PE plastic foam sheet extrusion machine line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

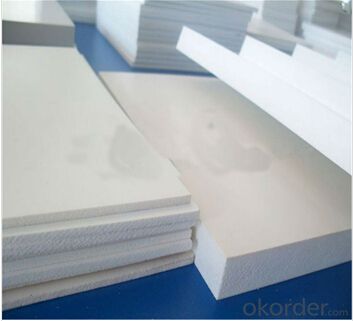

plastic sheet extrusion machine production line , pvc board production line , pvc decoration sheet production line:

PVC/WPC Free Foamed Sheet Production Line

Professional manufacture with more than 10 years experience.

High output , low consumption

plastic sheet extrusion machine production line , pvc board production line , pvc decoration sheet production line

Features:

The plastic plate and sheet extrusion line is specially designed for the extrusion of single layer or multi-layer plate and sheef of PC or PMMA. It is also suitable for the sheet extrusion of PE , PP, PS, ABS and other materials.

The international famous components, combined with decades of year’s experience in the plastic machinery industry, make the whole production line more perfect, reliable and steady.

Product Technical Parameters:

model | CMAX120/21 | CMAX80/156-1220 |

products width(mm) | 1400 | 1220 |

| products thickness | 0.3-1.5 | 0.5-3 |

extruder specification | GWP120/21 | GWC80/156 |

Main motor power(KW) | 90 | 75 |

| Designed extrusion output(KG/H) | 350 | 300 |

Our service:

- Q:extrusion machine prone to coke material, what is the cause? How to improve or solve?

- Is the place where the material is easy to burn rough? Add stabilizers and lubricants appropriately.

- Q:What raw material does the extruder use?

- An extruder in which an air vent is disposed at the center of an exhaust extruder to allow removal of air and volatiles from the processed plastic. The main machine of plastic extruder is plastic extruderIt consists of an extrusion system, a drive system and a heating and cooling system. 1. extrusion system extrusion system includes screw, cylinder extrusion die head, extrusion die head, molding parts of the extruder. Also known as extrusion die, extrusion die.

- Q:Wire and cable extrusion machine extrusion die how to quickly adjust the core degree, how can I touch it by hand?,

- It depends on experience, and the lines made by squeezing it are solid. When you make the line, you can see the expansion and skewness of the material!

- Q:What should be paid attention to in the daily maintenance of the extruder?

- HostCheck the patency of cooling water, temperature (general / 26 C), feeding, cylinder temperature and pressure, friction condition of screw and barrel.NoseThe size loss of the perforated plate, the damage and corrosion of the runner surface, and whether the obstruction occurs affect the appearance and output of the product.

- Q:Which type of inverter is suitable for extruding machine? Please give expert advice, and G series is discontinued

- Proposed Delta VFD-cp Series ~!AskCP2000 is constant pressure water supply... Are you sure you can use it? And C2000 is better than qualifiedChasing the answerWrong number ~ ~ should be C2000, and VE Series ~ ~ these two are suitable, ~~B, CP is not good ~!

- Q:Plastic double screw extruder, pumping air will accumulate material, how is it going on?

- Adjust the assembly and check the exhaust block

- Q:Taper twin screw extrusion machining of plastic masterbatch? What ancillary equipment do you need?

- Can, but need feeding machine and related auxiliary mixing granulator, the cost is not low, but the effect is less than double make flat, because itself is not suitable for the design of double cone, adjustment of the formula is the key.

- Q:Why? What is the raw material of plastics? What is the process flow of the process?.

- 1. injection molding2., the structure is relatively complex, high appearance requirements. Extrusion does not meet requirements3. most are: ABS, ABS+PC, PP and so on4., according to color requirements granulation - drying particles - filling the mold ---- debugging injection molding machine ---- injection molding production - after the selection of finished packaging (if silk screen requirements, but also the need for silk screen)

- Q:Comparison of injection molding machines and Extruders

- Considerations for extruder use:1, extrusion machine is running forward, avoid reverse2, avoid fasting operation, must heat engine feeding operation, so that can avoid sticking bar (holding shaft) phenomenon3, the extruder inlet, vent hole is strictly prohibited access to iron and other miscellaneous, so as not to cause accidents, affect production4, safe use of electricity, grounding wire5. When the machine is running, it is forbidden to touch the rotating parts such as the material inlet, the material outlet, the belt, the gear and so on6, before using the machine should be injected with lubricating oil, so as not to cause damage to the machineSince the extruder as one of the three synthetic plastic material since the advent of rapid development.

- Q:Why can the plastic extrusion machine extrude the flat bar?

- What's the reason for pulling out the stripes?1, the vacuum is not enough.2, high temperature settings.3, formula lubrication is too much

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PE plastic foam sheet extrusion machine line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords