Aluminum Extrusion Profiles Illinois - Electrophoresis Aluminium Profile 6003 Quality

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

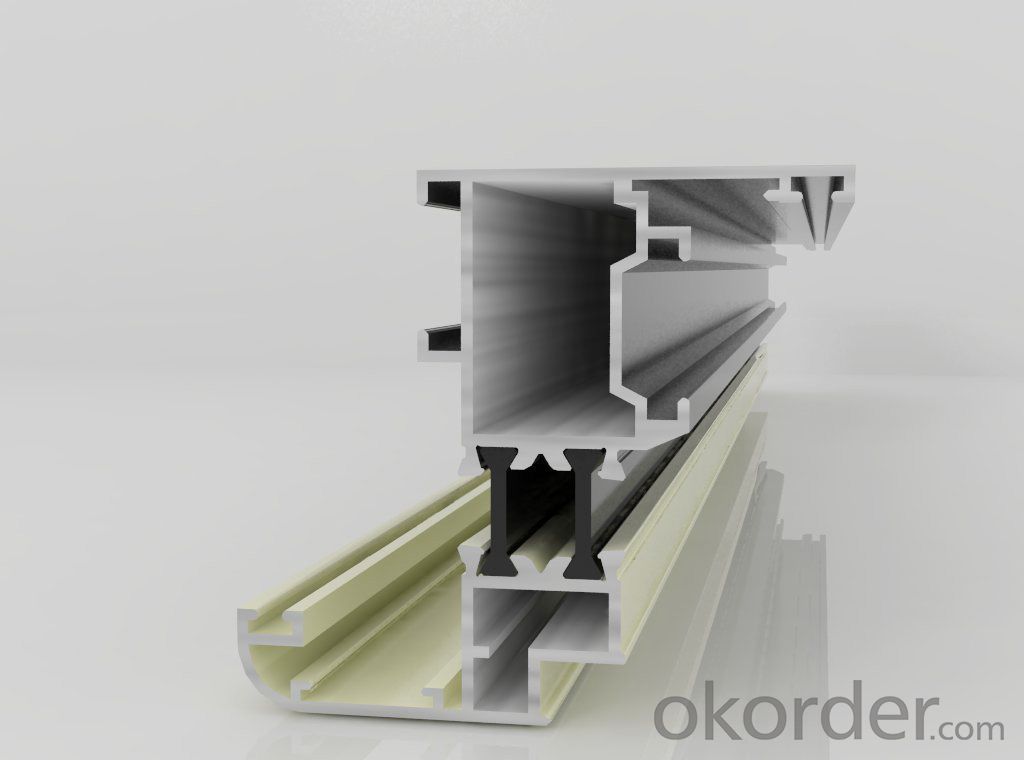

1.Structure of Electrophoresis Aluminium Profile 6003 Quality Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Electrophoresis Aluminium Profile 6003 Quality:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

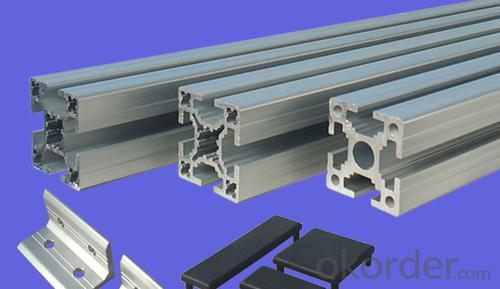

3.Electrophoresis Aluminium Profile 6003 Quality Images:

4.Aluminium Profile for Cars Auto-parts Good Quality Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Are aluminum profiles recyclable and can they be used again in flooring applications?

- <p>Yes, aluminum profiles can be recycled and reused in flooring applications. Aluminum is a highly recyclable material, with recycling processes that retain its properties without loss in quality. This makes it an environmentally friendly choice for flooring as it reduces waste and conserves resources. Recycled aluminum can be used to create new profiles for flooring systems, maintaining strength and durability while offering a sustainable solution.</p>

- Q: Aluminum profile 606360056061, T5 and T6 hardness GB, how much?

- Generally divided into Vivtorinox hardness, Rockwell hardness and Vickers hardness and webster hardness. Our enterprises are generally in accordance with webster hardness test, GB 6063-T5 8HW 6063-T6 11.5HW6005-T5 15HW 6005-T6 15HW6061-T5 15HW 6061-T6 15HWIf you need other hardness units, you can refer to the conversion

- Q: This question asks for methods to avoid corrosion on aluminum profiles during the installation process.

- <p>To prevent corrosion on aluminum profiles during installation, follow these steps: Use high-quality aluminum that has a protective oxide layer. Ensure the installation environment is dry and clean. Avoid contact with corrosive substances like acids or alkalis. Apply a protective coating or sealant if the profiles will be exposed to harsh environments. Use stainless steel or corrosion-resistant fasteners. Regularly inspect and clean the profiles to remove any dirt or debris that could lead to corrosion. Proper installation techniques and maintenance can significantly reduce the risk of corrosion on aluminum profiles.</p>

- Q: This question asks about the various types of aluminum profiles that are utilized specifically for constructing wall frames.

- <p>Aluminum profiles for wall frames come in various types, each serving specific purposes. Common types include: 1) Structural profiles, which provide the main support and strength to the frame; 2) Cover profiles, used to conceal joints and fasteners, enhancing the aesthetic appeal; 3) Insulation profiles, designed to provide thermal insulation; 4) Glazing profiles, used to hold glass or other transparent materials in place; 5) Corner profiles, for joining two walls at a right angle; 6) Sealing profiles, to ensure weatherproofing and airtightness; and 7) Special profiles, tailored for unique architectural designs or specific functions. Each type is chosen based on the structural requirements, design aesthetics, and performance needs of the wall system.</p>

- Q: Is it possible to recycle aluminum profiles repeatedly without a substantial loss in their quality or functionality?

- <p>Yes, aluminum profiles can be recycled multiple times without significant degradation in performance. Aluminum is highly recyclable, and the recycling process does not compromise its properties. In fact, recycled aluminum maintains the same strength, durability, and malleability as new aluminum. This makes it an environmentally friendly material, as it reduces the need for mining new aluminum and conserves resources.</p>

- Q: Can aluminum profiles be used in the construction of exhibition booths?

- Yes, aluminum profiles can be used in the construction of exhibition booths. Aluminum profiles are lightweight, durable, and versatile, making them an ideal choice for constructing modular exhibition booths. These profiles can be easily assembled and disassembled, allowing for easy transportation and reconfiguration of the booth layout. Additionally, aluminum profiles offer a sleek and modern aesthetic, providing a professional and visually appealing display for exhibitors. They can be used to create frames, partitions, shelving, signage, and various other components required for exhibition booths. Overall, aluminum profiles offer a cost-effective and efficient solution for constructing exhibition booths.

- Q: Are aluminum profiles suitable for exhibition displays?

- Yes, aluminum profiles are suitable for exhibition displays. Aluminum is a lightweight and durable material, making it ideal for creating modular structures that can be easily transported and assembled at different exhibition venues. These profiles can be used to construct display walls, stands, booths, and other exhibition components. One of the main advantages of using aluminum profiles for exhibition displays is their versatility. They can be easily customized and adapted to meet specific design requirements, allowing for the creation of unique and eye-catching displays. Additionally, aluminum profiles can be easily connected and disassembled, making them a practical choice for exhibitions that require frequent setup and teardown. Another benefit of using aluminum profiles for exhibition displays is their aesthetic appeal. Aluminum has a sleek and modern look that can enhance the overall visual impact of the exhibition. It can be finished with various coatings or colors to match the branding or theme of the event, further enhancing the overall presentation. Furthermore, aluminum profiles offer great stability and strength, ensuring that exhibition displays can withstand the rigors of a busy exhibition environment. They are also resistant to corrosion, which is important when considering the longevity and durability of the display. In summary, aluminum profiles are a suitable choice for exhibition displays due to their lightweight, durability, versatility, aesthetic appeal, and strength. They provide the necessary stability and can be easily customized to create visually appealing and functional exhibition displays.

- Q: How do aluminum profiles perform in electrical insulation applications?

- Aluminum profiles do not perform well in electrical insulation applications as aluminum is a good conductor of electricity. It is not suitable for providing insulation and can potentially pose a risk of electrical conductivity.

- Q: What are the different installation methods for aluminum profiles?

- There are several installation methods for aluminum profiles, including surface mounting, recessed mounting, and corner mounting. Surface mounting involves attaching the profile directly onto a flat surface using screws or adhesive. Recessed mounting involves embedding the profile into a groove or channel in a surface, creating a sleek and seamless appearance. Corner mounting is used to join two profiles at a 90-degree angle, typically using brackets or connectors. Each method offers different aesthetic and functional benefits, allowing for versatile installation options.

- Q: Can aluminum profiles be used for soundproofing?

- Yes, aluminum profiles can be used for soundproofing to a certain extent. Aluminum profiles are commonly used in the construction industry for various purposes, including window frames and door frames. When used in soundproofing applications, aluminum profiles can help reduce noise transmission through windows and doors. Aluminum is a lightweight and durable material that can effectively block or dampen sound waves. It has good structural integrity, which allows for the creation of tight seals when installed properly. This helps in reducing sound leakage and improving sound insulation. To enhance soundproofing, aluminum profiles can be combined with other materials like rubber gaskets or weatherstripping, which further improves the sealing properties. Additionally, double or triple glazing with laminated glass can also be used in conjunction with aluminum profiles to provide better sound insulation. However, it is important to note that while aluminum profiles can contribute to soundproofing, they may not provide the same level of sound reduction as other specialized soundproofing materials such as acoustic panels or insulation. The effectiveness of aluminum profiles in soundproofing also depends on factors such as the thickness and quality of the profiles, the design of the window or door system, and the overall construction of the building. In conclusion, while aluminum profiles can help in reducing noise transmission through windows and doors, they should be considered as part of a comprehensive soundproofing strategy rather than the sole solution.

Send your message to us

Aluminum Extrusion Profiles Illinois - Electrophoresis Aluminium Profile 6003 Quality

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords