aluminum extrusion process flow chart

aluminum extrusion process flow chart Related Searches

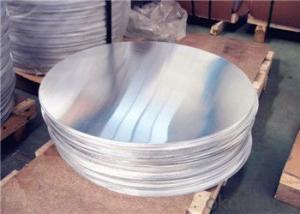

Aluminum Extrusion Shapes Aluminum Extrusion Plate Aluminum Extrusions Aluminium Extrusion Aluminum Extrusion Framing Aluminum Periodic Table Aluminum Plate Thickness Chart Aluminum Extrusions Stock Shapes Cutting Aluminum Sheet Bosch Aluminum Extrusion Aluminum Extrusion Stock Aluminum Extruded Tubing Extruded Aluminum Stock Shapes Aluminum Extrusion Shapes Stock Aluminum Extrusions Stock Forming Aluminum Plate Aluminum Plate Weight Chart Extruded Aluminum Rail Aluminum Tread Plate Sheet Cold Forming Aluminum Aluminum Transition Plate Extruded Aluminum Track Aluminum Tooling Plate Extruded Aluminum Stock Drilling Through Aluminum Plate Aluminum Mending Plate Aluminum Circle Sheet Aluminum Tool Plate 3d Printer Aluminum Build Plate Extruded Aluminum T Slot Platealuminum extrusion process flow chart Supplier & Manufacturer from China

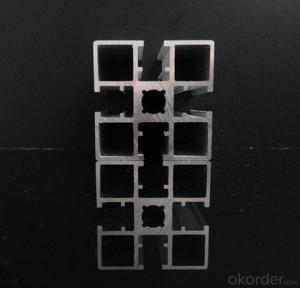

The aluminum extrusion process flow chart encompasses a series of products that are manufactured through the process of extrusion, which involves forcing aluminum material through a die to create various shapes and profiles. These products are widely used in numerous industries, including construction, automotive, aerospace, and consumer goods, due to their lightweight, high strength, and excellent corrosion resistance. The extruded aluminum profiles are utilized in a variety of applications, such as window frames, door frames, structural components, and decorative elements, making them indispensable in both functional and aesthetic aspects of various projects.Aluminum extrusion process flow chart products are known for their versatility and adaptability, catering to the diverse needs of different industries and applications. They are particularly favored for their sustainability, as aluminum is a highly recyclable material, reducing the environmental impact of manufacturing and construction. The usage scenarios for these extruded profiles are vast, ranging from architectural facades and transportation components to electronics enclosures and furniture frames, showcasing their broad utility and appeal.

Okorder.com is recognized as a leading wholesale supplier of aluminum extrusion process flow chart products, boasting a comprehensive inventory that caters to the specific requirements of clients across various sectors. With a commitment to quality and customer satisfaction, Okorder.com ensures that the aluminum extrusion products they supply meet the highest industry standards, providing customers with reliable and durable solutions for their projects.

Hot Products