Wholesale Anodized Aluminum Profiles for Construction Application in Cars

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

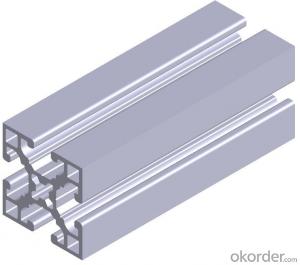

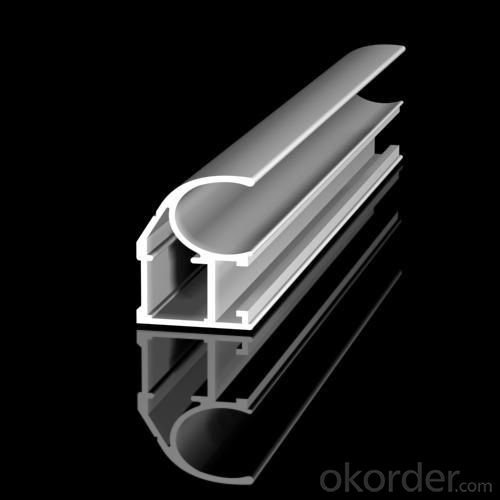

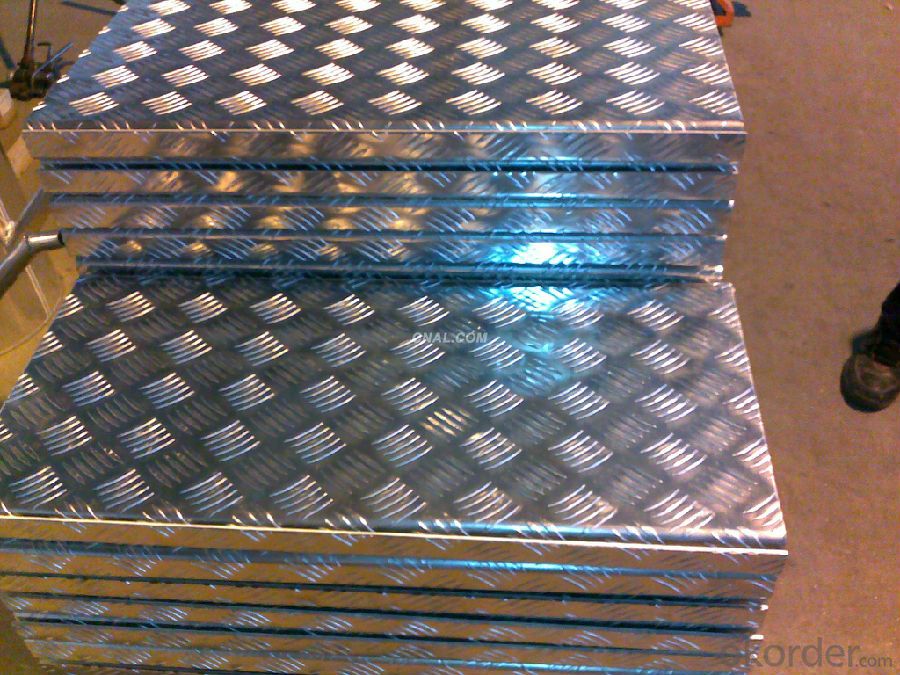

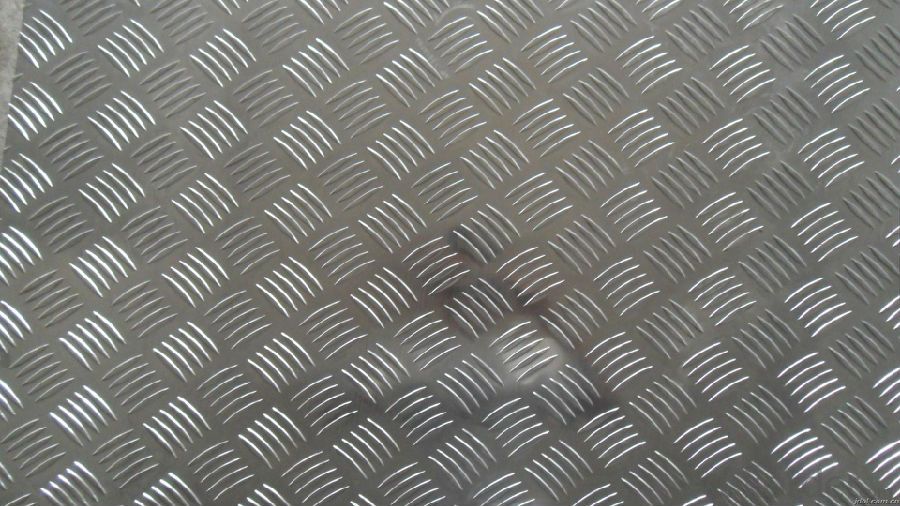

Structure of Aluminium Plate for Construction Application in Cars Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of theAluminium Plate for Construction Application in Cars:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

Images of the Aluminium Plate for Construction Application in Cars:

Aluminium Plate for Construction Application in Cars Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: What are the surface hardness properties of aluminum profiles?

- The surface hardness properties of aluminum profiles can vary depending on the specific alloy and treatment processes applied. Aluminum alloys are generally known for having a lower hardness compared to other metals such as steel. However, through various treatments, aluminum profiles can achieve improved surface hardness. One common treatment method is anodizing, which involves creating an oxide layer on the surface of the aluminum. This process not only enhances the corrosion resistance of the profiles but also increases their surface hardness. Anodized aluminum profiles can have a hardness ranging from 150 to 300 HV (Vickers hardness), depending on the thickness of the oxide layer. Another treatment process is hard coating, where a ceramic material such as aluminum oxide is applied to the surface of the profiles. This coating significantly enhances the hardness of the aluminum, providing a greater level of wear resistance. The hardness of hard-coated aluminum profiles can range from 400 to 600 HV or even higher. It is important to note that the specific hardness properties can vary depending on the alloy composition, surface treatment method, and the desired application of the aluminum profiles. Therefore, it is crucial to consult with manufacturers or suppliers to determine the appropriate hardness properties that best suit your specific needs.

- Q: Can aluminum profiles be used for creating protective enclosures?

- Indeed, protective enclosures can be fashioned using aluminum profiles. Aluminum, being a lightweight, long-lasting, and corrosion-resistant substance, proves itself fitting for a plethora of purposes, including protective enclosures. By effortlessly fabricating and assembling aluminum profiles, one can generate tailored enclosures of diverse dimensions and forms. They grant exceptional structural integrity and endure even the harshest environmental circumstances. Furthermore, in the event that efficient heat dispersal is necessary, aluminum profiles present commendable thermal conductivity. All in all, the versatility, strength, and durability of aluminum profiles render them a favored choice for the creation of protective enclosures.

- Q: How do aluminum profiles compare to plastic profiles?

- Various industries commonly use aluminum profiles and plastic profiles for different purposes. When comparing these two materials, there are several factors that need consideration. Strength and durability are important factors to consider. Generally, aluminum profiles are stronger and more durable than plastic profiles. Aluminum possesses high tensile strength, enabling it to withstand heavy loads and resist deformation. Conversely, plastic profiles are more prone to cracking or breaking under excessive stress. Another factor to consider is weight. Aluminum profiles are heavier compared to plastic profiles. This characteristic can be advantageous or disadvantageous depending on the specific application. The weight of aluminum can provide stability and strength, while the lightweight nature of plastic makes it easier to handle and install. Corrosion resistance is also a significant aspect to examine. Aluminum profiles exhibit excellent corrosion resistance properties, enabling them to endure exposure to various environmental conditions. This makes them suitable for outdoor applications. In contrast, plastic profiles are not as resistant to certain chemicals or UV radiation, which can cause degradation over time. Flexibility and design are important considerations as well. Plastic profiles offer greater design flexibility compared to aluminum profiles. Plastic can be molded easily into complex shapes and customized to meet specific requirements. Aluminum, although less flexible, can still be shaped or extruded into different profiles within certain limitations. Thermal and electrical conductivity should also be taken into account. Aluminum profiles have superior thermal conductivity, allowing them to dissipate heat more effectively. Consequently, they are often used in applications where heat dissipation is critical, such as electronics or heat sinks. Plastic profiles, on the other hand, have lower thermal conductivity and are less suitable for such applications. Cost is another factor to consider. Generally, plastic profiles are more cost-effective than aluminum profiles. The manufacturing process for plastic profiles is simpler and cheaper, resulting in lower production costs. Conversely, aluminum profiles require more advanced manufacturing techniques and additional finishing processes, making them relatively more expensive. In conclusion, the choice between aluminum and plastic profiles depends on the specific requirements of the application. Aluminum profiles offer superior strength, durability, and corrosion resistance, making them suitable for heavy-duty or outdoor applications. On the other hand, plastic profiles provide more design flexibility and cost-effectiveness, making them ideal for lightweight or customized applications.

- Q: Can aluminum profiles be used in marine vessel manufacturing?

- Yes, aluminum profiles can be used in marine vessel manufacturing. Aluminum is a popular choice for constructing boats and other marine vessels due to its unique properties. Aluminum is lightweight, strong, and corrosion-resistant, making it well-suited for marine environments. It can withstand exposure to saltwater, which is a common challenge in marine applications. Additionally, aluminum profiles can be easily formed, welded, and joined together, allowing for efficient and customizable vessel designs. This versatility makes aluminum an attractive option for boat builders and manufacturers.

- Q: What is the difference between aluminum profile and sheet metal?

- Aluminum extrusions can be produced by extrusion or casting. In contrast, the aluminum sheet is flat, mainly for all types of surface.

- Q: How to distinguish the true and false of aluminum profile

- 1. Light weight 2. 3 and after the incision is white within 4 hard, very fine very hard

- Q: Can aluminum profiles be used for furniture?

- Yes, aluminum profiles can be used for furniture. Aluminum is a lightweight, durable, and corrosion-resistant material, making it suitable for various furniture applications such as tables, chairs, and frames. It offers versatility in design, allowing for sleek and modern aesthetics. Additionally, aluminum profiles can be easily customized and are available in different finishes, making them a popular choice in the furniture industry.

- Q: This question asks about the methods to ensure that aluminum profiles used in construction meet safety standards.

- <p>To ensure that aluminum profiles used in building construction meet safety standards, you should follow these steps: 1) Source from reputable suppliers who adhere to industry standards. 2) Check for certifications such as ISO 9001 for quality management. 3) Verify the aluminum's grade and alloy type to ensure it's suitable for construction use. 4) Conduct regular inspections and tests, including tensile strength and load-bearing capacity tests. 5) Adhere to local building codes and regulations. 6) Use profiles with appropriate thickness and dimensions for the intended application. 7) Consult with engineers or architects to ensure proper design and installation. 8) Keep records of all tests and inspections for future reference and compliance checks.</p>

- Q: The latest list of aluminum China

- The first aluminum aluminum (China Aluminum Group, the central management of large state-owned enterprises)Second of Asia Aluminum (Asia Aluminum Group, Asia's largest aluminum producer, Chinese brand)Third strong aluminum products (China famous brand, national inspection free products)Fourth (Chinese Fenglv aluminum material brand, national Mianjian products)Fifth Zhong Zhong aluminum (China famous brand, China well-known trademark, national inspection free products)Sixth (Chinese Hing Fat aluminum brand, A Well-Known Trademark in China, national Mianjian products)Seventh South Asia Aluminum profiles (China famous brand, national inspection free products)Eighth Nanshan aluminum (China famous brand, China well-known trademark, national inspection free products)Ninth by court aluminum profiles (China well-known trademarks, national inspection free products)Albert tenth aluminum (China famous brand, national inspection free products)

- Q: What specific criteria or standards must be met when utilizing aluminum profiles in the construction of environmentally friendly buildings?

- <p>In green building construction, aluminum profiles must meet certain sustainability and environmental requirements. These include high recyclability to reduce waste, low embodied energy to minimize environmental impact during production, and adherence to standards like LEED certification. Profiles should also be durable and low-maintenance to reduce the need for replacement and associated waste. Additionally, the use of eco-friendly coatings and finishes that do not release harmful substances is crucial. Compliance with regional green building codes and regulations is also mandatory.</p>

Send your message to us

Wholesale Anodized Aluminum Profiles for Construction Application in Cars

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords