Organic Insulation Materials

Organic Insulation Materials Related Searches

Natural Insulation Materials Marine Insulation Material Roof Insulation Materials Recycled Insulation Open Cell Insulation Organic Solar Cells Indoor Insulation Home Insulation Nasa Insulation Material Cellulose Insulation Boiler Insulation Material Insulation Wool High Thermal Insulation Insulation Materials For Lunch Bags Insulation Services Organic Printed Solar Cells Indoor Window Insulation Foil Roof Insulation Materials Silica Insulation Exterior Polystyrene Insulation Organic Polymer Solar Cells Cavity Insulation Insulation Plate Printed Organic Solar Cells Ceramic Sheet Insulation Faced Insulation Indoor Window Insulator Packaging Materials Loft Insulation Commercial Roofing MaterialsOrganic Insulation Materials Supplier & Manufacturer from China

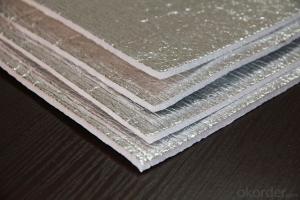

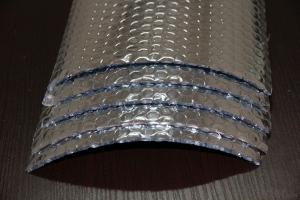

Organic Insulation Materials are a group of eco-friendly materials that are designed to provide thermal insulation in various applications. These materials are derived from renewable resources and are known for their sustainability and minimal environmental impact. They are widely used in construction, automotive, and industrial sectors to enhance energy efficiency and reduce heat loss, making them an essential component in modern green building practices. As a result, the demand for Organic Insulation Materials is steadily growing, with many industries recognizing their benefits in terms of both performance and environmental responsibility. Okorder.com is a leading wholesale supplier of Organic Insulation Materials, offering a vast inventory to cater to the diverse needs of customers across different industries. With a strong commitment to quality and customer satisfaction, Okorder.com ensures that the Organic Insulation Materials they provide meet the highest standards of performance and sustainability.Hot Products