the materials for making plastic buckets? How many are there?

- Any theory can be made of plastic barrel type container, but for performance and cost considerations, the vast majority of plastic barrels are polyethylene or polypropylene products, drinking machine bucket is the use of polycarbonate (PC). The specific use of what material, to see what you plan to install.

- Q: How to identify the proportion of nozzle material in plastic?

- The melt index is detected by a melt flow rate analyzer. If the nozzle is added, the melt index will generally increase

- Q: PVC what chemicals do you need for plastic surface treatment?

- Different processing methods are often required for different materials.

- Q: What are the materials for making plastic basins? Are they raw materials?

- Generally PP material, transparent is raw material, opaque is not necessarily

- Q: What are the raw materials made of modified plastics?

- Plastic modification is to petrochemical production out of large quantities of general resin through physical, chemical, mechanical, improve or increase their capabilities to special environmental conditions in electricity and magnetism, light, heat, aging resistance, flame retardancy, mechanical properties and other aspects of the use function. Modified plastics is a plastic industry involving a wide range of areas, high technology content, and the modification technology of plastics - filling, blending and modification is raw materials and processing plastic products into almost all of the. From the production of raw material resin to the modification of plastic masterbatch from various specifications and varieties, in order to reduce the cost of plastic products and improve their functionality, the plastic modification technology can not be separated

- Q: What are the bulk density, size and moisture content of the general plastic material?

- Among them, the mass of the material has nothing to do with the particle size, but the larger particles have larger volume due to the presence of more voids between the particles. Small particles (powder) to the general packing is very tight, so the smaller bulk density.

1. Manufacturer Overview

| Location | Shandong,China (Mainland) |

| Year Established | 2008 |

| Annual Output Value | Above US$100 Million |

| Main Markets | 40.00% Africa 20.00% South America 10.00% Southeast Asia 10.00% Mid East 10.00% North America 10.00% Eastern Asia |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | percent of export |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | average |

Send your message to us

Electrolytic Copper with Factory Outlet Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Kilograms kg

- Supply Capability:

- 50000000 Kilograms per Year kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords