LDPE Geomembranes with Thickness of 1.0mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

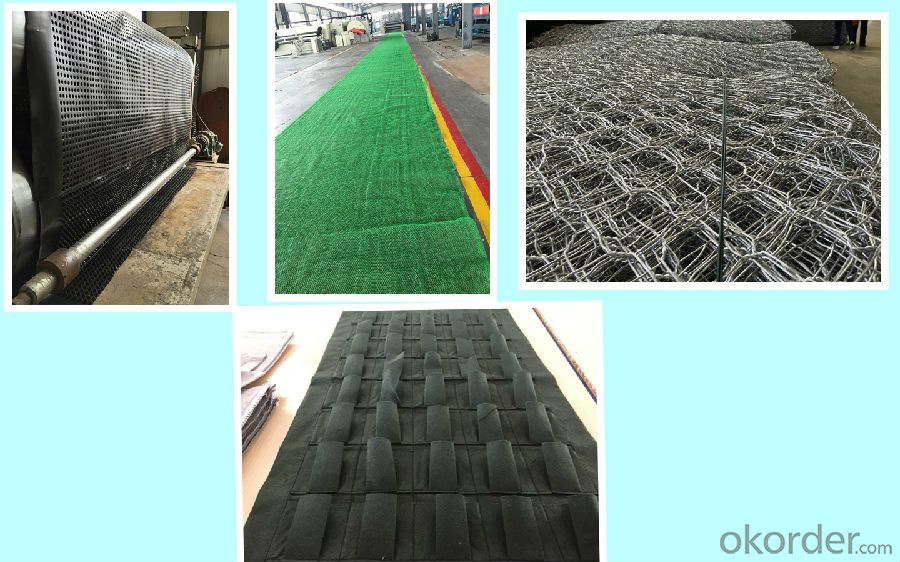

LDPE Geomembranes

Products Description

Made from LDPE, LLDPE, EVA resin and additives such as antioxidant, carbon black, master batch etc with the method of 1 layer extrusion and 3 layers co-extrusion in high temperature.

Product Application

1. Agricultural water conservancy projects.

2. Ponds for aquaculture.

Product Advantages:

1. High flexibility, high waterproof coefficient.

2. Could be used in the temperature of -70 ℃~110 ℃.

3.Good stability, anti acid and alkalis,anti-erosion.

4.High climate bearing ability, excellent in anti-aging.

5.High tensile strength and elongation, can be used in bad geology and climate, especially be used in the soil uneven sedimentation.

6.High friction coefficient.

Product Specification

1. Thickness: 0.1mm to 3.0mm.

2. 4m-9m in roll width, roll length as design or client's request.

Products Characteristics

1.HDPE performs well in mechanical properties ,ageing-resistance , chemical-resistance ,climate- resistance and resistance to puncture .

2.LDPE & EVA feathers great elongation, good flexibility at low temperature, softness and easy installation.

3.ECB ,high-class waterproofing rolls, is formed by combining ethylene polymer with oil-resin.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q: How do geomembranes contribute to sediment control in construction sites?

- Geomembranes contribute to sediment control in construction sites by acting as a barrier between the construction activities and the surrounding environment. They prevent sediment from washing away into nearby water bodies, thereby minimizing soil erosion and sediment pollution. Geomembranes also help in containing and managing sediment runoff, allowing for easier sediment removal and proper disposal.

- Q: How do geomembranes prevent water pollution in mining tailings management?

- Geomembranes prevent water pollution in mining tailings management by acting as a barrier between the tailings and the surrounding environment. These impermeable liners are specifically designed to prevent the seepage of contaminants, such as heavy metals and chemicals, into nearby soil and water sources. By effectively containing the potentially harmful materials within the mining site, geomembranes help safeguard the surrounding ecosystems and prevent water pollution.

- Q: Are geomembranes resistant to chemical solvents?

- Yes, geomembranes are generally resistant to chemical solvents. They are specifically designed to provide a barrier against chemical attacks and are commonly used in applications where exposure to various chemical solvents is expected. However, the specific resistance may vary based on the type and concentration of the solvent, as well as the material composition of the geomembrane. It is important to consult the manufacturer's specifications and guidelines to ensure proper compatibility with specific chemical solvents.

- Q: how to construct composite geo-membrane and two cloths film one film?

- Construction technology of two cloths one membrane, and the connective way of two cloth one membrane edges. ① membrane and membrane's welding, non-woven cloth seams, seams film is departed with the cloth, it can't be synchronizely stressed, seam strength is 20-40% of the base materials, the connective way of two cloths film one film edges. ① membrane and membrane's welding, non-woven fabrics' seams, seam film is departed from the cloth, and can't stand synchronized force.

- Q: How do geomembranes contribute to water conservation?

- Geomembranes contribute to water conservation by acting as impermeable barriers that prevent water from seeping into the ground. They are frequently used in various water containment applications such as reservoirs, ponds, and canals, effectively reducing water loss through seepage and evaporation. Additionally, geomembranes are often employed in lining systems for landfills, preventing the contamination of groundwater by leachate. Overall, by minimizing water loss and contamination, geomembranes play a crucial role in conserving water resources.

- Q: How to stick membrane on the cabinet?

- The membrane is very cheap. Spray the door before you begin to stick the membrane to avoid bubbles. Then measure the size of the area where you want to stick membrane and tailor the membrane you bought according to the size. To avoid waste, a draft is recommended. Finally, stick the membrane from up to down gradually and check at all times to prevent the membrane from being slantways stuck.

- Q: in what areas does geomembrane usually apply? Please recommend cost-effective geomembrane.

- Clean water such as reservoir, and the pool also uses flexible impermeable geomembrane which is a typical representative of the flexible seepage proof material. seepage-proof geomembrane is preferable to a large area needs leakage pollution prevention like residue field. Cost-effective. The advantage is to prevent liquid leakage, mining waste water, sewage, petrochemical wastewater.

- Q: Does Electrothermal membrane emit heating radiation?

- The power supply is connected to temperature controllor through wire and control room temperature between 0-35 degrees. Because the electric heating film is a pure resistance circuit, which is highly efficient in transfering electric energy into heat energy, and can release far infrared wave when releasing heat.

- Q: What should be noticed when geomembrane is welding?

- The success of sewage treatment seepage control project depends on the quality of the geomembrane itself and the quality of its installation and construction.

- Q: How do geomembranes perform in high altitude gas containment applications?

- Geomembranes perform well in high altitude gas containment applications. They are designed to withstand extreme conditions and are highly resistant to gas permeation, ensuring effective containment of gases at high altitudes. Additionally, their durability and flexibility make them suitable for various terrains and climates, making them a reliable choice for gas containment in challenging environments.

Send your message to us

LDPE Geomembranes with Thickness of 1.0mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords