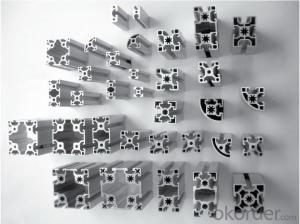

Japanese Architectural Aluminum Extrusion Profiles

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft, durable, lightweight, ductileand malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible lightand an excellent reflector (as much as 98%) of medium and far infraredradiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the densityand stiffness of steel. It is easily machined,cast, drawn and extruded.

Features:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

- Q: Knowledge of aluminum profile warehouse management (detail)

- Warehouse management is the main task required under the factories and production equipment condition of overall planning, rational layout; to strengthen the internal economic responsibility system, scientific division, forming material export management guarantee system; business must implement the work quality standardization, application of modern management technology and the ABC classification method, and constantly improve the level of warehouse management. The main work is material inspection, income, inventory, storage and custody of materials, materials delivery, billing statements, etc.

- Q: This question asks if aluminum profiles can be utilized in cold weather conditions and seeks an explanation for their suitability.

- <p>Yes, aluminum profiles can be used in cold climates. Aluminum is a lightweight and durable material that maintains its strength and structural integrity even in extreme low temperatures. It does not rust or corrode, which makes it ideal for use in environments with harsh weather conditions. Additionally, aluminum has good thermal conductivity, which allows it to dissipate heat effectively, but it also has low thermal expansion, meaning it does not expand or contract significantly with temperature changes. This characteristic helps prevent warping or cracking in cold climates. Properly designed and installed aluminum profiles can withstand the challenges of cold weather without compromising their performance or longevity.</p>

- Q: This question asks about the variety of dimensions and forms that aluminum profiles can come in.

- <p>Aluminum profiles are available in a wide range of sizes and shapes to suit various applications. Common shapes include rectangular, square, circular, and special profiles like angles, channels, and tees. Sizes can vary from thin strips to thick bars, with specific dimensions tailored to the needs of the project. The profiles can be flat, hollow, or have complex cross-sectional geometries. They are also available in different surface finishes, such as anodized, painted, or powder-coated, to enhance their appearance and durability. The selection of aluminum profiles depends on the structural requirements, design specifications, and the industry they are intended for, such as construction, automotive, or aerospace.</p>

- Q: Are aluminum profiles suitable for use in automotive suspension systems?

- Indeed, automotive suspension systems can benefit from the use of aluminum profiles. Aluminum, being both lightweight and strong, offers numerous advantages in suspension design. To begin with, the lightweight properties of aluminum profiles contribute to reducing the overall weight of the suspension system. This not only improves fuel efficiency but also enhances the vehicle's performance and handling. The decreased weight allows for faster acceleration, improved braking, and enhanced maneuverability. Moreover, aluminum profiles possess an exceptional strength-to-weight ratio, enabling them to withstand high loads and stresses while remaining lightweight. This makes them ideal for handling the dynamic loads experienced by suspension systems, such as bumps, vibrations, and impacts. Aluminum profiles can effectively absorb and distribute these loads, ensuring a smooth and comfortable ride for the vehicle occupants. Additionally, aluminum is highly resistant to corrosion, which is of utmost importance in automotive applications. Given that suspension systems are exposed to various environmental conditions, including moisture, salt, and road debris, the use of aluminum profiles minimizes the risk of corrosion. This, in turn, enhances the durability and longevity of the suspension components. Furthermore, aluminum profiles offer great versatility and can be easily shaped and formed into complex geometries required for suspension system components. This allows for greater design flexibility and optimization of performance. Aluminum profiles can be utilized in the manufacturing of various suspension components, including control arms, knuckles, and subframes. In conclusion, aluminum profiles are unquestionably suitable for use in automotive suspension systems. Their lightweight nature, high strength-to-weight ratio, corrosion resistance, and design flexibility make them an excellent choice for maximizing the performance, efficiency, and durability of suspension systems in vehicles.

- Q: What are the different surface polishing options for aluminum profiles?

- Aluminum profiles offer various surface polishing options, each with its own shine and finish levels. These methods include mechanical polishing, chemical polishing, electrolytic polishing, and anodizing. Mechanical polishing involves using abrasives and polishing compounds to physically eliminate surface imperfections and achieve a smooth, reflective finish. This can be done manually or with automated machines. While it provides a high shine, it requires careful attention to detail and multiple steps. Chemical polishing, on the other hand, employs chemical solutions to dissolve a thin layer of aluminum, resulting in a smoother surface. It is often used for large-scale production due to its quick and uniform application, but it may not offer the same level of shine as mechanical polishing. Electrolytic polishing utilizes an electric current to eliminate surface imperfections and create a polished finish. By using the aluminum profile as an anode and a conductive material as the cathode, electrolytic polishing produces a mirror-like finish with excellent precision and uniformity. Although not a polishing method itself, anodizing is a commonly used surface treatment for aluminum profiles. It involves creating a protective oxide layer on the metal's surface through an electrochemical process. Anodizing enhances the appearance of profiles by providing a smooth, colored, or clear finish, while also improving their durability and resistance to corrosion. The choice of surface polishing option depends on factors such as the desired shine level, the complexity of the profile's design, and the intended application. It is essential to consider cost, time, and quality requirements when selecting the most suitable option, as each method has its advantages and limitations.

- Q: Can aluminum profiles be used in display stand and podium manufacturing?

- Yes, aluminum profiles can definitely be used in display stand and podium manufacturing. Aluminum is a versatile and durable material that offers many benefits for these applications. Aluminum profiles are lightweight yet strong, making them ideal for creating portable and sturdy display stands and podiums. They can be easily customized and fabricated to meet specific design requirements, allowing for flexibility in creating unique and eye-catching display stands and podiums. Additionally, aluminum profiles have excellent corrosion resistance, which ensures that the displays and podiums will look good and last for a long time, even in outdoor or high-traffic environments. Overall, using aluminum profiles in display stand and podium manufacturing is a smart choice due to their versatility, strength, and durability.

- Q: This question asks for an overview of the various types of connectors that are used to join aluminum profiles in construction or assembly.

- <p>Aluminum profiles are joined together using several types of connectors, each serving specific purposes in assembly. Common types include: 1. T-slots and T-nuts, which provide a secure and adjustable connection. 2. Corner brackets, used to join profiles at right angles. 3. Angle connectors, for joining profiles at various angles. 4. End caps, used to cover the ends of profiles. 5. Clamps and brackets, for securing profiles in place. 6. Hinges, allowing for pivoting connections. 7. Cylindrical connectors, for joining round profiles. 8. Specialized connectors for specific applications, such as cable management or modular systems. These connectors are crucial for creating robust, modular structures in various industries.</p>

- Q: Can aluminum be utilized as a material for constructing railings and fences?

- <p>Yes, aluminum profiles are commonly used for railings and fences due to their durability, low maintenance, and resistance to corrosion. They are lightweight, easy to install, and can be powder-coated in various colors to match architectural styles. Aluminum railings and fences are also appreciated for their strength and ability to withstand harsh weather conditions without rusting or rotting, making them a popular choice for both residential and commercial applications.</p>

- Q: Can aluminum profiles be used in the manufacturing of furniture?

- Yes, aluminum profiles can be used in the manufacturing of furniture. Aluminum is a versatile and lightweight material that offers several advantages for furniture production. It is highly durable, resistant to corrosion, and has a high strength-to-weight ratio. These properties make it suitable for various furniture applications, including chairs, tables, shelving units, and frames. Additionally, aluminum profiles can be easily customized, allowing for the creation of unique and modern designs. The use of aluminum in furniture manufacturing also contributes to sustainability, as it is a recyclable material. Overall, aluminum profiles provide designers and manufacturers with flexibility and durability, making them a popular choice in the furniture industry.

- Q: What are the different types of fasteners used for aluminum profiles?

- There are several types of fasteners that are commonly used for aluminum profiles: 1. T-slot nuts: T-slot nuts are designed to fit into the T-slot grooves of aluminum profiles. They have a threaded hole that allows for the attachment of bolts, screws, or other fasteners. 2. Bolts and screws: Bolts and screws are used to secure aluminum profiles together or to other components. They come in a variety of lengths and sizes to accommodate different applications. 3. Corner brackets: Corner brackets are used to create strong joints between aluminum profiles at right angles. They typically have holes for screws or bolts, allowing for easy attachment. 4. T-bolts: T-bolts are similar to regular bolts, but they have a T-shaped head that fits into the T-slot grooves of aluminum profiles. This allows for quick and secure attachment without the need for nuts or additional hardware. 5. Angle brackets: Angle brackets are used to create joints between aluminum profiles at different angles. They typically have holes for screws or bolts, making it easy to secure the profiles together. 6. Clamps: Clamps are used to hold aluminum profiles in place or to attach them to other components. They come in various designs, such as lever clamps or eccentric clamps, and can be easily adjusted and tightened for a secure fit. 7. End caps: End caps are used to cover the ends of aluminum profiles, providing a finished look and protecting the profile from debris or damage. These are just a few examples of the different types of fasteners used for aluminum profiles. The choice of fastener will depend on the specific application and the desired level of strength and versatility.

Send your message to us

Japanese Architectural Aluminum Extrusion Profiles

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords