Irradiation Cross-linkable Low Smoke Zero Halogen Flame Retardant Polyolefin Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

cross link compound:

(1) competitive price

(2) 30 years of experience

(3) stable quality

(4) customized product

Cross Link Compound:

1. Applications and cable specifications:

Used for 125°C less than 3KV locomotive cable, meeting GB/T 12528-2008. Suitable for environment with pollution of mineral oil and fuel oil.

2. Description:

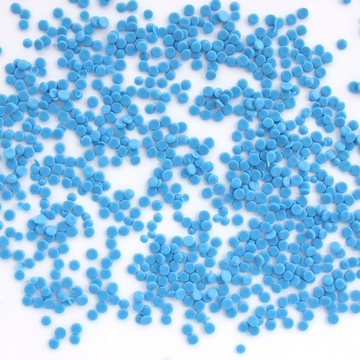

Irradiation low smoke halogen free flame retardant POE compound for locomotive cable, based on special high oil resistant POE resin, is produced and pelletized by special technology, adding special modifier, halogen-free flame retardant, anti-oxidant, assistant crosslinker and other special additives.

3. Processing:

The compound can be processed with conventional extruders, and the normal PVC screw with a minimum 20:1 L/D. It is better if use low compression ratio screw.

The following temperature(°C) profile of extruder is recommended:

| Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

| temperature °C | 130 | 145 | 150 | 150 | 145 | 145 |

4. Storage and transport:

Packing: 25kg/bag, PE membrane inside bag and craft outside bag.

Avoiding in direct sunlight and weathering.

Storage place should be clean, cool, dry and ventilated.

5. Irradiated dosage:

The normal irradiated dosage(recommended) of irradiation cross-linkable low smoke halogen free flame retardant POE compound is 13 megarad.

6. Properties:

| Item | Unit | JFDW6125-G01 | JFDW1125-J01 | JDW1150-J02 | FDW6125-A01 | ||||

| Standard | Typical | Standard | Typical | Standard | Typical | Standard | Typical | ||

| Density | 1.44 | 1.43 | 1.34 | 1.45 | |||||

| Hardness | Shore A | 91 | 98 | 98 | 97 | ||||

| Tensile Strength | ≥Mpa | 9 | 13.7 | 10 | 15.8 | 30 | 32.6 | 17.8 | |

| Elongation at Break | ≥% | 125 | 191 | 125 | 273 | 100 | 230 | 170 | |

| Thermal Aging | Condition °C×h | 158×168 | 158×168 | 178×168 | 158×168 | ||||

| Variation on tensile strength | ≤ % | -25 | -6 | -25 | -12 | Not break | Not break | -25 | -8 |

| Elongation at Break | ≥% | 100 | 174 | 100 | 231 | 100 | 162 | ||

| Variation on Elongation | ≤ % | -40 | -9 | -40 | -15 | -40 | -5 | ||

| Thermal Prolongation: 20N/cm2 | °C×min | 200×15 | 200×15 | 200×15 | |||||

| Elongation Under Load | ≤ % | 100 | 20 | 100 | 75 | 100 | 15 | ||

| Permanent Deformation | ≤ % | 25 | 0 | 25 | 0 | 25 | 0 | ||

| Ozone Resistance | |||||||||

| Ozone density and time, Method A | ppm×h | 250-300×24×25 | 250-300×24×25 | 250-300×3 | 250-300×24×25 | ||||

| Ozone density and time, Method B | ppnm×h | 200±50×72×40 | 200±50×72×40 | 200±50×72×40 | |||||

| Surface after test | Non cracking | pass | Non cracking | pass | No fissure and not break | Non cracking | pass | ||

| Oil resistance | Oil | 20# machine oil | 20# machine oil | 902# machine oil | |||||

| Condition °C×h | 100×70 | 120×70 | 100×70 | ||||||

| Variation on Tensile Strength | ≤ % | -50 | -22 | Variation of outer diameter ≤ ±5 | ±30 | -16 | |||

| Variation on Elongation | ≤ % | -50 | -35 | Not break | ±40 | -11 | |||

| Oil resistance | Oil | 0# diesel | 0# diesel | 903# diesel | |||||

| condition °C×h | 70×168 | 70×168 | 70×168 | ||||||

| Variation on Tensile Strength | ≤ % | -55 | -38 | Variation of outer diameter ≤ ±5 | ±30 | -18 | |||

| Variation on Elongation | ≤ % | -55 | -47 | Not break | ±40 | -26 | |||

| Impact Brittleness Temperature | ≤°C | -40 | pass | -40 | pass | -60 winding | pass | -40 | pass |

| Volume Resistivity at 20 °C | ≥Ω.m | 1.0×1012 | 4.8×1012 | 1.0×1012 | 2.0×1013 | 1.0×1012 | 2.0×1013 | ||

| Dielectric Strength | ≥MV/m | 20 | 27 | 20 | 27 | ||||

| 150°C high temperature stress | ≤ % | 50 | 13 | ||||||

| friction resistance (round trip) | ≥ times | 1000 | pass | ||||||

| Oxygen Index | ≥ | 30 | 33 | 30 | 34 | 30 | 34 | ||

| Smoke density Flaming | ≤ | 100 | 67 | 100 | 83 | 100 | 67 | 100 | 65 |

| Non Flaming | ≤ | 200 | 164 | 200 | 185 | 200 | 164 | 200 | 196 |

| Acidity of gases evolved (PH value) | ≥ | 4.3 | 5.1 | 4.3 | 5.0 | 4.3 | 5.1 | 4.3 | 5.0 |

| Conductivity of gases evolved | ≤μs/mm | 10 | 2.0 | 10 | 2 | 10 | 2 | 10 | 2 |

| Toxicity Index | ≤ | 5 | 2 | 5 | 2 | ||||

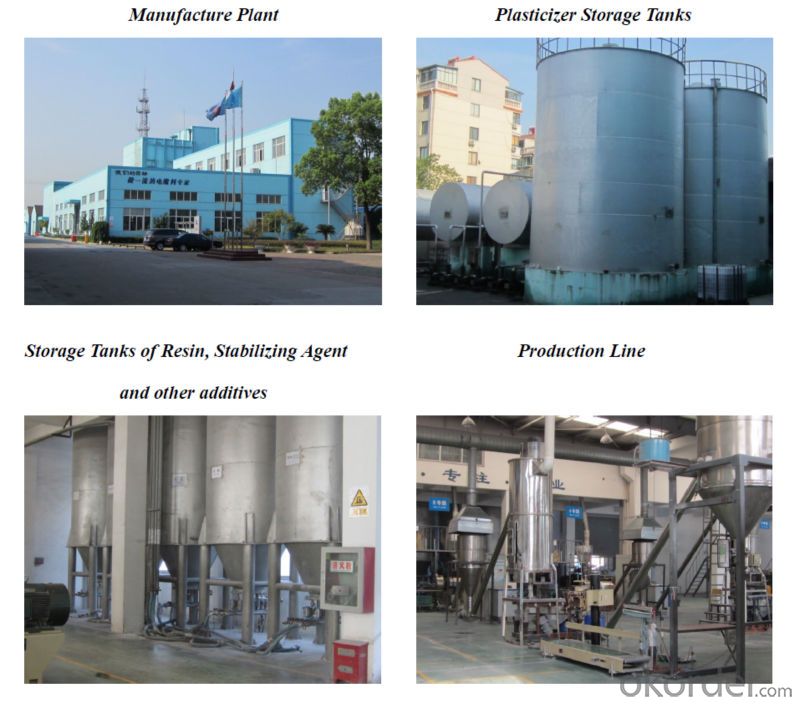

7. Company

- Q: What are the common raw materials used in plastic bottles? What are the main features?

- PE bottles and PP bottles are similar, toughness is better than PP, but rigidity and heat resistance are poor, solvent resistance is good, plastic soy sauce bottles seem to be PE, temporary loading a small amount of wine, kerosene will do.

- Q: How many kinds of plastic do you have?

- B. foam:Foam plastics can be divided into three kinds of hard, semi hard and soft foam. Hard foam without flexibility, compression hardness is very big, only up to a certain stress deformation, stress the lifting of restitution; soft foam rich flexibility, compression hardness is very small, very easy to deformation, stress release after can restore the residual deformation small; semi rigid foam between flexibility and other properties between hard and soft foam.

- Q: What is the concept of plastic raw materials for turnover containers?

- Plastic turnover box, other features: 1) plastic turnover box outer dimension refers to the maximum size of the logistics box cover. 2) the plastic turnover box has no standard inner concave, and the case size is 18mm. 3) the carrying capacity of a plastic turnover box means that the load is uniformly placed within the range of the environmental temperature. 4) the effective working temperature of the plastic turnover box is -25 DEG C - 40 DEG C. 5) plastic turnover boxes can be stacked for storage, saving space.

- Q: What are the raw materials for making plastics?

- Plastic raw materials are extracted from some oil in the part of PC is most familiar with the material extracted from the oil, the PC material has a gasoline burning time; ABS is made from coal, ABS will show when soot like burn out; POM extraction from natural gas, POM will have a very smelly smell of gas when burned.

- Q: Is the tableware made of PP raw material the best of those plastic tableware?

- Plastic tableware with melamine resin powder heat pressing, also known as melamine tableware melamine tableware.PP plastic is polypropylene, non-toxic, can make pots, buckets and other kitchen utensils.

- Q: PE plastic bellows raw material formula (PE and PP ratio, as well as other filling)?

- The additives are mostly organic additives, and they are usually analyzed by infrared, nuclear magnetic resonance and mass spectrometry. Fillers are mostly calcium carbonate, kaolin and other fillers, play a role in strengthening and reducing costs, and can be qualitatively and quantitatively analyzed by thermogravimetric analysis and fluorescence spectroscopy. After sample pretreatment, a single component, for unknown components need to go through a variety of instruments integrated spectrum, the final reduction formula, get the whole component analysis report.

- Q: What are the raw materials of plastics made of?

- Some plastics are pure resins, such as polyethylene, polystyrene and so on. They are called single component plastics. Some plastics, in addition to synthetic resins, also contain other auxiliary materials, such as plasticizers, stabilizers, colorants, various fillers, etc., known as "multi component plastic.".

- Q: What are the raw materials for environmental friendly portable plastic bags?

- [environmental protection plastic bags], including recycled materials, plastic bags and new materials, plastic bags. In the process of producing plastic bags, degradable plastic bags are added to degradable plastic bags, and degradable plastic bags can be automatically decomposed after 90 days in certain conditions.

- Q: What does MFI mean in PC material?

- MFI- melt flow index, also known as the melt flow rate (MFR), it was determined at a given shear stress (with applied load) and temperature, melt flow properties of materials (measured by g/10min).

- Q: Aluminum Alloy door corner with what plastic raw materials do?

- If the diagonal code requirements are not high, you can arbitrarily first a PP material.

Send your message to us

Irradiation Cross-linkable Low Smoke Zero Halogen Flame Retardant Polyolefin Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches