Aluminum Pipes - Aluminium Profile AA6063

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1 Specifications of Aluminum Profiles 6063-T5

Alloy Number | 6063 6061 6060 and different aluminium alloy |

Temper | T4 T5 T6 or other special status |

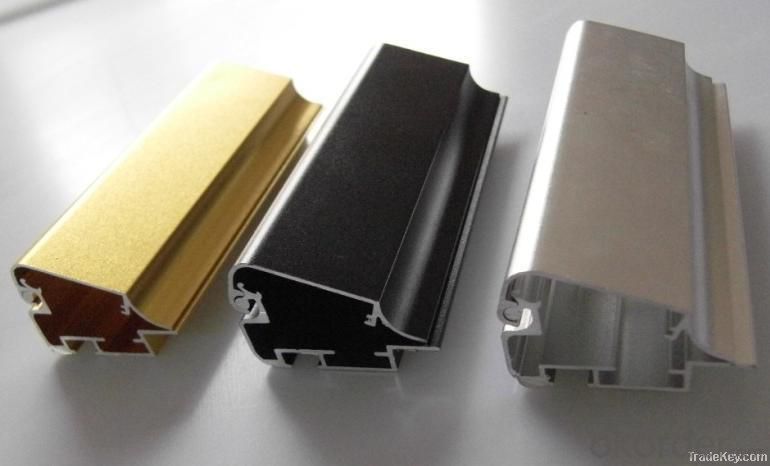

Surface available | Mill finish, Anodized, Powder Coating, Wooden transfering, electrophoresis, heat insulation, PVDF, and deep processing |

Thickness: | >0.8mm |

Width: | <300mm |

Standard | GB5237.1-2008 |

Special Specification is available on customer’s requirement

2 Usage/Applications of Aluminum Profiles 6063-T5

Aluminium Profiles are widely used in construction(windows & doors,curtain wall), decoration ( flooring and tiling, kitchen) and industry ( heat sink ).

CNBM produces aluminum profiles which meets the national standard GB5237.1-2008. Our strong quality control term bring you the most-qualified products. And with state-of-the-art equipment, and the state owned company background, we have to say, you will understand why there are so many company choose CNBM to be their supplier.

- Q: Are aluminum pipes suitable for automotive applications?

- Automotive applications can benefit from the use of aluminum pipes. The suitability of aluminum pipes in automotive use is undeniable. To begin with, the lightweight nature of aluminum contributes to the reduction of the vehicle's overall weight. Consequently, this leads to enhanced fuel efficiency and performance. Moreover, aluminum pipes possess remarkable resistance to corrosion, rendering them ideal for automotive applications that frequently encounter moisture, road salt, and other corrosive elements. Additionally, the impressive thermal conductivity of aluminum pipes allows for efficient dissipation of heat in automotive cooling systems. Lastly, the versatility of aluminum pipes enables easy fabrication and shaping into various sizes and forms, making them adaptable for different automotive applications. In conclusion, the integration of aluminum pipes in automotive applications can result in improved durability, fuel efficiency, and performance.

- Q: Maintenance personnel, Hisense inverter air conditioning with copper or aluminum tube?

- Aluminum recommended not to buy Hisense's refrigeration is not good

- Q: One aluminum products, T6 hardness is not up to the requirements of heat treatment, the manufacturers say that is the low magnesium content, not between 0.8~1.2 (the actual measurement is 0.70~0.81 content), there is relationship between content and heat treatment on the quality of magnesium?

- If a certain amount of manganese and chromium, can neutralize the bad effect of iron; sometimes add a small amount of copper or zinc, to improve the strength of the alloy, and the corrosion resistance decreased significantly; there is a small amount of copper conductive materials, titanium and iron to offset the adverse effects on the conductivity of the zirconium; or titanium can refine the grain and control of recrystallization; in order to improve the cutting performance, adding lead and bismuth. In Mg2Si solution in aluminum, the alloy has artificial aging hardening function. The main alloy elements in 6061 aluminum alloy are magnesium and silicon, which have moderate strength, good corrosion resistance, weldability and good oxidation effect.

- Q: What are the different pressure ratings available for aluminum pipes?

- The pressure ratings for aluminum pipes can vary depending on the specific type and size of the pipe. However, commonly available pressure ratings for aluminum pipes range from 150 psi (pounds per square inch) to 300 psi.

- Q: 1100 what is the difference between the aluminum tube and the 6063 material aluminum tube, please advise

- The 1100 is rust proof aluminum grades, good corrosion resistance, good plasticity, but the intensity is the lowest, 6063 forging Aluminum Alloy, is Aluminum Alloy, if after solid solution treatment and aging, high strength and hardness, but the corrosion resistance of less than 1100,

- Q: How can the aluminum tube bending be processed and how to make manual bending equipment?

- How to make manual bending equipment?A guide wheel is additionally provided with a lever to apply the rod to rotate the force in the center of the guiding wheel.

- Q: How many kilograms does the copper pipe withstand? How many kilograms does the aluminum pipe withstand?

- The allowable stress for TP2 copper tubes is specified as S=41.2MPa (6000Psi).The allowable stress of aluminum pipe should be checked

- Q: The aluminum pipe in the fridge is leaking. What should I do to fill it up?

- With good brothers gluing, 1; polished by voile. 2; with good brothers glued on the line, remember a few times glue.

- Q: Can aluminum pipes be used for gas transportation?

- Yes, aluminum pipes can be used for gas transportation. Aluminum is a lightweight and corrosion-resistant material, making it suitable for safely transporting various gases.

- Q: What are the different joining methods for aluminum pipes?

- Aluminum pipes can be joined using various methods, each having its own benefits and applications. 1. Welding, the most common method, involves melting the pipe edges and fusing them together with heat and a filler material. TIG and MIG welding are commonly used for aluminum pipes but require skilled labor and specialized equipment. 2. Mechanical joining techniques include flanging, threading, and compression fittings. Flanging involves creating a flange on the pipe end and connecting it to another flange using bolts or screws. Threading involves cutting threads on the pipe ends and using threaded connectors. Compression fittings tightly clamp the pipes together using a compression nut and ferrule. These methods are easy to perform and do not require welding, making them suitable for specific applications. 3. Brazing uses a lower melting point filler material, typically a brass alloy, to bond aluminum pipes. The filler material is heated until it melts and flows into the joint, creating a strong bond. Precise temperature control and flux are necessary for proper bonding. 4. Adhesive bonding employs specialized adhesive or epoxy to bond aluminum pipes. The adhesive is applied to the joint, and the pipes are pressed together and left to cure. Although adhesive bonding provides a strong and lightweight joint, it may not be appropriate for high-temperature applications. The choice of joining method depends on factors such as the application, required strength, cost, and availability of equipment or expertise. It is crucial to consider these factors carefully and seek advice from experts to determine the most suitable joining method for aluminum pipes in a specific situation.

Send your message to us

Aluminum Pipes - Aluminium Profile AA6063

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches