Bosch Aluminum Extrusion Profiles for Construction Application - Aluminum Anodizing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

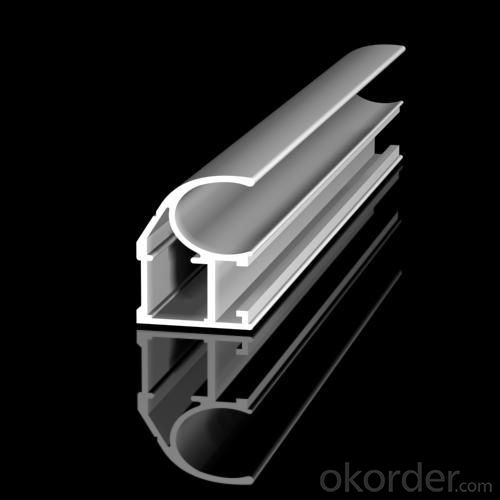

Structure of Aluminium Anodizing for Construction Application Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Anodizing for Construction Application:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

Images of the Aluminium Anodizing for Construction Application:

Aluminium Anodizing for Construction Application Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ Aluminium Cast Slab not Alloyed in Coil Form:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: What are the methods to reduce waste from aluminum profiles in construction?

- <p>To minimize waste generated from using aluminum profiles in building construction, consider the following strategies: 1) Accurate planning and design to reduce offcuts. 2) Utilize modular designs to maximize material usage. 3) Implement recycling programs to repurpose leftover profiles. 4) Opt for suppliers that provide aluminum profiles cut to exact specifications. 5) Educate workers on proper handling and waste reduction techniques. 6) Use digital tools for precise cutting to minimize material waste. 7) Encourage the use of aluminum due to its high recyclability and low energy consumption in the recycling process.</p>

- Q: This question asks if there are any health hazards linked to handling aluminum profiles.

- <p>Generally, working with aluminum profiles does not pose significant health risks. Aluminum is a lightweight, corrosion-resistant metal that is widely used in various industries. However, inhalation of aluminum dust or fumes over long periods may cause respiratory issues. Workers should use appropriate personal protective equipment (PPE) such as masks and gloves to minimize exposure. Additionally, aluminum can cause skin irritation in some individuals, so skin contact should be avoided. It's important to follow safety guidelines and maintain good hygiene practices when working with aluminum profiles.</p>

- Q: This question asks if aluminum profiles are suitable for both exterior and interior uses.

- <p>Yes, aluminum profiles can be used for both exterior and interior applications. They are popular for exterior use due to their resistance to weather and corrosion, making them ideal for construction and architectural projects. For interior applications, aluminum profiles are valued for their strength, lightweight, and aesthetic appeal, often used in furniture, window frames, and decorative elements. Their versatility and durability make them a preferred choice in various settings.</p>

- Q: This question asks about the measures to be taken to ensure that the manufacturing process for aluminum profiles complies with environmental regulations.

- <p>To ensure that the production process for aluminum profiles meets environmental standards, you should implement a comprehensive environmental management system. This includes adhering to regulations on emissions, waste disposal, and resource usage. Monitor and reduce energy consumption, use eco-friendly materials, and optimize production processes to minimize waste. Regularly assess environmental impact, conduct audits, and seek certifications like ISO 14001. Engage in continuous improvement, invest in green technologies, and educate employees on environmental responsibilities. Collaborate with suppliers to ensure they also meet environmental standards.</p>

- Q: Are there any specific safety precautions when working with aluminum profiles?

- Yes, there are specific safety precautions when working with aluminum profiles. These include wearing appropriate personal protective equipment such as gloves, safety glasses, and hearing protection. It is also important to ensure proper ventilation in the workspace to prevent inhalation of aluminum dust or fumes. Additionally, precautions should be taken to avoid sharp edges and use proper lifting techniques to prevent injury.

- Q: What are the specific needs or standards for utilizing aluminum profiles in cold weather conditions?

- <p>In cold climates, aluminum profiles must meet certain requirements to ensure durability and functionality. These include resistance to extreme temperatures, which may affect the material's strength and flexibility. Profiles should be made from high-quality aluminum alloys designed for low-temperature performance. Additionally, proper thermal breaks may be necessary to prevent heat loss through the profile. Corrosion resistance is also crucial, as cold environments can accelerate the process. Lastly, it's essential to consider the expansion and contraction of aluminum in cold temperatures, ensuring the design accommodates these changes to prevent warping or cracking.</p>

- Q: What is the relationship between aluminum alloy and aluminum alloy?

- First, according to use can be divided into the following categories: 1. building doors and windows, aluminum doors and windows [1] (divided into two windows and curtain walls). Special aluminum radiator 2. CPU radiator 3. Aluminum Alloy shelf aluminum profile, the difference between them is that the different cross-sectional shapes. They are produced by hot melt extrusion 4.. Industrial aluminum: mainly used in automation equipment, sealing cover skeleton and the custom mold machinery and equipment according to their own requirements, such as assembly line conveyor belt, hoisting machine, glue machine, testing equipment, electronic machinery industry and clean room with the majority!

- Q: The number of aluminum profiles can be meters or KG. How exactly is it? How do you understand that?

- According to the calculated root.The general material company is used to calculate the weight or root. Few meters.

- Q: Are aluminum profiles suitable for decorative applications?

- <p>Yes, aluminum profiles are commonly used for decorative purposes. They offer a sleek, modern look and are lightweight, durable, and resistant to corrosion. They can be anodized or powder coated in various colors to match different design aesthetics. Aluminum profiles are versatile and can be used in architectural features, furniture, and various other decorative elements.</p>

- Q: Are aluminum profiles suitable for modular office systems?

- Aluminum profiles prove to be a suitable choice for modular office systems. The lightweight and versatile nature of aluminum grants it several advantages in this field. To begin with, the durability and remarkable strength-to-weight ratio of aluminum profiles make them a fitting support for various office structures and components. They can withstand heavy loads and ensure stability within the modular system. Moreover, aluminum profiles exhibit corrosion resistance, a crucial characteristic for office environments that may be susceptible to moisture or humidity. This feature ensures the longevity and appearance of the modular office system over time. Furthermore, aluminum profiles offer a high degree of design flexibility, enabling customization and adaptation to different office layouts and requirements. They can be easily modified, cut, and assembled to create a modular system that caters to specific needs. This adaptability also allows for future expansion or reconfiguration of the office space. Additionally, aluminum profiles are environmentally friendly as they are recyclable and possess a low carbon footprint compared to other materials. This aligns with the growing trend of sustainable and eco-friendly office design. In conclusion, due to their durability, corrosion resistance, design flexibility, and environmental benefits, aluminum profiles are highly suitable for modular office systems.

Send your message to us

Bosch Aluminum Extrusion Profiles for Construction Application - Aluminum Anodizing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords