PC Hollow Sheet Extrusion Line/plastic Sheet making machines/pvc plastic sheet extruder

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Features

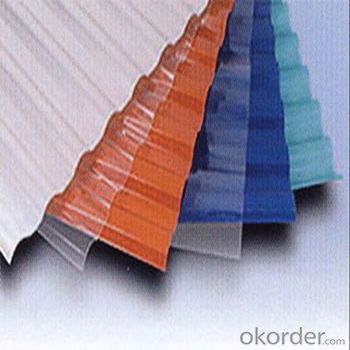

1.Light Transmission

The light transmission reaches 12%-82% depending upon color and thickness.

2.Thermal Insulation

Proprietary hollow from contributes to reduce the energy consumption and therefore energy costs.

3.Fire resistance

4.According to GB8624-1997 the fire retardant classification of POLYGAL project sun sheet is B1.

4.Impact resistance

Its outstanding roughness offers greater protection against breakage during transportation, installation and usage. The impact strength is 10-27 times as much as fiberglass.

5.UA-Protection

Attributing to the proprietary UV surfaces. Remain perfect mechanical adoption properties after exposed to extreme weather for a long time.

6.Sound Insulation

The hollow from and polycarbonate resin offer significant advantage to the sound insulation.

7.Weather Ability

It have good weather ability can maintain excellent properties in a wide temperature range form -40* to 120*.

Applications

1.Roofing light sheet and sunshade for office building polystyrene foam sheet extrusion line

2.Skylight, lighting for corridors, balcony, passages and subway entries, walkways

3. awning, canopy.

4.Advertising lamp boxes, sign board, polystyrene foam sheet extrusion line

5.Anti-riot shield, bullet resistant material, Bank ATMs.

6.Conservatories, agricultural greenhouses, zoos, botanical gardens.

7..Industrial Roofing and Glazing

8..Industrial Roofing and Glazing

9.Unusual decorations, corridors

10.Interior and exterior decorations of commercial buildings

11.Interior and exterior decorations of commercial buildings

12.Telephone booths, street name plates and sign boards

13.Roofing skylight for office building, department store, hotel, stadium, school, hospital.

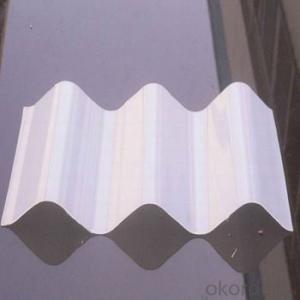

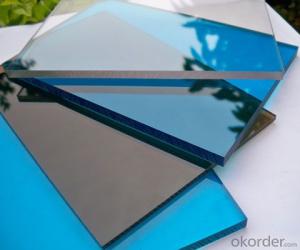

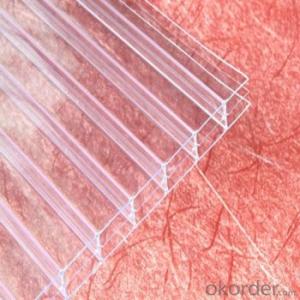

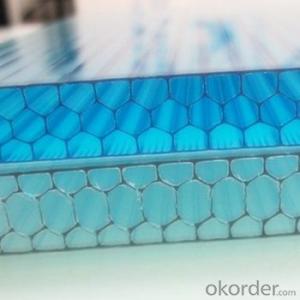

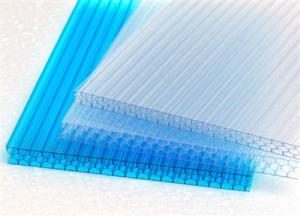

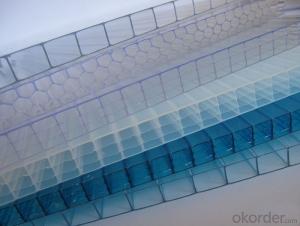

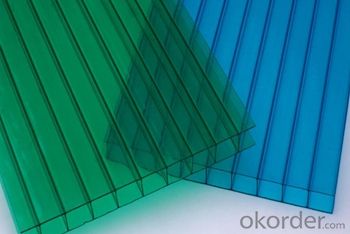

Product Pictures

- Q: Which friends know how to remove the plastic film on the sun?

- Generally can be removed by hand But should pay attention not directly under the sun exposure, or may lead to thin film too thin, not easy to tear. After the installation of sun panels, should immediately tear off the film

- Q: How to correctly identify the quality of pc sunshine board and pc durability plate method

- Pull the protective film to see the sheet. Particles or bubbles are relatively small or relatively small, indicating that the recovery of raw materials, but is a good back to the material, this board is the middle grade plate. Such as bubbles and particles more or larger, indicating that the poor raw material, this board is a low-grade plate. If the civilian particles or particles rarely, that the quality of the sun plate is very good, is ten years of quality.

- Q: To build a sunshine shed, with Cortron PC patience board or good sun board?

- 1, Cortron sun board Advantages: the German Bayer new materials and co-extruded high concentrations of UV, yellowing effect is good light Light, cover the sun room effect is good 2, Cortron Nai Liban Advantages: good light transmission, up to 88% Good temperature resistance, at minus 40 degrees Celsius to 120 degrees Celsius, there will be no deterioration of quality Sound insulation is good Flame retardant, light weight, safe

- Q: How much of the installation of the sun board installation of a square meter

- An effective space must be provided in the connection profile or in the mounting groove of the frame so that the plate is subject to expansion and load displacement. The linear thermal expansion coefficient of the hollow sun plate is 7 × 10m / mk, that is, the temperature of each 1 ℃, 1m × 1m board along the length of the expansion of 0.075mm, the user should be based on the location of the four quarters of the temperature difference between the calculation of the installation gap data: Such as the northern region, the maximum temperature of 40 ℃, the minimum temperature of -30 ℃, 1m × 1m of the plate to install the gap is 0.07 × 70 = 4.9mm

- Q: PC sun board life years?

- In fact, the warranty period of the sun board is the warranty of the yellowing index, depending on the UV (UV stabilizer) into the number of cases, under normal circumstances, 50μ UV yellowing index warranty for 10 years

- Q: Project sun board price how much

- Thickness 16mm - 40mm, the price is generally 80 yuan - 260 yuan / ㎡, this interval thickness of the PC sun panels generally use less, but also a variety of shapes. Global PC sunshine board prices are different.

- Q: What can I do with my own sunshine board?

- Can make their own small greenhouse room, the balcony can be used to do sunrise sun awning.

- Q: Company pc sunshine board how to solve the problem

- The use of PC on the buckle, aluminum alloy buckle up and down, this method of dealing with a little higher cost of seams, but simply can bear, but if it is bow high bow stent device is difficult.

- Q: Can the sun board cover the bedroom?

- At the time of installation, the organizer of the construction must understand the text description and precautions printed on the protective film and explain to the operator, with particular attention to which side of the standard. Do not wrong. Sun board for the polycarbonate transparent plate of the trade name, referred to as PC board, is widely used in the international high-strength, light transmission, noise, energy-saving new decorative materials. It has a light, weather, super, flame retardant, sound insulation of the excellent performance, access to architectural design, decoration works, environmental engineering, advertising industry widely recognized.

- Q: Sunshine board price per square meter, PC sun board how much money a square meter

- PC sunshine board price is not constant price, but a comprehensive consideration of technical process level, sheet performance, then the raw material prices and other costs through the calculation.

Send your message to us

PC Hollow Sheet Extrusion Line/plastic Sheet making machines/pvc plastic sheet extruder

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords