K1 Class Irradiation Cross-linkable LSZH High Flame Retardant Polyolefin for Nuclear Power Cable

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

LSZH compound:

1. Applications and cable specifications of LSZH compound:

Type | Product | Application and cable specification |

HF111-1 | K1 class irradiation cross-linkable POE insulating compound for nuclear power cables | 1E grade K1 class irradiation cross-linkable non flame retardant inside insulation of nuclear power cables |

HF113-1 | K1 class irradiation cross-linkable low smoke halogen free high flame retardant POE insulating compound for nuclear power cables | 1E grade K1 class irradiation cross-linkable non flame retardant outside insulation of nuclear power cables |

HF113-7 | K1 class irradiation cross-linkable low smoke halogen free high flame retardant POE filling compound for nuclear power cables | 1E grade K1 class irradiation cross-linkable high flame retardant filling compound of nuclear power cables |

HF113-2 | K1 class irradiation cross-linkable low smoke halogen free high flame retardant POE jacket compound for nuclear power cables | 1E grade K1 class irradiation cross-linkable high flame retardant jacket of nuclear power cables |

HR113-2 | K1 class thermoplastic low smoke halogen free high flame retardant POE jacket compound for nuclear power cables | 1E grade K1 class thermoplastic high flame retardant jacket of nuclear power cables |

2. Description of LSZH compound:

low smoke halogen free flame retardant POE compound for nuclear power cable grade 1E class K1, based on POE resin, is produced and pelletized by special technology, adding special modifier, halogen-free flame retardant, anti-oxidant, crosslinking sensitizer and other special additives.

3. Processing of LSZH compound:

The following temperature(°C) profile of extruder is recommended:

| Type | Processing Equipment | Compression ratio | L/D | Processing temp. °C | Recommended vulcanize temp. | |||||

| Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die | |||||

| HF111-1 | Common rubber extruder | 1.1:1~1.5:1 | 20:1~25:1 | 90 | 140 | 160 | 165 | 165 | 160 | 10-15 megarad irradiation dosage |

| HF113-1 | 90 | 110 | 140 | 140 | 145 | 145 | ||||

| HF113-7 | ||||||||||

| HF113-2 | ||||||||||

| HR113-2 | 90 | 110 | 140 | 140 | 145 | 145 | ||||

4. Storage and transport of LSZH compound:

Packing: 25kg/bag, PE membrane inside bag and craft outside bag.

Avoiding in direct sunlight and weathering.

Storage place should be clean, cool, dry and ventilated.

5. Properties of LSZH compound:

| Item | Unit | HF111-1 | HF113-1 | HF113-7 | HF113-2 | HR113-2 |

| Standard | Standard | Standard | Standard | Standard | ||

| Tensile Strength | ≥MPa | 12.5 | 10 | 6 | 10 | 10 |

| Elongation at Break | ≥ % | 200 | 150 | 70 | 150 | 150 |

| Thermal Aging | °C×d | 135×7 | 135×10 | — | 135×10 | 110×10 |

| Variation on TS/ EB | ≤ % | ±25/±25 | ±30/±30 | — | ±30/±30 | ±25/±25 |

| Thermal Prolongation 20N/cm2 | °C×min | 200×15 | 200×15 | — | 200×15 | — |

| Elongation Under Load | ≤ % | 175 | 175 | — | 175 | — |

| Permanent Deformation | ≤ % | 15 | 15 | — | 15 | — |

| Volume Resistivity at 20 °C | ≥Ω.m | 1.0×1015 | 1.0×1012 | — | 1.0×1012 | 1.0×1012 |

| Dielectric Strength | ≥KV/mm | 25 | 20 | — | 20 | 20 |

| Oxygen Index | ≥ % | — | 30 | 40 | 30 | 30 |

| Impact Brittleness Temperature | °C | -30 | -30 | -15 | -30 | -30 |

| Smoke Density Flaming | ≤ | — | 100 | 100 | 100 | 100 |

| Non Flaming | ≤ | — | 350 | 350 | 350 | 350 |

| Acidity of gases evolved (PH) | ≥ | 4.3 | 4.3 | 4.3 | 4.3 | 4.3 |

| Conductivity of gases evolved | ≤μs/cm | 10 | 10 | 10 | 10 | 10 |

| Toxicity Index | ≤ | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 |

| Water Absorption Test | °C×h | 85×336 | 85×336 | — | 70×168 | 70×168 |

| Variation on TS/ EB | ≤ % | ±40/±40 | ±40/±40 | — | ±30/±30 | ±30/±30 |

| Ozone Resistance | No cracking | No cracking | No cracking | No cracking | No cracking | |

| Irradiation Test 3300KGy | No cracking | No cracking | No cracking | No cracking | No cracking | |

| Thermal Life | years | 60 | 60 | 60 | 60 | 60 |

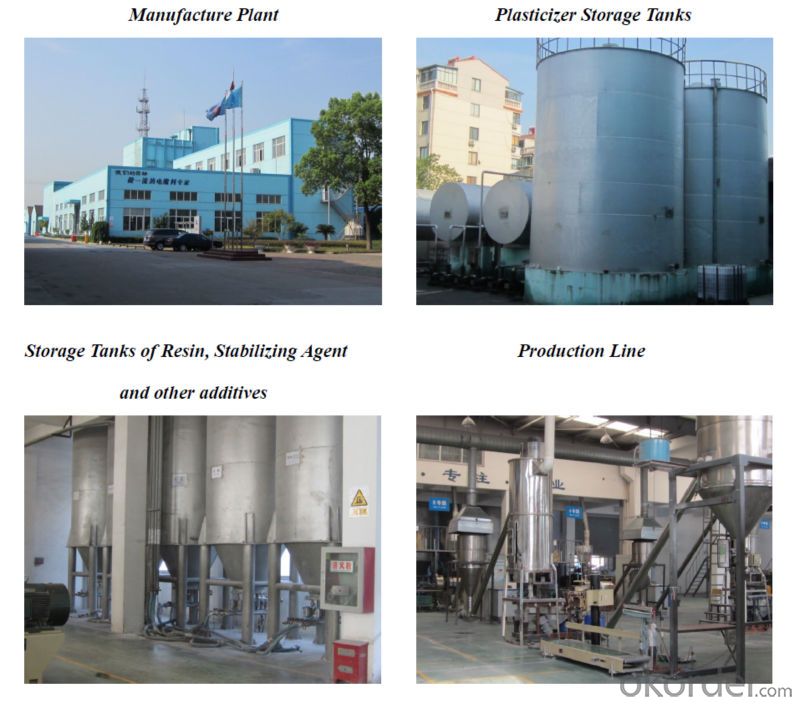

6. Company

- Q: Low pressure plastic raw materials in the process of blowing the two sides of the fold, how to deal with?

- The blowing ratio is one of the control points of blown film production and! Refers to the ratio between the bubble diameter and the diameter of not blowing blowing after.

- Q: Plastic raw materials packaging is generally divided into several categories?

- A variety of kraft paper, polyethylene thick film, fiber bags, aluminum foil bags

- Q: Dissolve in 0.3 of the LDPE plastic raw materials what?

- The molecular structure of the conventional LLDPE is characterized by its linear backbone, with only a few or no long branched chains, but contains some short branched chains. Without long branched chains, the crystallinity of polymers is higher.In general, LLDPE resins are characterized by density and melt index. The density is determined by the concentration of comonomer in the polymer chain. The comonomer concentration determines the short branch chain in the polymer. The length of the short branched chain depends on the type of comonomer. The higher the concentration of comonomer, the lower the density of the resin. In addition, the melt index is a reflection of the average molecular weight of the resin, mainly determined by the reaction temperature (solution method) and the addition of chain transfer agents (gas phase method). The average molecular weight is independent of the molecular weight distribution, and the latter is mainly influenced by the type of catalyst.

- Q: What is the plastic bag made of?

- Method for identification of toxic plastic bags. The water detection method: put a plastic bag into the water, non-toxic can be surfaced, and poisonous won't rise; hand touch detection method: white or colorless transparent is non-toxic, the hand has a sense of lubrication, the surface like wax; color detection method: toxic haze or color yellow, red, black, feel sticky; jitter method: take a plastic bag shaking, crisp sound non-toxic; sound stuffy astringent toxic.

- Q: What are the raw materials needed for producing plastic hair dryer shell and flashlight shell?

- The shell materials are ABS and PAABS material is acrylonitrile (Acrylonitrile), 1, 3- (Butadiene) and styrene butadiene (Styrene) three kinds of graft copolymer monomer, ABS plastic molding temperature is 180-250 DEG C, but preferably not more than 240 DEG C, the resin will be decomposed.

- Q: Application of CPE in plastics industry

- Chlorinated polyethylene (CPE) for saturated polymer materials, the appearance of white powder, non-toxic and tasteless, has excellent weather resistance, ozone resistance, chemical resistance and aging resistance, good oil resistance, flame retardancy and coloring properties.

- Q: How do plastic materials come from?

- Plastic has good insulation for electricity, heat and sound: electrical insulation, arc resistance, heat preservation, sound insulation, sound absorption, vibration absorption, noise elimination, and excellent performancePlastic raw materials are extracted from some oil in the part of PC is most familiar with the material extracted from the oil, the PC material has a gasoline burning time; ABS is made from coal, ABS will show when soot like burn out; POM extraction from natural gas, POM will have a very smelly smell of gas when burned.

- Q: What plastic material is resistant to high temperature?

- High temperature resistant plastic material:PPS: (PPS)Polyphenylene sulfide (abbreviated as PPS) is a new type of high performance thermoplastic resin. It has the advantages of high mechanical strength, high temperature resistance, chemical resistance, flame resistance, good thermal stability and good electrical performance. It is widely used in the fields of electronics, automobile, machinery and chemical engineering

- Q: What are the raw materials needed for making plastic bags?

- The bags made of two materials each have their own characteristics, and are chosen according to the purpose and performance of the products. Polyethylene is petrochemical products, prices vary according to crude oil and market conditions every day, at present LDPE (high pressure polyethylene) offer at 13500 yuan. HDPE (low pressure polyethylene) at 11000 yuan up and down.

- Q: Is plastic raw material rubber?

- Raw materials are polymers of polymers such as polypropylene. Is generally from the fossil raw materials inside the extraction after polymerization together. A series of plastic refers to the resin as the main component, such as plasticizers, fillers, lubricants, additives such as colorants as auxiliary components, can flow in the process of forming materials. To put it simply, the oil was extracted and finally made into plastic, rubber and plastic

Send your message to us

K1 Class Irradiation Cross-linkable LSZH High Flame Retardant Polyolefin for Nuclear Power Cable

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches