K3 Class Irradiation Cross-linkable LSZH Flame Retardant Polyolefin Compound for Nuclear Power Cable

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

polyolefin insulation:

1. Applications and cable specifications:

Type | Product | Application and Cable Specification |

HF311-1 | K3 class irradiation cross-linkable POE insulating compound for nuclear power cables | 1E grade K3 class irradiation cross-linkable non flame retardant inside insulation of nuclear power cables |

HF313-1 | K3 class irradiation cross-linkable low smoke halogen free high flame retardant POE insulating compound for nuclear power cables | 1E grade K3 class irradiation cross-linkable non flame retardant outside insulation of nuclear power cables |

HF313-7 | K3 class irradiation cross-linkable low smoke halogen free high flame retardant POE filling compound for nuclear power cables | 1E grade K3 class irradiation cross-linkable high flame retardant filling compound of nuclear power cables |

HF313-2 | K3 class irradiation cross-linkable low smoke halogen free high flame retardant POE jacket compound for nuclear power cables | 1E grade K3 class irradiation cross-linkable high flame retardant jacket of nuclear power cables |

HR313-2 | K3 class thermoplastic low smoke halogen free high flame retardant POE jacket compound for nuclear power cables | 1E grade K3 class thermoplastic high flame retardant jacket of nuclear power cables |

2. Description:

low smoke halogen free flame retardant POE compound for nuclear power grade 1E class K3 cable, based on POE resin, is produced and pelletized by special technology, adding special modifier, halogen-free flame retardant, anti-oxidant, crosslinking sensitizer and other special additives.

3. Processing:

The following temperature(°C) profile of extruder is recommended:

| Type | Processing Equipment | Compression ratio | L/D | Processing temp. | ||||

| Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | ||||

| HF311-1 | Common plastic extruder | 1.1:1~1.5:1 | 20:1~25:1 | 90 | 140 | 160 | 165 | 165 |

| HF313-1 | Common plastic extruder | 1.1:1~1.5:1 | 20:1~25:1 | 90 | 120 | 140 | 140 | 145 |

| HF313-7 | ||||||||

| HF313-2 | ||||||||

| HR313-2 | Common rubber extruder | 1.1:1~1.5:1 | 20:1~25:1 | 90 | 110 | 125 | 140 | 145 |

Note:Compound should be dried at 60-70°C before use, which has been stored more than two months.

4. Storage and transport:

Packing: 25kg/bag, PE membrane inside bag and craft outside bag.

Avoiding in direct sunlight and weathering.

Storage place should be clean, cool, dry and ventilated.

5. Properties:

| Item | Unit | HF311-1 | HF313-1 | HF313-7 | HF313-2 | HR313-2 |

| Standard | Standard | Standard | Standard | Standard | ||

| Tensile Strength | ≥MPa | 12.5 | 10 | 6 | 10 | 10 |

| Elongation at Break | ≥ % | 200 | 150 | 70 | 150 | 150 |

| Thermal Aging | °C×d | 135×7 | 135×10 | — | 135×10 | 110×10 |

| Variation on TS/ EB | ≤ % | ±25/±25 | ±30/±30 | — | ±30/±30 | ±25/±25 |

| Thermal Prolongation 20N/cm2 | °C×min | 200×15 | 200×15 | — | 200×15 | — |

| Elongation Under Load | ≤ % | 175 | 175 | — | 175 | — |

| Permanent Deformation | ≤ % | 15 | 15 | — | 15 | — |

| Volume Resistivity at 20 °C | ≥Ω.m | 1.0×1015 | 1.0×1012 | — | 1.0×1012 | 1.0×1012 |

| Dielectric Strength | ≥KV/mm | 25 | 20 | — | 20 | 20 |

| Oxygen Index | ≥ % | — | 30 | 40 | 30 | 30 |

| Impact Brittleness Temperature | °C | -30 | -30 | -15 | -30 | -30 |

| Smoke Density Flaming | ≤ | — | 100 | 100 | 100 | 100 |

| Non Flaming | ≤ | — | 350 | 350 | 350 | 350 |

| Acidity of gases evolved (PH) | ≥ | 4.3 | 4.3 | 4.3 | 4.3 | 4.3 |

| Conductivity of gases evolved | ≤μs/cm | 10 | 10 | 10 | 10 | 10 |

| Toxicity Index | ≤ | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 |

| Water Absorption Test | °C×h | 70×168 | 70×168 | — | 70×168 | 70×168 |

| Variation on TS/ EB | ≤ % | ±30/±30 | ±30/±30 | — | ±30/±30 | ±30/±30 |

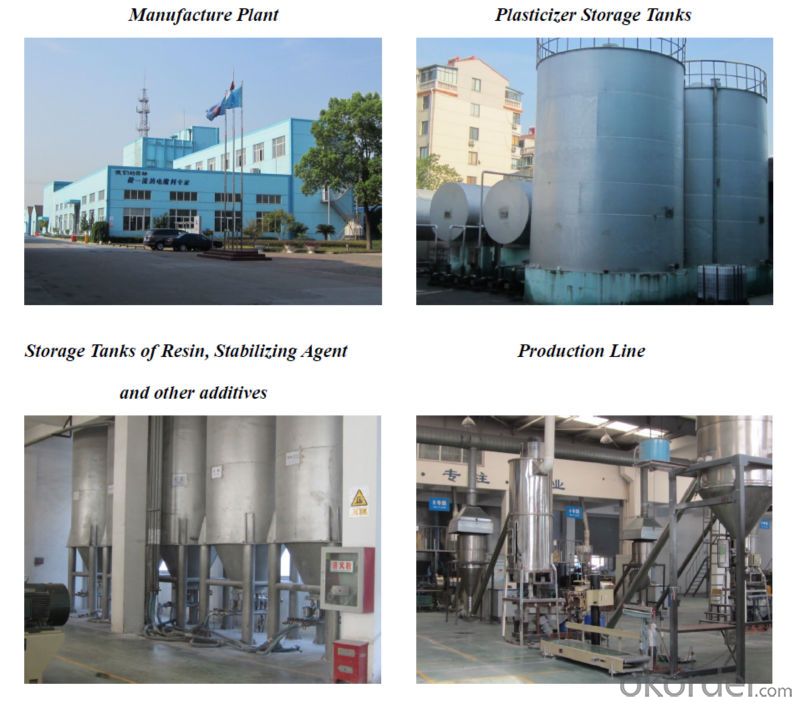

6. Company

- Q: Plastic raw materials packaging is generally divided into several categories?

- 1, cattle cardboard fiber bag; "such as: GPPS, HIPS CMO ABS, are using this package, he is in some plastic packaging,2, fiber bags, plastic bags, such as PP or PVC, PE and so on3, plastic bags, Exxon, Teijin etc.4, plastic bags contain tin and platinum paper, for sealing requirements or moisture absorption of the material packaging5, kraft paper bags, PBT, PET, PPS, PA and so on

- Q: What are the materials for making plastic buckets? How many are there?

- Domestic plastic bucket source material basically two kinds: blow molding with PE injection: PP

- Q: What is Ms plastic material?

- MS is a copolymer of methyl methacrylate and styrene. It has high transparency and toughness, and is better than PS (benzene, benzene).

- Q: Plastic raw materials are granular, why not powder?

- The powder is too choking! Add water to influence the effect of the product!

- Q: What raw material produces the plastic to the human body not to harm, to the environment does not have the pollution?

- For example, light degradable plastics manufacturing methods can be divided into light degradable plastics synthetic degradable plastics and adding degradable plastics. A, ethylene copolymer / carbon monoxide (E/CO) photodegradation to ketone backbone fracture characteristics of.E/CO light degradation speed and degree and the amount of the chain, the higher the content, the degradation rate of the soon, the greater. The United States of Texas, scientists have to E/CO for outdoor exposure experiments in sunny June, the fastest E/CO only a few days can be degraded. B, ethylene / vinyl ketone copolymer (Ecolyte) keto Ecolyte molecules on the side chain can be decomposed to.Ecolyte light the degradation performance is better than E/CO in the role of natural light, but the cost is higher. This kind of polymer drawback is once see the light starts to degrade, almost no induction period, need adding antioxidants to regulate the induction period Purpose. (2) add type light degradable plastics additive light degradable plastics with a small amount of photosensitizer in the polymer, at low concentration is the degradation of photocatalytic oxidation by solar irradiation (Zi Waiguang) and react to the polyolefin polymer fracture. In PE, PP polymers such as ketones, amines and adding photosensitizer can good photodegradability. Add light degradable plastics with low cost, simple production process, do mulching better. But the degradation characteristics of the exposure surface degradation more thoroughly, some less degradation buried in the soil. The degradation of this kind of photodegradable plastics can be controlled in the induction period of two months or more. But the degradation time control is poor.

- Q: ABS plastic storage conditions

- If it is ABS raw materials, storage: rainproof, moisture-proof, anti lightPacking is best provided with a PE inner bag for moisture proofThere is no place to pay more attention.

- Q: What are the raw materials needed for making plastic bags?

- In addition, the bag color and performance requirements are not high, you can choose recycled polyethylene. Plastic can be recycled, because of the repeated use of processing, non-toxic, tasteless new plastic become cloudy, less than the original hygiene and color requirements. But this plastic bag is made from recycled material, which is environmentally friendly, and the price is 10% to 50% lower than that of the new material bag

- Q: PP plastic stool surface with those raw materials, what is the ratio?

- PP has good stress cracking resistance and has a high bending fatigue life, commonly known as "fold gum"".The comprehensive performance of PP is better than that of PE.

- Q: What two ingredients fit together to solidify like plastic?

- What is the material of plastics? This is important because even the adhesive with high bond strength can not be well adhered to on some surfaces, such as PTFE.

- Q: What are the materials for making plastic basins? Are they raw materials?

- The plastic washbasin is made of PP plastic(polypropylene is a thermoplastic resin made by the polymerization of propylene.)Is a relatively traditional washbasin, anti wrestling performance is very strong.Although the modern bathroom, a variety of shapes, materials, fashion basin are,But still can not do without this traditional plastic basin.

Send your message to us

K3 Class Irradiation Cross-linkable LSZH Flame Retardant Polyolefin Compound for Nuclear Power Cable

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches