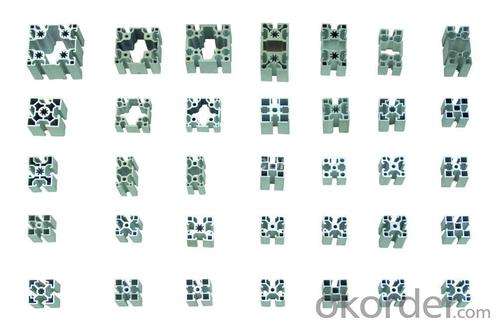

Aluminum Alloy Profiles - Slot Aluminium Profiles Extrusions

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetal with appearance ranging from silvery to dull gray,depending on the surface roughness. It is nonmagnetic and does not easilyignite. A fresh film of aluminium serves as a good reflector (approximately92%) of visible light and an excellent reflector (as much as98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffnessof steel. It iseasily machined,cast, drawn and extruded.

Aluminum Profile

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

- Q: Can aluminum profiles be utilized for creating distinctive architectural designs, and if yes, what are the ways to achieve this?

- <p>Yes, aluminum profiles can be used to create unique architectural designs. They are favored for their strength, light weight, and corrosion resistance, which allow for innovative and sustainable building solutions. Architects can use aluminum profiles in various ways: as structural components in curtain walls, as decorative elements in facades, or as supports in roof structures. The profiles can be custom-cut and shaped to fit specific design requirements, and they can be combined with glass or other materials to create a harmonious blend of aesthetics and functionality. Additionally, aluminum's recyclability and low maintenance make it an environmentally friendly choice for architectural projects.</p>

- Q: Is it possible to utilize aluminum profiles in the construction of residential buildings or homes?

- <p>Yes, aluminum profiles can be used in residential buildings and houses. They are valued for their durability, low maintenance, and resistance to corrosion. Aluminum profiles are commonly used in window frames, door frames, and as structural components due to their strength and lightweight properties. They also offer good thermal insulation and can be easily painted or finished to match the aesthetic of the building.</p>

- Q: Do aluminum profiles require any special maintenance?

- Aluminum profiles do not require any special maintenance. Aluminum is a durable and low-maintenance material that is resistant to corrosion, rust, and weathering. Unlike other materials such as wood or steel, aluminum profiles do not need to be regularly painted, stained, or treated to maintain their appearance or functionality. Additionally, aluminum is lightweight, making it easy to handle and install. However, it is important to keep the aluminum profiles clean by regularly removing dirt or debris with a mild detergent and water solution. This will help to preserve the aesthetic appeal and longevity of the profiles. Overall, aluminum profiles are a convenient and hassle-free option for various applications, as they do not require any special maintenance.

- Q: Can aluminum profiles be used in the construction of modular buildings?

- Yes, aluminum profiles can be used in the construction of modular buildings. Aluminum profiles offer several advantages such as being lightweight, durable, corrosion-resistant, and easily recyclable. These profiles can be easily fabricated and assembled to create strong and stable modular structures. Additionally, aluminum profiles provide flexibility in design, allowing for customization and versatility in modular construction projects.

- Q: This question asks for an explanation of the various types of aluminum profiles that are specifically used in the manufacturing and construction of windows and doors.

- <p>Aluminum profiles for windows and doors come in various types, each serving specific functions and designs. Common types include: 1) Casement profiles, used for side frames and meeting stiles in casement windows; 2) Mullion profiles, for vertical and horizontal structural members in window walls; 3) Transom profiles, used in the top or bottom of windows to support glazing; 4) Sash profiles, forming the main frame of the window sash; 5) Threshold profiles, used at the bottom of doors for weather sealing; 6) Header profiles, supporting the top of a door or window opening; and 7) Specialty profiles, designed for specific architectural needs like corner posts or decorative elements. Each profile is engineered for strength, durability, and compatibility with glazing and浜旈噾閰嶄欢.</p>

- Q: How do you select the appropriate aluminum profile for a specific application?

- When choosing the right aluminum profile for a particular application, several important factors should be taken into account. To begin with, it is crucial to have a clear understanding of the application's requirements and specifications. This entails considering elements such as load-bearing capacity, structural integrity, and overall functionality needed for the application. Afterwards, it becomes essential to assess the attributes of the available aluminum profiles. This involves considering aspects such as alloy composition, strength, hardness, and corrosion resistance. Each application may have specific requirements in order to achieve optimal performance and durability. Moreover, it is important to evaluate the dimensions and shape of the aluminum profile. This includes considering factors like length, width, and thickness required for the application. Additionally, the shape of the profile, whether it is square, rectangular, or custom-designed, should also be taken into consideration. Another aspect to be taken into account is the surface finish of the aluminum profile. Depending on the specific application, the surface may need to be smooth, textured, or treated in order to enhance appearance or provide additional protection against wear, abrasion, or corrosion. Furthermore, it is essential to consider the availability and cost of the chosen aluminum profile. Evaluating the availability of the required profiles from different suppliers and assessing their cost-effectiveness is crucial to ensure that the chosen profile aligns with the budget and project timeline. Lastly, seeking expert advice and consulting with professionals who have experience in aluminum profiles for specific applications can be highly beneficial. They can offer valuable insights and recommendations based on their knowledge and expertise. In conclusion, selecting the appropriate aluminum profile for a specific application involves considering factors such as the application's requirements, the characteristics of the aluminum profile, dimensions and shape, surface finish, availability, cost, and seeking expert advice. By carefully considering these factors, one can choose the most suitable aluminum profile that will effectively meet the requirements of the application.

- Q: Are there any fire safety considerations when using aluminum profiles?

- Yes, there are fire safety considerations when using aluminum profiles. Although aluminum itself is not combustible, it can still contribute to the spread and intensity of a fire. Aluminum profiles, especially when used in construction or industrial applications, can act as fuel for a fire and potentially increase its severity. One important consideration is the fire rating of the aluminum profiles. Fire ratings indicate the length of time a material can withstand exposure to fire before it fails. It is crucial to select aluminum profiles with appropriate fire ratings that align with the specific requirements of the application. This ensures that the profiles can delay the spread of fire, providing valuable time for evacuation and firefighting efforts. Another consideration is the use of appropriate insulation materials. Aluminum profiles are often used in building facades, curtain walls, and other structural applications. In such cases, it is important to ensure that the insulation materials used with the aluminum profiles are fire-resistant. This helps prevent the fire from spreading through the building envelope and reduces the risk of structural failure. Additionally, fire safety measures should be implemented during the installation process. Proper firestopping techniques should be employed to seal any gaps or penetrations around the aluminum profiles. This helps prevent the passage of flames, smoke, and hot gases from one compartment to another, limiting the fire's spread. Regular maintenance and inspection of the aluminum profiles are also essential for fire safety. Any damage or deterioration should be promptly addressed to prevent potential fire hazards. Additionally, proper fire detection and suppression systems should be in place to detect and control fires in a timely manner. Overall, while aluminum profiles themselves may not be combustible, it is important to consider various fire safety measures when using them in construction or industrial applications. By selecting appropriate fire-rated profiles, using fire-resistant insulation materials, implementing proper installation techniques, and maintaining regular inspections, the risk of fire can be minimized, ensuring the safety of occupants and property.

- Q: How are the tonnage grades of aluminum extrusion machines classified?

- Aluminum Alloy stamping metal iron because material is relatively soft, expensive, easy to break and some Aluminum Alloy products also need subsequent processing, such as drawing, anode processing, especially in stamping production to produce top injuries, scratches, in the mold manufacturing should pay special attention to the following:1, for the project does not affect the number of cases, punching as far as possible behind the project, punching, and even for punching a large number of products, may consider more than one project, but also the punching line in the back.2, aluminum material is soft, and the mold is easy to block material, so in the design of mold gap should be put bilateral material thickness of 10% gap, the knife edge straight depth to 2MM is more appropriate, the taper to 0.8-1 degrees is appropriate.3, bending forming, because aluminum material in bending when easy to produce aluminum chip, will cause spot injury, indentation, aluminum raw material needs to stick PE film, in the roller and electroplating case, forming block with polishing hard chromium is better.4, the need for anode processing after stamping, such as pressing and flattening process of 180 degrees, the product can not be completely pressed, completely pressed will spit acid phenomenon for 0.2-0.3MM seam, acid to timely outflow, so we must do this step on the limiting block and calibration mode is higher than the norm out on.5, because the aluminum material is crisp, easy to crack, especially in the case of anti flanging, so try not to do the line, even if you want to do, but also to make the line width a little bit, a little lighter.6, all aluminum blade are required to use wire cut, to prevent the burrs and blanking is not smooth, easy to produce high temperature aluminum, so the punch hardness requirements of more than 60 degrees, at least with SKD11 material, has no D2 arithmetic matter punch.

- Q: Can aluminum profiles be used in the construction of playground equipment?

- Yes, aluminum profiles can be used in the construction of playground equipment. Aluminum is lightweight, durable, and resistant to corrosion, making it an ideal material for playground structures. It is also easy to shape and customize, allowing for the creation of various designs and structures. Additionally, aluminum profiles can be coated or painted to enhance aesthetics and protect against weathering. Overall, aluminum profiles offer several advantages for playground equipment construction.

- Q: What are the advantages and disadvantages of the use of magnesium profiles compared with aluminum profiles?

- 5 specific gravity density: under the same volume conditions, magnesium alloy is lighter than aluminum alloy, which is the advantage of magnesium alloy.6 modulus of elasticity: the frame made of magnesium alloy is more rigid than aluminum alloy frame, and the frame made of the same thickness and caliber can absorb more trampling force when riding, which will influence riding efficiency.

Send your message to us

Aluminum Alloy Profiles - Slot Aluminium Profiles Extrusions

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords