pvc/pe/pp extrusion machine acrylic sheet extruding sex film extruder machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

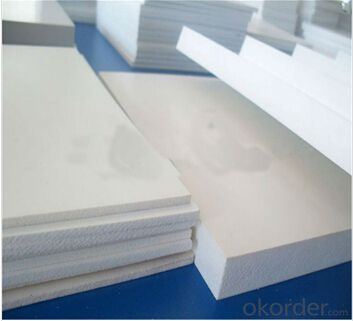

plastic sheet extrusion machine production line , pvc board production line , pvc decoration sheet production line:

PVC/WPC Free Foamed Sheet Production Line

Professional manufacture with more than 10 years experience.

High output , low consumption

plastic sheet extrusion machine production line , pvc board production line , pvc decoration sheet production line:

The plastic plate and sheet extrusion line is specially designed for the extrusion of single layer or multi-layer plate and sheef of PC or PMMA. It is also suitable for the sheet extrusion of PE , PP, PS, ABS and other materials.

The international famous components, combined with decades of year’s experience in the plastic machinery industry, make the whole production line more perfect, reliable and steady.

Product Technical Parameters:

model | cmax120/21 | cmax80/156-1220 |

products width(mm) | 1400 | 1220 |

| products thickness | 0.3-1.5 | 0.5-3 |

extruder specification | cmax120/21 | cmax80/156 |

Main motor power(KW) | 90 | 75 |

| Designed extrusion output(KG/H) | 350 | 300 |

Our service:

- Q: Basic parameters of extruder screw

- 2. The ratio of the length to diameter of the screw, the length of the screw L/Ds and the ratio of L to the diameter of the screw Ds is called the ratio of length to diameter. When the other conditions are constant (such as the diameter of the screw), increasing the ratio of length to diameter means increasing the length of the screw. The L/Ds value is large and the temperature distribution is reasonable, which is beneficial to the mixing and plasticizing of plastics. At the same time, the heating time of the plastic in the barrel is longer, and the plasticization of the plastic will be sufficient and more uniform. So as to improve the quality of machine plastics. If the plastic quality requirement is constant, the rotation speed of the screw can be increased after the ratio of length to diameter increases, thereby increasing the extrusion amount of the plastic. However, too large length diameter ratio, power consumption will increase the screw, and the screw and barrel of the processing and assembly of chicken more difficult; the possibility of screw bending will increase, will cause the abrasion of the screw and the inner wall of the cylinder, reduce the service life. In addition, the heat sensitive plastic, large diameter and long retention time than thermal decomposition, the plasticizing and impact plastic extrusion quality. Therefore, in the full use of the advantages of increasing the ratio of length to diameter, the selection should be based on the physical properties of the processed plastics and the quality requirements of the products.

- Q: producing polyethylene polypropylene fiber, masterbatch in the dark spot under the light, that is, masterbatch does not change, filter replacement frequently, half an hour... 40The equipment is Changzhou Riyue extruding machine, production of polyethylene polypropylene masterbatch, a dark spot in the light, it is not frequent replacement of masterbatch, filter plugging, half an hour, I added the 30% filling masterbatch, how to solve this problem? Other particles are not wet either. Masterbatch is not turned for help

- Is that settled? This technology is not available online! No one wants to say free, need technical contact me!

- Q: What impact does the extruder vacuum pump open or close on the extrusion product?

- If the vacuum pump is opened, the air in the extruded product will be removed and the product material will be more closely packed. If the vacuum pump does not open, it may cause bubbles in the extruded product.

- Q: Cable extrusion machine 6.57090 machine model how to see, know the master to say, thank you

- Screw diameterAskDo you mean the plastic screw? 90 machines are so long. What's the 90 machine? Thank youChasing the answerDiameter, not length

- Q: Produce 10 square wires with the smallest extruder

- If the production of single core line, then 50 machines can also do, but low efficiency, unstable line,.70 or 90 machine idealIf it is a production sheath line, do at least 70 machines, preferably 70 or 90 insulation, and 90/120 as sheath

- Q: What are the two types of extrusion?

- Extrusion? The extruder. The extruder is divided into single screw extruder and twin screw extruder, and the twin screw extruder is divided into two parts: flat, double and cone.

- Q: Can PC and PP be extruded together with two materials in an extruder?

- No co extrusion, PC polycarbonate, PP polypropylene, two kinds of product structure is not the same, not the same chemical composition, viscosity and liquidity is not the same, processing temperature and processing technology is also very different, and two kinds of products, so not incompatible, CO extrusion.

- Q: Extruder price

- According to the size of the screw, single and double screw configuration is different, there are many different prices between fifty thousand to two hundred thousand, we specialize in the production of extruders, crushers and mixing machines, high quality and low price, contact information on the user name

- Q: PLC based extrusion machine control system design graduation thesis and PLC based injection molding machine control system thesis content?

- I can help you with this design.Select the topic according to the academic direction. The key to the value of thesis writing lies in the ability to solve specific problems in a particular industry, especially in academic terms. Therefore, one of the techniques for selecting and refining titles is to select and refine them according to their academic value.

- Q: Why? What is the raw material of plastics? What is the process flow of the process?.

- It must be injection, you see that hole, that button, can not squeeze out.

Send your message to us

pvc/pe/pp extrusion machine acrylic sheet extruding sex film extruder machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords