Delmar Company Aluminium Profiles for Ship Mast

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

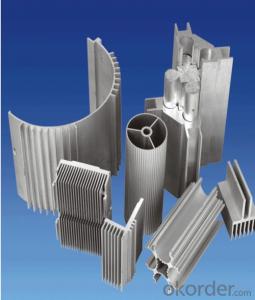

Aluminium Profiles for ship mast

1. Usage:Aluminium Profiles for ship mast

2. Surface: Mill surface treatment

3. Alloy:6082T6 alloy temper

4. Size:various dimensions to meet customer’s requirement

5. Advantage:

The alloy temper of this ship mast is nonheat treatment strengthened alloy which has medium level hardness, good corrosion resistance and weldability. In the atmosphere of sea ocean water, such alloy not only has excellent performance of the general corrosion resistance, and also can eliminate spalling corrosion and inter-granular corrosion.

6. Package:Two pcs of profiles interleaving inserted together to be a couple, ten pcs of profiles wrapped tightly in one bundle.

7. Life time: Last for 50 years

8. Standard: EN755-9 standard

- Q: Request recommended professional aluminum manufacturer?

- Jing Long aluminum, aluminum strip and aluminum wafer production capacity of 60000 tons, this piece in Shangqiu, still have the strength, is a professional production and processing, wholesale distribution of aluminum, hot-rolled plate, hot rolled plate, aluminum plate, aluminum plate, roll spindle is the main.

- Q: Can someone give me a direction? Thank you

- Look where you are and where you are. There are various directions for development, such as bags and so on, bathroom..

- Q: What are the different types of surface protection for aluminum profiles?

- There are several different types of surface protection options available for aluminum profiles. These options are designed to enhance the durability and aesthetics of the aluminum profiles and provide protection against various environmental factors. 1. Anodizing: Anodizing is one of the most common methods of surface protection for aluminum profiles. It involves creating a protective oxide layer on the surface of the aluminum through an electrochemical process. Anodizing provides excellent corrosion resistance and can be done in various colors. 2. Powder Coating: Powder coating involves applying a dry powder to the surface of the aluminum profiles, which is then cured under heat to form a protective layer. Powder coating offers a wide range of color options, excellent durability, and resistance to scratching, chipping, and fading. 3. Paint: Painting is another option for surface protection of aluminum profiles. It involves applying a liquid paint coating to the surface, which provides both protection and aesthetic enhancement. Paint can be customized in terms of color, texture, and finish, but it may not be as durable as other options. 4. Clear Coating: Clear coating is a transparent protective layer that can be applied to aluminum profiles. It provides a glossy finish while preserving the natural appearance of the aluminum. Clear coating offers protection against corrosion, UV radiation, and other environmental factors. 5. Cladding: Cladding involves covering the aluminum profiles with another material, such as stainless steel or composite panels. This provides additional protection against corrosion and wear, while also adding aesthetic appeal and design versatility. 6. Film/Protective Tape: Applying a temporary film or protective tape to the surface of aluminum profiles can provide short-term protection during transportation, installation, or construction. These films or tapes can be easily removed after use, leaving the aluminum profile intact. Each of these surface protection options has its own advantages and disadvantages, and the choice depends on the specific requirements of the application, desired aesthetics, budget, and expected environmental conditions.

- Q: Are there any limitations or drawbacks to using aluminum profiles?

- Yes, there are some limitations and drawbacks to using aluminum profiles. Firstly, aluminum is a relatively soft metal compared to steel, which means it may not be as strong or durable in certain applications. Additionally, aluminum profiles can be more expensive than other materials such as wood or plastic. They also have lower resistance to high temperatures, which can lead to warping or deformation. Finally, aluminum profiles may require additional surface treatments or coatings to protect against corrosion in certain environments.

- Q: What are the industries that require aluminum profiles in industry?

- 1, transportation (including automobile manufacturing, rail transportation).2 equipment and machinery manufacturing.3) durable consumer goods (including light industries).4, transportation, equipment and machinery and equipment manufacturing, durable consumer goods industry, respectively, in China's aluminum profile applications accounted for about 10%, 10% and 12%. While in Europe, North America and Japan aluminum consumption structure, industrial consumption ratio reached 60%, 55% and 40%, much higher than in China. It is expected in the next 5~10 years, China's consumption of aluminum industry will continue to grow in the aluminum products in the proportion of about 30% up to 2015 about 45~50%.5, aluminum plating process, which belongs to the coating technology it is pre plating and electroplating process steps to increase on the basis of conventional Ti process, aluminum is the process of the aqueous solution of salt and hydrochloric acid in the plating after activation of chemical treatment; electroplating bath composition including sulfur acid nickel, nickel chloride, boric acid twelve, sodium lauryl sulfate, saccharin, brightener, this process has the advantages of simple, practical and good effect, the titanium aluminum prepared by the hardness of the film is HV 1500, under the same conditions than the 22 carat gold plating wear 150 times, can be processed into various forms, golden color, black and bright various series of aluminum products.

- Q: Light aluminum is what mean?

- Extruded out only through aging treatment, without other surface treatment of aluminum (such as spraying, oxidation and other deep-processing)

- Q: This question asks about the various materials used to coat aluminum profiles for improving their appearance.

- <p>There are several types of coating materials used on aluminum profiles for aesthetic purposes, including: 1. Powder coating, which offers a durable and colorful finish. 2. Anodizing, a process that enhances the surface hardness and provides a decorative effect. 3. Electrophoretic coating, known for its smooth and even finish. 4. PVDF (Polyvinylidene Fluoride) coating, which is weather-resistant and offers a wide color palette. 5. Thermal spraying, which can provide a decorative or protective layer. 6. Sol-gel coating, a newer technology that offers excellent adhesion and corrosion resistance. These coatings not only enhance the visual appeal but also protect the aluminum from environmental factors and wear.</p>

- Q: Can aluminum profiles be used in outdoor applications?

- Indeed, outdoor applications can make use of aluminum profiles. Aluminum proves to be a versatile and sturdy substance, exhibiting resistance against corrosion and weathering, thus rendering it apt for outdoor purposes. In the realm of construction, aluminum is frequently employed in the creation of outdoor structures such as fences, railings, pergolas, and outdoor furniture. Furthermore, aluminum profiles can undergo treatments involving diverse coatings or finishes to augment their endurance against UV rays, moisture, and other elements of the environment. In conclusion, aluminum profiles provide a dependable and enduring resolution for outdoor applications.

- Q: How do aluminum profiles perform in terms of sound transmission loss?

- Aluminum profiles are known for their excellent sound transmission loss performance. Due to their dense and rigid nature, aluminum profiles effectively block and reduce the transmission of sound waves. The metal's inherent properties, such as high density and low resonance, make it an ideal material for sound insulation applications. Additionally, aluminum profiles can be designed with various shapes and thicknesses to further enhance their soundproofing capabilities. Overall, aluminum profiles offer great sound transmission loss, making them a popular choice for applications where noise reduction is desired, such as in building construction, automotive industry, and HVAC systems.

- Q: Can aluminum profiles be used for stage and event structures?

- Yes, aluminum profiles can be used for stage and event structures. Aluminum is a lightweight and durable material that is widely used in the construction of stage and event structures. It offers excellent strength-to-weight ratio, making it suitable for creating complex and versatile designs while ensuring structural stability. Additionally, aluminum profiles are easy to assemble, disassemble, and transport, making them a popular choice for temporary or portable stage and event structures.

Send your message to us

Delmar Company Aluminium Profiles for Ship Mast

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords