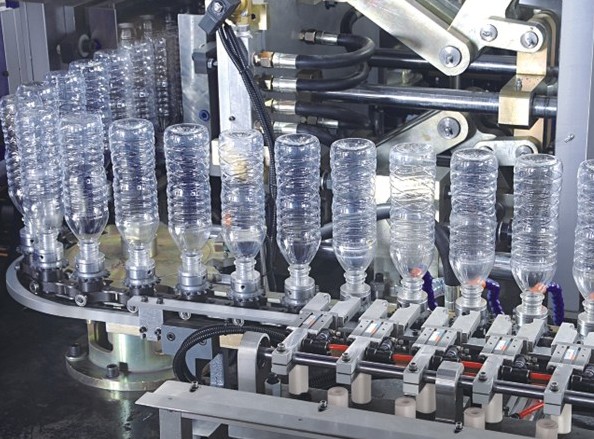

Full automatic PET bottle blow molding machine

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

blow molding machine

Features:

Automatic perform input and ready bottle output system.

Machine adopt with the overall structure of super-standard anti-vibration design, high-speed operation state of the machine will shake down to a minimum.

Machine adopts modular assembly method, greatly decrease the local amendments due to technological improvements when the machine is on processing.

The structure of machine oven adopt the international most advanced energy-saving technology of infrared radiation heating, temperature control with automatic negative feedback, closed-loop regulation model.

Automation controlling item adopts international high-end computer system, heating, collecting and measuring perform temperature with simulation input and output module.

Man-machine interface displays current production situation, available for on line switching, parameter modification and production accounting, with automatic alarm, automatic fault detection and diagnose.\function.

Description for machine

TYPE | ITEM | UNIT | ZS-F2 | ZS-F3 | ZS-F4 |

CONTAINER | Number of cavity | Cav. | 2 | 3 | 4 |

Theoretical output | Pcs/Hr | 2000 | 3000 | 4000 | |

Max.container volume | L | 2.0 | 2.0 | 2.0 | |

Max.neck diameter | MM | 45 | 45 | 38 | |

Max.container diameter | MM | 110 | 110 | 100 | |

Max.container height | MM | 330 | 330 | 330 | |

ELECTRICAL SYSTEM | Installation power | KW | 27 | 48 | 56 |

Max.heating power | KW | 24 | 42 | 54 | |

Actual power consumption | KW | 15 | 24 | 30 | |

MACHINE | Main machine dimension | M | 3.1x1.7x2.3 | 3.2x1.8x2.3 | 3.6x2.1x2.3 |

Feeding machine dimension | m | 2.1x1.3 x.2.5 | 2.1x1.4 x.2.5 | 2.1x1.4 x.2.5 | |

Main machine weight | KG | 2200 | 2200 | 3000 | |

Feeding machine weight | KG | 250 | 260 | 260 |

Company Information

blow molding machine

ZS factory

ZS sample room

Our Services

1.your inquiry related to our product & price will be replied within 24hours.

2.Well-trained & experienced staff are to answer all your inquires in English of course.

3.OEM&ODM projects are highly welcomed. We have strong R&D team here to help.

4.Your business relationship with us will be confidential to any third party.

5.Good after sale service offered, please get back if you got question.

FAQ

Q: Payment

A: 30% T/T as down pament, 70% by T/T before shopment

Q:Delivery time

A:30 days after down payment

- Q: What is the working principle of the vacuum oil filter?It's easy to understand

- The gasification temperature of oil and water is different. Working in a vacuum can improve efficiency and control temperature to remove moisture in the oil

- Q: Points for attention of vacuum oil filter

- Application and notice of vacuum oil filter2.1 because the vacuum oil filter is used less (one or two years only last time), therefore, the operator should read the instruction carefully before operation, and must be familiar with the operation method of the oil filter.2.2 operate strictly according to the order of instructions and strictly control the oil level of the tank to prevent the oil from being absorbed into the vacuum pump.2.3, the oil temperature is generally controlled at 40~60 degrees (except for instructions).2.4, the use of oil filters are often checked, the oil pipe joints, valves are blocked, oil spills, such as the breakdown should immediately stop inspection, processing. Anti static earthing measures shall be adopted for the oil filter and the metal piping of the oil system.2.5 during the operation of the vacuum oil filter, when the outlet oil pressure is greater than 0.3Mpa, the reasons should be checked. When the plug is stopped, the filter components can be stopped, cleaned or replaced.2.6, operators must be strictly responsible for the work, serious and responsible, on duty, shall not do other irrelevant things.

- Q: How often is the filter element of the transformer oil vacuum oil filter changed?

- Usually a good filter can be cleaned and reused later until it is broken. Some are changed only once a year, and some half a year, according to the oil,

- Q: Comment: what's the difference between a vacuum oil filter and a centrifugal oil filter?

- The difference between the 1, the technical principle: vacuum oil filter mainly adopts vacuum pump, artificial vacuum in the vacuum tank, realize the separation of different heating flash level under vacuum, the use of oil, water, gas, acid and other hydrocarbons; and the centrifugal oil filter machine mainly uses high speed centrifugal machine from to realize oil-water separation and impurity separation principle, and washing machine water shedding of exactly the same, very simple.

- Q: Use vacuum oil filters to filter transformer oil in summer and winter temperature should be in the degree of the northern region

- Using filtered vacuum oil filter oil pressure: you said, the south region of 10# transformer oil, transformer oil 45# used in northern area, southwest area using 25# transformer oil, due to the temperature difference in the north south, the summer temperature of outdoor temperature at 35 degrees, 20 degrees below zero in winter, the supplier will consider the temperature difference

- Q: Can centrifugal oil filters filter sesame oil? What's the filtration effect?

- Can filter, the effect is good, centrifugal oil filter is specialized in cooking oil

- Q: What's the difference between an oil filter and an oil press?

- The oil in the wok heating material first, let the material molecular re combination again into the press in the press, by squeezing out oil, commonly known as the "oil", the crude oil containing substances affect human health, to his oil filter filter, after filtering the oil can be eaten.

- Q: How to separate the rapeseed oil with centrifugal oil filter, how to use in the separation, how to use the water.

- There is a double shaft type in high precision centrifugal filter device, only produced by the lubricating oil filter pressure to provide the driving force, its speed can reach more than 7000r.p.m.

- Q: Why is there a load switch, no oil filter?

- On load switch has oil filter, oh, there is a very small flow capacity DZX switch on line filter

- Q: How to select oil filter in small hydropower station?

- ZL insulated oil regeneration special vacuum Purifier - vacuum oil filter or transformer oil on-line processing high precision Trinity oil filter.

Send your message to us

Full automatic PET bottle blow molding machine

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches