Chemical Cross-linkable Low Smoke Zero Haogen Flame Retardant Polyolefin Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Polyolefin:

1. Applications and cable specifications of Polyolefin:

Used for cross-linked and insulating wires and cables of apparatus and instruments, equipments and etc.

Type | Product | Application and Cable Specification |

YJZD90 | 90℃ Chemical cross-linkable, low-smoke, halogen-free and flame retardant POE compound | Used for cross-linked and insulating wires and cables of apparatus and instruments, equipments and etc. |

YJZD105 | 105℃ Chemical cross-linkable, low-smoke, halogen-free and flame retardant POE compound | Used for cross-linked and insulating wires and cables of apparatus and instruments, equipments and etc. |

YJZD125 | 125℃ Chemical cross-linkable, low-smoke, halogen-free and flame retardant POE compound | Used for cross-linked and insulating wires and cables of apparatus and instruments, equipments and etc. |

YJZD150 | 150℃ Chemical cross-linkable, low-smoke, halogen-free and flame retardant POE compound | Used for cross-linked and insulating wires and cables of apparatus and instruments, equipments and etc. |

2. Description of Polyolefin:

Chemical cross-linkable POE compound for cables and wires, based on POE resin, is produced and pelletized by special technology with adding special stabilizing agent, modifier, halogen-free flame retardant, cross-linking agent and other special additives. The compound has well thermal deformation resistive and mechanical properties. It suits the cables and wires manufacturers who have rubber production lines, and need not irradiate.

3. Processing of Polyolefin:

The compound could be processed in common rubber extruder, and the recommended processing temperature is 100°C.The user could adjust the temperature properly according to extruder and wires and cables surface status.

Vulcanize processing of the compound could refer to rubber. The details of extrude speed, Vulcanize temperature and time could be adjusted properly according to the equipments and cross-linked status.

4. Storage and transport of Polyolefin:

Packing: 25kg/bag, PE membrane inside bag and craft outside bag.

Avoiding in direct sunlight and weathering.

Storage place should be clean, cool, dry and ventilated.

5. Properties of Polyolefin:

| Item | Unit | YJZD90 | YJZD105 | YJZD125 | |||

| Standard | Typical | Standard | Typical | Standard | Typical | ||

| Density | g/cm3 | -- | 1.46 | -- | 1.45 | -- | 1.45 |

| Hardness | Shore A | -- | 92 | -- | 91 | -- | 89 |

| Tensile Strength | ≥ MPa | 12.5 | 15 | 12.5 | 14.5 | 12.5 | 14.8 |

| Elongation at Break | ≥ % | 150 | 170 | 150 | 165 | 150 | 160 |

| Thermal Aging | |||||||

| Aging Temperature | degree C | 135±2 | 135±2 | 135±2 | 135±2 | 158±2 | 158±2 |

| Aging Time | h | 168 | 168 | 240 | 240 | 168 | 168 |

| Retention of Tensile Strength | ≥ % | 80 | 110 | 80 | 106 | 80 | 110 |

| Retention of Elongation at Break | ≥ % | 80 | 105 | 80 | 98 | 80 | 93 |

| Thermal Prolongation: 20N/cm2 | degree C×min | 200×15 | 200×15 | 200×15 | |||

| Elongation Under Load | ≤ % | 175 | 25 | 175 | 25 | 175 | 25 |

| Permanent Deformation | ≤ % | 15 | 0 | 15 | 0 | 15 | 0 |

| Volume Resistivity, at 20 degree C | ≥Ω*m | 1.0×1011 | 1.1×1012 | 1.0×1011 | 2.0×1012 | 1.0×1011 | 1.2×1012 |

| Dielectric Strength | ≥KV/mm | 20 | 24 | 20 | 24 | 20 | 25 |

| Oxygen Index | ≥ % | 28 | 32 | 28 | 32 | 28 | 33 |

| Impact Brittleness Temperature | degree C | -25 | pass | -25 | pass | -25 | pass |

| Smoke Density Flaming | ≤ | 100 | 66 | 100 | 67 | 100 | 67 |

| Non flaming | ≤ | 200 | 147 | 200 | 146 | 200 | 148 |

| Acidity of gases evolved (pH) | ≥ | 4.3 | 5.3 | 4.3 | 5.4 | 4.3 | 5.3 |

| Conductivity of gases evolved | ≤μs/cm | 2.5 | 1 | 2.5 | 1 | 2.5 | 1 |

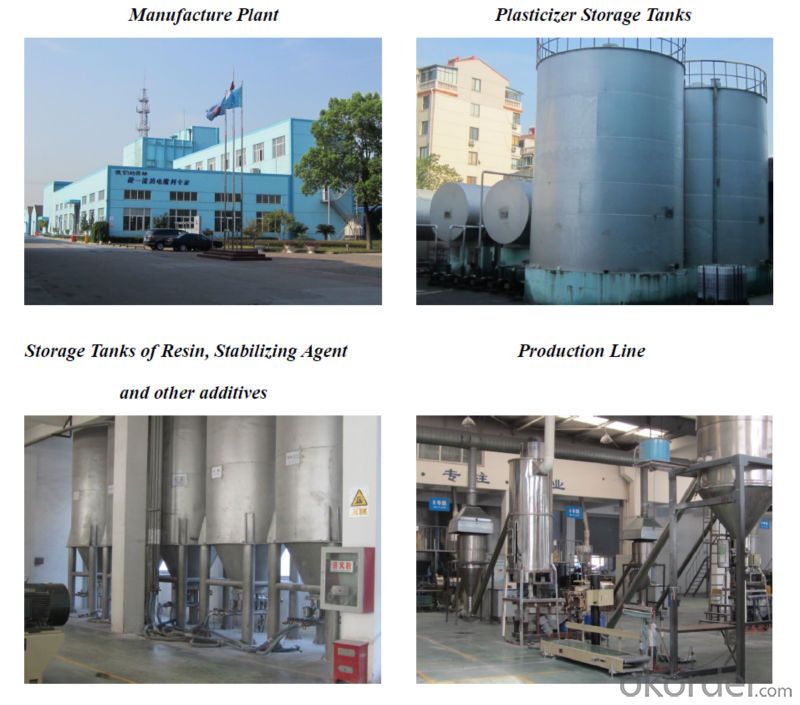

6. Company

- Q: What is the raw material used in the production of plastic products?

- Bearing cleaning supplies, plastic containers and bath products currently used in supermarkets and shopping malls in the plastic bag is made of this material, can resist high temperature of 110 DEG C, indicating the food use of plastic bags can be used for holding food. Bearing cleaning supplies, plastic containers and bath products can be repeatedly used carefully after cleaning, but these containers are usually not good cleaning, easy residual cleaning supplies, become a breeding ground for bacteria, it is better not to use circulation cleaning is not thorough so.

- Q: What are the raw materials of foam plastics and how do they come out?

- The foaming agents for epoxy resins are two types: physical foaming agents and chemical foaming agents. Physical foaming agents are mainly low boiling liquid, such as three chloro methane (F11), three chlorine, three fluorine ethane (F112), two chlorine, two fluorine methane (F12) and so on. By using the curing heat of the epoxy resin, the liquid with low boiling point is evaporated, and the gas is released, and the products are small in density and low in thermal conductivity. But fluorine hydrocarbons have a damaging effect on the atmosphere and are often used to spray foaming processes. According to the experts of China epoxy resin industry association, toluene and so on can be used as auxiliary foaming agent. In addition to foaming, it also acts as a curing reaction, a heat absorber and a diluent.

- Q: What material is the disc made of, metal or plastic?

- The CD disk has a substrate thickness of 1.2mm, a diameter of 120mm, a hole in the middle, and a circular shape. It is the shape of the disc. The reason why the disk can be taken at will depends mainly on the hardness of the substrate.

- Q: How many kinds of plastic do you have?

- B. foam:Foam plastics can be divided into three kinds of hard, semi hard and soft foam. Hard foam without flexibility, compression hardness is very big, only up to a certain stress deformation, stress the lifting of restitution; soft foam rich flexibility, compression hardness is very small, very easy to deformation, stress release after can restore the residual deformation small; semi rigid foam between flexibility and other properties between hard and soft foam.

- Q: What are the POE plastic raw materials?

- POE classification of plastics raw materials:Plasticizing properties: Thermoplastics and thermosetting plastics.Divided by use: General Plastics and engineering plastics.

- Q: What are the raw materials for making plastics?

- Plastic raw materials are extracted from some oil in the part of PC is most familiar with the material extracted from the oil, the PC material has a gasoline burning time; ABS is made from coal, ABS will show when soot like burn out; POM extraction from natural gas, POM will have a very smelly smell of gas when burned.

- Q: How do plastic raw materials trade? How big is the market?

- Traditional trading model is to realize the circulation of plastic raw materials with contacts, telephones and fixed customers. The Internet trading mode of transaction is transferred from the line to line, from order flow to terminal distribution capabilities are strong, with IT technology and services to provide information, plastic raw materials trading, a full range of logistics finance.

- Q: What are the APP of plastic raw materials?

- General plastics (polyethylene, polypropylene, polyvinyl chloride, polystyrene, ABS, etc.), thermosetting plastics (phenolic resin, epoxy resin, unsaturated polyester, polyurethane, silicone, amino resin, etc.);

- Q: What is the essential difference between plastic raw materials and engineering plastics?

- Plastics can be divided into two major categories: General Plastics and engineering plastics. They are usually granular or powder in order to be easy to process before they are madeGeneral plastics refer to common plastics with large output, wide use, good formability and low price. Such as PVC, polyethylene, polypropylene, polystyrene and so on. Products made of plastic film, pipe, woven bags and plastic daily necessities. The yield and consumption of general-purpose plastics account for more than 80% of all plastics.Engineering plastics refer to plastics that meet the needs of industrial parts. Relatively speaking, they yield large, wide range of applications. Mainly ABS, polycarbonate, nylon, POM, modified polyphenylene ether, thermoplastic polyester and so on. Products have TV casing, plastic gears, optical materials, gaskets and so on.There is also a special engineering plastics, in addition to its characteristics of engineering plastics, its comprehensive performance is higher, long-term use temperature above 150 degrees celsius. It also has special functions and special uses. Mainly used in high-tech industries, such as atomic energy, rockets, satellites, aerospace, automotive, electronic and sports equipment, and other structural materials. Commonly used special engineering plastics are fluorine plastic, silicon resin, polyimide, peek, liquid crystal polymer and so on.

- Q: What is the difference between PP raw material and modified PP?

- Sort:(1) according to the characteristics of resin when heating and cooling, classification: 1. Thermosetting plastics, two, thermoplastics(2) according to the use of plastics classification: general plastic, engineering plastics, special plastic raw materialsModified PPThe concept of modified plastic PP, refers to the base of the general plastics and engineering plastics, after filling, blending and enhancement processing method of modification, improve the performance of flame retardant plastic products, strength, impact resistance, toughness.Classification: PP modified plastic products are mainly a variety of flame retardant resins, toughening resin, plastic alloy, functional masterbatch etc..

Send your message to us

Chemical Cross-linkable Low Smoke Zero Haogen Flame Retardant Polyolefin Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches