Low Smoke Halogen Free Flame Retardant Polyolefin Insulating Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Polyolefin:

1. competitive price

2. 30 years of experience

3. stable quality

4. customized product

Polyolefin:

1. Applications and cable specifications of Polyolefin:

Common insulation for flame retardant wires and cables.

2. Description of Polyolefin:

Thermoplastic, low-smoke, halogen-free and flame retardant POE insulating compound, based on POE resin, is produced and pelletized by special technology with adding special modifier, flame retardant, anti-oxidant and other special additives.

3. Processing of Polyolefin:

The compound can be processed with conventional extruders, and the screw with a minimum 20:1 L/D and a compression ratio of 1.2 is recommended.

The following temperature(°C) profile of extruder is recommended:

| Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

| temperature degree C | 140 | 145 | 150 | 150 | 145 | 145 |

Note:Compound should be dried at 70-80°Cbefore use, which has storage time exceeding two months.

4. Storage and transport of Polyolefin:

Packing: 25kg/bag, PE membrane inside bag and craft outside bag

Avoiding in direct sunlight and weathering

Storage place should be in clean, cool, dry and ventilated conditions

5. Properties of Polyolefin:

| Item | Unit | DW9003 | DW9003A | DW9003B | DW9003C | ||||

| Standard | Typical | Standard | Typical | Standard | Typical | Standard | Typical | ||

| Density | g/cm3 | -- | 1.46 | -- | 1.45 | -- | 1.43 | -- | 1.49 |

| Hardness | Shore A | -- | 95 | -- | 94 | -- | 93 | -- | 97 |

| Tensile Strength | ≥MPa | 9 | 12.5 | 9 | 12 | 9 | 13 | 9 | 12.5 |

| Elongation at Break | ≥ % | 125 | 210 | 125 | 160 | 125 | 200 | 125 | 180 |

| Thermal Aging | degree C×h | 110×240 | 110×240 | 110×240 | 110×240 | ||||

| TS/EB Retention | ≥ % | 75/75 | 110/83 | 75/75 | 108/87 | 75/75 | 112/89 | 75/75 | 112/85 |

| Hot Deformation 80 degree C 4(6)h | ≤ % | 50 | 24 | 50 | 25 | 50 | 21 | 50 | 19 |

| Impact Brittleness Temperature | ≤ degree C | -20 | Pass | -20 | Pass | -20 | Pass | -20 | Pass |

| Volume Resistivity, at 20 degree C | ≥Ω*m | 1.0×1012 | 2.1×1012 | 1.0×1012 | 2.0×1012 | 3.0×1012 | 6.0×1012 | 1.0×1012 | 3.8×1012 |

| Oxygen Index | ≥ | 30 | 35 | 28 | 29 | 28 | 30 | 35 | 37 |

| Smoke Density Flaming | ≤ | 100 | 60 | 100 | 68 | 100 | 70 | 100 | 60 |

| Non flaming | ≤ | 200 | 140 | 200 | 145 | 200 | 135 | 200 | 130 |

| Acidity of gases evolved (pH) | ≥ | 4.3 | 5.6 | 4.3 | 5 | 4.3 | 5.2 | 4.3 | 6.1 |

| Conductivity of gases evolved | ≤μs/mm | 10 | 1 | 10 | 1 | 10 | 0.9 | 10 | 0.9 |

| Content of halogen acids | ≤ mg/g | 5 | 1 | 5 | 1.2 | 5 | 1 | 5 | 1 |

| Toxicity Index | ≤ | 2.5 | 1.1 | 2.5 | 1.2 | 2.5 | 1 | 2.5 | 1 |

| Thermal Impact Test | |||||||||

| Condition 150 degree C * 1h | No cracking | Pass | No cracking | Pass | No cracking | Pass | No cracking | Pass | |

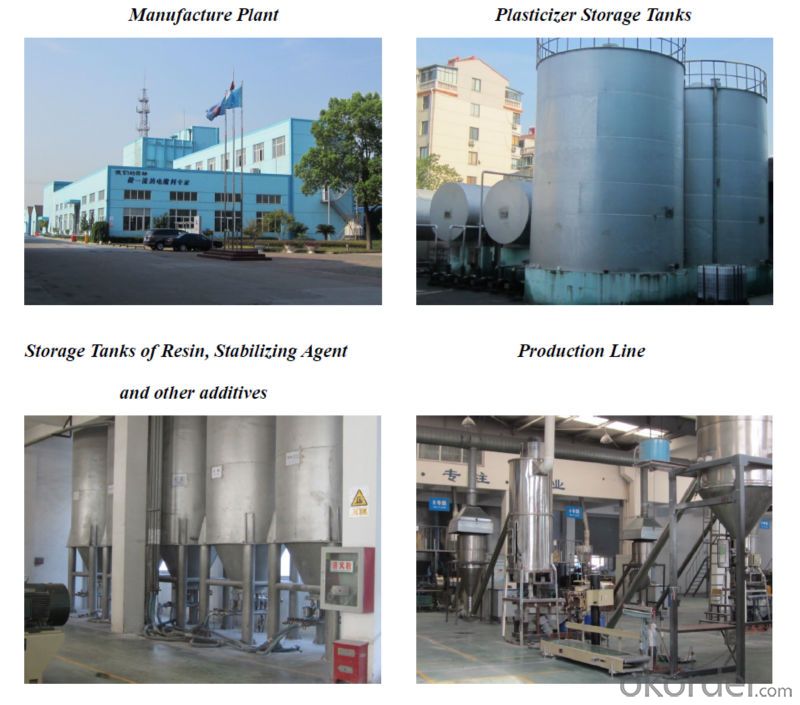

6. Company

- Q: Is plastic bucket and plastic bottle the same raw material?

- When the number of the triangle in the bottom of the plastic barrel is "3", the main component of the plastic barrel is polyvinyl chloride, also called PVC. This kind of plastic barrels can heat 81 DEG C, and the production process will use a lot of plasticizer (such as plasticizer, DOP) and heavy metal containing heat stabilizer, and the synthesis process is difficult to eliminate the presence of free monomer, these are considered to be toxic. Therefore, this kind of plastic bucket can not be placed people can eat directly, but also can not be recycled. Since the PVC used in this kind of plastic barrel is a kind of plastic which is not high temperature resistant, it can not be used in places where the temperature is higher.

- Q: Plastic PPT30S add what material will increase hardness?

- Commonly used talc and calcium carbonate increase the flexural modulus rather than the surface hardness. To increase surface hardness, a nucleating agent can be used. Moreover, talc and calcium carbonate can not be added to the injection molding, you must use the pumping equipment.

- Q: What is the concept of plastic raw materials for turnover containers?

- Suzhou Ke Reed plastic turnover box made of polypropylene, polyethylene synthesis, light weight, long service life, safety, non-toxic, tasteless, moisture-proof, corrosion resistance, light weight, durable, can be stacked, rich color, pure etc..

- Q: Plastic raw materials packaging is generally divided into several categories?

- 1, cattle cardboard fiber bag; "such as: GPPS, HIPS CMO ABS, are using this package, he is in some plastic packaging,2, fiber bags, plastic bags, such as PP or PVC, PE and so on3, plastic bags, Exxon, Teijin etc.4, plastic bags contain tin and platinum paper, for sealing requirements or moisture absorption of the material packaging5, kraft paper bags, PBT, PET, PPS, PA and so on

- Q: That kind of plastic bottle blows well

- PVCSoft, tough, good plasticity, can be made into transparent and various colors, commonly used transparent PVC packaging cosmetics categories of plastic bottles.

- Q: What is Ms plastic material?

- Transparent polymers were synthesized from methyl methacrylate (MMA) and styrene (SM) as the main raw materials.

- Q: PP plastic stool surface with those raw materials, what is the ratio?

- PP has good stress cracking resistance and has a high bending fatigue life, commonly known as "fold gum"".The comprehensive performance of PP is better than that of PE.

- Q: What material do you need for plastic film? Do you use this material?

- In addition, the bag color and performance requirements are not high, you can choose recycled polyethylene. Plastic can be recycled, because of the repeated use of processing, non-toxic, tasteless new plastic become cloudy, less than the original hygiene and color requirements. But this plastic bag is made from recycled material, which is environmentally friendly, and the price is 10% to 50% lower than that of the new material bag

- Q: What are the materials for making plastic basins? Are they raw materials?

- Generally PP material, transparent is raw material, opaque is not necessarily

- Q: I do PA, PC, PP and other plastic raw materials can be used in the eye frame and lens it

- There are PC lensesThe PC material is more impact resistant than polymer resin, often used in aviation equipment transparent windows, police on the mask, and the astronaut's helmet mask, it is only about 1/10 the weight of glass, resin lenses compared with traditional is only half of the weight.

Send your message to us

Low Smoke Halogen Free Flame Retardant Polyolefin Insulating Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords