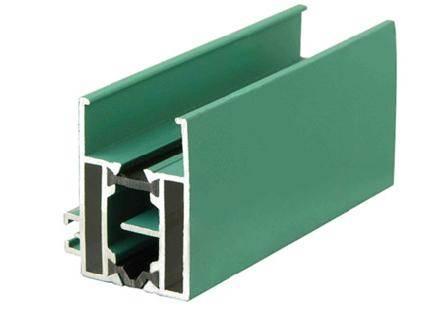

Aluminum Windows Profiles - Heat Insulation Aluminium Profile AA6063

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Powder Coating Aluminum door profile of - AA6060

1) Material : 6063 6061 6060 and different aluminium alloy

2) Alloy Temper: T4 T5 T6 or other special status as per customer's needing.

3) Optional Surface treatment: mill finish, anodized sliver ,anodized bronze, anodized champagne, anodized black pearl, various power coating color, electrophoretic sliver, electrophoretic champagne, electrophoretic golden,

electrophoretic titanium, machine polish sliver, machine polish bronze, wooden grain color, and Fluorocarbon spraying.

4) Annual capacity : 120000TON

5) Quality : China Nation Standard GB/T 5237 2004 (advanced class)

6) Application: can be widely used for aluminium window, door, curtain wall, hand railing ,

normal aluminium profiles, decoration and industrial aluminium profiles.

7) Advantage: Famous Brand reasonable&market price, soonest delivery and good after sale- service

- Q: You need is the extrusion machine section now has Liaoning Zhong Wang Liaoyuan Midas Nanshan aluminum aluminum Hunan Sheng Guangxi jungle SWA South northeast light alloy etc. they have more than 4500 tons of extrusion machine mainly produces large section comprises a track body profile LED lamp shell container ship with large cross section conductor rail section I is a seamless tube a market analyst if you have aluminum industrial material need to be aware of the problem you can consult me as friends.

- Our company has several 1100 ton extruders, but I feel all right

- Q: What are the different finishing options available for aluminum profiles?

- To enhance the appearance and provide extra protection, aluminum profiles offer a range of finishing options. These options can be divided into two main categories: surface treatments and coatings. Surface treatments encompass anodizing, powder coating, and polishing. Anodizing, a widely used technique, involves creating a durable and corrosion-resistant layer on the aluminum surface through an electrochemical process. This method offers various colors and finishes while preserving the metallic look. Powder coating, on the other hand, entails applying a dry powder to the aluminum surface and then curing it with heat, resulting in a smooth and long-lasting finish. For a reflective and glossy appearance, polishing is an alternative that involves mechanically smoothing the aluminum surface. Coatings, however, involve the application of a protective layer on the aluminum. These coatings can be either organic or inorganic. Organic coatings, such as paint or lacquer, provide a decorative finish and safeguard the surface against scratches and oxidation. In contrast, inorganic coatings like ceramic or enamel offer superior durability and resistance to abrasion, heat, and chemicals. Furthermore, mechanical finishing processes like brushing or sandblasting can be applied to aluminum profiles. Brushing creates a textured finish by using abrasive brushes to form a pattern on the surface. Sandblasting, on the other hand, roughens the surface by forcefully propelling fine particles at high speed, resulting in a matte appearance. Choosing the appropriate finishing option for aluminum profiles depends on factors such as the intended application, aesthetic preference, and desired level of protection. Each option has its own advantages and disadvantages, so it is crucial to consider factors like durability, maintenance, and cost before making a selection.

- Q: I want to make my aluminum oxide, how much money is needed is a set of equipment? Please leave, thank you!

- Aluminum oxide brand and aluminum panel process and process, please

- Q: This question asks for a list of various types of coatings applied to aluminum profiles to prevent corrosion.

- <p>Aluminum profiles are protected from corrosion through several types of coatings. These include: Anodizing, which forms a protective oxide layer; Powder Coating, a durable and weather-resistant finish; Electrophoretic Deposition (E-coat), offering a smooth, corrosion-resistant surface; Fluoropolymer coatings, known for their exceptional chemical resistance and UV stability; and Thermal Spray Coatings, which provide a hard, wear-resistant surface. Each method serves to enhance the aluminum's resistance to environmental factors and extend its lifespan.</p>

- Q: This question asks for methods to guarantee the high quality of aluminum profiles used in a construction project.

- <p>To ensure high-quality aluminum profiles for your building project, start by selecting profiles from reputable manufacturers known for quality. Check for certifications such as ISO 9001 for quality management systems. Inspect the profiles for uniformity in thickness and color, and ensure they are free from defects like dents or scratches. Request third-party test reports to verify the strength and durability of the profiles. Additionally, consider the chemical composition and alloy type to ensure they meet the required specifications for your project. Always procure from suppliers who offer warranties and after-sales support.</p>

- Q: This question asks for the correct procedure to install aluminum profiles.

- <p>To install aluminum profiles correctly, follow these steps: 1. Measure and mark the positions where the profiles will be installed. 2. Clean the surfaces to ensure proper adhesion. 3. Use a suitable adhesive or mechanical fasteners recommended for aluminum. 4. Align the profile with the marked positions and secure it in place. 5. Check for level and plumb, and adjust as needed. 6. Wipe away any excess adhesive and clean the profile. 7. Allow the adhesive to cure according to the manufacturer's instructions. 8. Inspect the installation for any gaps or misalignments and make corrections if necessary. Always refer to the specific installation guidelines provided by the aluminum profile manufacturer for best results.</p>

- Q: How is the price of aluminum profile calculated?

- Aluminum prices are generally in accordance with the aluminum ingot price plus processing fees to count. The aluminum market is unstable compared with other industries, especially the price is changing almost every day. Please take the same day price. Shandong Southwest Aluminum material

- Q: What's the difference between aluminum oxide and electrophoresis?

- Main features: 1 aluminum oxide) has strong abrasion resistance, weatherability and corrosion resistance. 2) can form a variety of colors on the surface of the substrate, the maximum for your requirements. 3) hardness, making it suitable for all kinds of buildings, industrial materials.Main features: 1 electrophoresis aluminum) has strong film hardness and strong impact resistance. 2) has very high adhesion of film, aging is not easy to fall off. 3) has better wear resistance, weather resistance and alkali resistance than aluminum oxide. 4) surface color is rich, beautiful, with a mirror like luster effect.Aluminum electrophoresis processing in oxidized aluminum on the basis of better quality than the oxidized aluminum chip. The price is a little better.

- Q: What are the environmental effects of utilizing aluminum profiles in the construction industry?

- <p>Yes, there are environmental impacts associated with using aluminum profiles in construction. Aluminum production is energy-intensive, which contributes to greenhouse gas emissions. However, aluminum is recyclable, and its recycling process requires significantly less energy than primary production, reducing environmental impact. Additionally, aluminum profiles are lightweight, which can reduce transportation emissions. Despite these benefits, concerns remain about the energy used in aluminum production and the potential for leaching of aluminum into the environment, which can affect soil and water quality.</p>

- Q: What kind of equipment are needed for the production of aluminum profiles?

- The production of aluminum equipment not hundreds of several decades, from the beginning, homogeneous casting furnace, extrusion machine, anodic electrophoretic coating production line groove, powder powder production line, fluorocarbon paint production line, insulated aluminum production line, processing workshop welding riveting, stitching and other processing equipment. Plus to die do I still have, cars, milling, grinding, drilling, EDM, wire cutting, and other processing equipment. I am now in a small department work of aluminum processing company.

Send your message to us

Aluminum Windows Profiles - Heat Insulation Aluminium Profile AA6063

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords