LLDPE Geomembranes with Thickness of 1.0mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

LLDPE Geomembranes

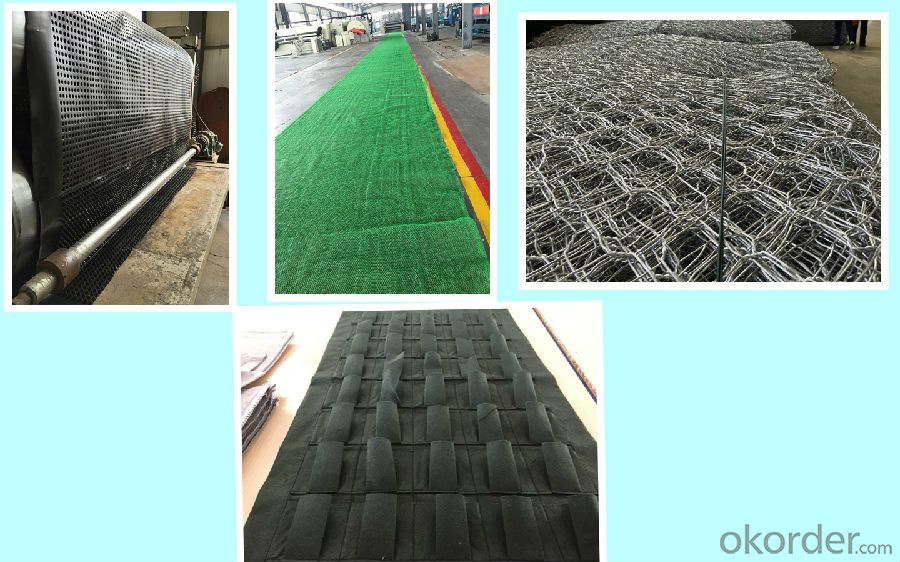

LLDPE Geomembranes Description

Made from LDPE, LLDPE, EVA resin and additives such as antioxidant, carbon black, master batch etc with the method of 1 layer extrusion and 3 layers co-extrusion in high temperature.

LLDPE Geomembranes Application

1. Agricultural water conservancy projects.

2. Ponds for aquaculture.

LLDPE Geomembranes Advantages:

1. High flexibility, high waterproof coefficient.

2. Could be used in the temperature of -70 ℃~110 ℃.

3.Good stability, anti acid and alkalis,anti-erosion.

4.High climate bearing ability, excellent in anti-aging.

5.High tensile strength and elongation, can be used in bad geology and climate, especially be used in the soil uneven sedimentation.

6.High friction coefficient.

LLDPE Geomembranes Specification

1. Thickness: 0.1mm to 3.0mm.

2. 4m-9m in roll width, roll length as design or client's request.

LLDPE Geomembranes Characteristics

1.HDPE performs well in mechanical properties ,ageing-resistance , chemical-resistance ,climate- resistance and resistance to puncture .

2.LDPE & EVA feathers great elongation, good flexibility at low temperature, softness and easy installation.

3.ECB ,high-class waterproofing rolls, is formed by combining ethylene polymer with oil-resin.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q:What are the advantages of using geomembranes in desalination and water treatment plants?

- There are several advantages of using geomembranes in desalination and water treatment plants. Firstly, geomembranes act as a barrier that prevents the leakage of treated water, ensuring that the water is stored and transported safely. Secondly, these membranes are highly resistant to corrosion and chemical degradation, which helps to maintain the quality and longevity of the treatment infrastructure. Additionally, geomembranes are flexible and can be easily installed, reducing construction time and costs. Lastly, these membranes also provide protection against the contamination of soil and groundwater, thus preserving the environmental integrity of the surrounding areas.

- Q:Can geomembranes be used in hydroelectric power plants?

- Yes, geomembranes can be used in hydroelectric power plants. They are commonly used in various applications within these plants, such as lining water reservoirs, canals, and penstocks. Geomembranes provide an effective barrier to prevent water leakage and seepage, ensuring the integrity and efficiency of the hydroelectric power plant infrastructure.

- Q:How do geomembranes contribute to soil moisture retention?

- Geomembranes contribute to soil moisture retention by acting as a barrier that prevents water from evaporating or infiltrating into the ground. This helps to create a more consistent and controlled moisture level in the soil, reducing water loss and promoting plant growth. Additionally, geomembranes can also prevent excessive water runoff, allowing the soil to retain more moisture for longer periods of time.

- Q:how is the effect decoration color film.

- Very good! Color film is a new reinforced glass decorative materials, color film broke the previous traditional process that uses major pictorial material to strengthen the glass as decorative materials, replacing an enhanced pictorial material that dominated the glass sliding doors, glass cabinets, glass and other glass decorative backdrop materials. Glass color film with enhanced pictorial material no advantage: 1, color film made of tempered glass finished glass has high safety, after such a color film glass glass products, when the product was crushed, no glass fragments It will be like the usual glass littered, but all the pieces are glued to the glass color film, so you can ensure the safety of users guarantee the broken glass. 2, tempered glass color film having a high environmental protection. In the past pictorial material reinforced with glass, many of which are reinforced by a number of pictorial material volatile substances and toxic substances to be made, the finished product is made with an very strong toxic, not only to the workers this long accumulated in the processing of glass easy poisoning, after which the user in such a room to stay for a long time are likely to be poisoned at varying degrees , while the glass color film is the application of advanced inks and more environmentally friendly material, and has no toxicity.

- Q:What are the design considerations for geomembranes in floating covers for wastewater treatment plants?

- The design considerations for geomembranes in floating covers for wastewater treatment plants include factors such as the material's chemical resistance, durability, flexibility, and puncture resistance. Additionally, the geomembrane's ability to withstand UV exposure, temperature fluctuations, and mechanical stress is crucial. It is also important to consider the installation process, including the need for proper anchoring and sealing to ensure the cover's stability and prevent leakage. Overall, the selected geomembrane should meet the specific needs of the wastewater treatment plant in terms of performance, longevity, and environmental safety.

- Q:Is there any impact on mobile phone to stick the film?

- Certainly not. It can prevent the phone from being scratched. There is a film on the screen when you buy the phone. The general film is not bad, it just make the sensitivity of handwriting lower, which can be ignored. Inferior screensavers are sticky, which will corrode the screen

- Q:What is the stick membrane method on the wall?

- 1. the hair dryer can be adjusted to the hot air grade to blow soft the paster, while blowing, you should expose the paper, and be careful not to blow coke paper, otherwise it will be cut off, the control just right to blow the glue soft state, the heat transfer can be appropriately adjusted to small grade . 2. it can be injected alcohol from a corner , not too much, let the glue inside softening , until it can be peeled off, but this method has met the original background wall may affect the original background, we need to choose the method according to the actual situation. 3. For the metal wall you can also use a similar chemical solvents such as acetone, with quick cleaning speed, good effect, but ordinary wall is not recommended. 4. For hard tile wall with a thin blade can also be scraped off the sticker applied to a small area of ??the sticker.

- Q:How to calculate the power consumption of the electric heating film?

- To measure the DC resistance and square the rated voltage divided by the DC resistance, then the power is calculated. The electric heating film is divided into high temperature and low temperature electric heating film. The high temperature electric heating film is generally used in electronic, military and so on. The electrothermal?film produced by the Today Technology. The low temperature electric film is a semitransparent polyester film after it is powered. It is made of by the special conductive ink. It is processed by the metal carrier and made between the insulating polyester film. When working, it takes the electrothermal?film as the heating element and sends heat into the space in the form of radiation. It can first make people's body and the objects to get the heat. It's integrated effect is far better than the traditional method of convection heating. The low-temperature radiant electric heating film system is composed of a power supply, a temperature controller, a connecting piece, an insulating layer, an electric heating film and a facing layer. The power supply is connected with an electric heating film through a conducting wire, and the electric energy is converted into heat energy. Because the electric heating film is a pure resistance circuit, the conversion efficiency is high, in addition to a small partial loss (2%), the vast majority (98%) is converted into heat energy. The electrothermal membrane can not be directly for the radiant floor heating, requiring additional patent PVC vacuum envelope, it can be used in floor heating to ensure the use of effects and life. The development potential of electric heating film is huge, which is consistent with the trend of low carbon economy development.

- Q:Can geomembranes be used for geotextile protection?

- No, geomembranes cannot be used for geotextile protection. Geomembranes are impermeable liners used to contain fluids or prevent seepage, while geotextiles are permeable fabrics used for filtration, separation, or reinforcement purposes.

- Q:What is the classification of film resistance?

- Thin film resistor is a kind of high precision resistor. Thin film resistor is different from the thick film chip resistor and the latter dominates the market. It is a thin film chip fixed resistor with high accuracy and low temperature coefficient. Thin film resistor is made by evaporating a resistivity material on the surface of an insulting material, and the insulting material of such resistor is generally ceramic substrate. Thin film resistor is made by evaporating a certain resistivity material on the insulating material, and the major categories are: 1. The carbon film resistor is made by depositing crystallize carbon on a ceramic rod framework. Carbon film resistors have low cost. Stable performance. Wide resistance range. It has low temperature coefficient and voltage coefficient, and is the most widely used resistor at present. 2. The metal film resistors. Coating the alloy material on the surface of the ceramic rods framework by vacuum evaporation . Metal film resistors have higher precision, good stability, and low noise and temperature coefficient than carbon film resistors, thus is widely applied in the instrumentation and communications equipment. 3. Metal oxidation film resistors is made by deposited a metallic oxide layer on the insulating rod. Because it itself is an oxide, it is stable at high temperature and thermal shock resistance with strong load capacity. 4. The synthetic membrane resistor is made by coating the conductive composite suspension liquid on the substrate, therefore, it is also called paint film resistor. Due to its grainy structure of the conductive layer, it produces a lot of noises, and has low precision. It is mainly used in the manufacturing of resistors with high pressure and resistance and small resistors.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

LLDPE Geomembranes with Thickness of 1.0mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords