China Aluminum Alloy Extrusion Profiles for Aluminium Profile Anodizing for Windows and Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Profile Anodizing for Windows and Doors Description:

We have more than 10 years experiences on manufacturing kinds of aluminum profiles, such as Aluminum Window & Door profiles, Aluminum tile trim profiles, Aluminum profiles for LED light, Round/Square General profiles, Aluminum heat sink, Aluminum heating insulation profiles, Curtain wall Aluminum profiles, and others Industry profiles.

Our products have exported to all over the world, and we also have a large of market share in Algeria, Angola, Philippine, Guinea, Ghana, South Africa, Nepal, Nigeria, Tanzania, Iraq etc.

Main Features of the Aluminium Profile Anodizing for Windows and Doors:

1, Strong R&G: help customers finalize the design, strong tool design ability, excellent, pressing and surface treatment technology;

2, Strong quality management: ISO&SGS SYSTEM;

3, 24 hours on-line communication, professional, patient, flexible;

4, High capacity of manufacturing and wide range of products;

5, We can provide secondary manufacturing.

6, High corrosion resistance, high weather resistance and good wear resistance.

7, Alternative surface treatment: Colorful ANODIZE, POWDER COATING, ELECTROPHORESIS & WOODEN GRAIN. Plentiful colors upon your needs.

8, Excellent material for smooth and subtle edges, elegant appearance.

9, Strong coated adhesion which is suitable for construction and industrial material.

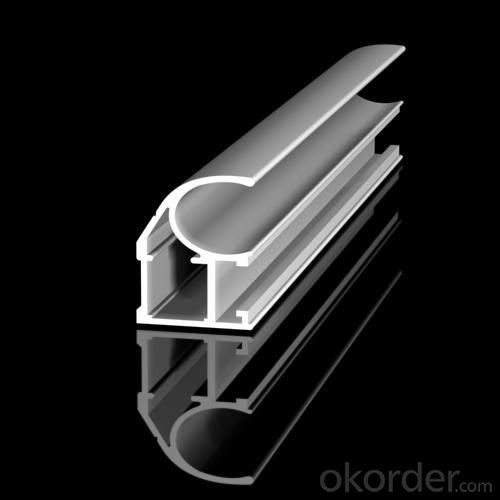

Images of the Aluminium Profile Anodizing for Windows and Doors:

Aluminium Profile Anodizing for Windows and Doors Specification:

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q: How do you cut and shape aluminum profiles?

- To cut and shape aluminum profiles, there are several methods you can use depending on the desired outcome and the tools you have available. Here are three common techniques: 1. Cutting with a hacksaw or miter saw: This is the most basic and accessible method. Using a hacksaw or a miter saw with an aluminum cutting blade, mark the desired length on the profile and carefully cut through it. Ensure you have a secure grip on the profile and make slow, steady cuts to avoid excessive vibration or the blade getting stuck. 2. Using a power saw or circular saw: For larger or thicker aluminum profiles, a power saw or circular saw with a specialized aluminum cutting blade will make the job faster and easier. Measure and mark the desired length on the profile, then secure it firmly in place. Using the power saw, slowly and steadily cut through the profile, ensuring you have a firm grip and maintaining control throughout the process. 3. Shaping with a file or grinder: Once the profile is cut to the desired length, you may need to shape or smooth the edges. This can be done using a file or grinder with an aluminum grinding wheel or sanding disc. Carefully work the file or grinder along the edges, shaping or smoothing them as needed. Take care not to apply too much pressure, as aluminum can heat up quickly and may distort or become damaged. Remember to wear appropriate safety gear, such as gloves and eye protection, when working with aluminum profiles. Additionally, it's always a good idea to practice on scrap pieces first to familiarize yourself with the techniques and tools before working on the final product.

- Q: Fenglv aluminum material how ah? What aluminum materials do you use for windows and doors?

- Economic point of view, choose plastic film packaging materials. Yes, the price of the material must be more expensive, at one price per share.

- Q: Can aluminum profiles be custom-designed?

- Yes, aluminum profiles can be custom-designed to meet specific requirements and specifications. The flexibility and versatility of aluminum as a material allow for various shapes, sizes, and finishes, making it suitable for customization in various industries such as construction, automotive, and manufacturing. Custom-designed aluminum profiles can be tailored to specific applications, ensuring optimal functionality and aesthetics.

- Q: What are the different colors available for aluminum profiles?

- There are several different colors available for aluminum profiles, allowing for endless possibilities in design and aesthetics. Some of the most common colors include silver, black, bronze, and white. These colors are achieved through various finishing techniques such as anodizing and powder coating. Anodizing involves creating a protective oxide layer on the surface of the aluminum, which can be dyed to achieve different colors. Powder coating, on the other hand, involves applying a dry powder paint to the aluminum and then curing it under heat, resulting in a durable and vibrant finish. Additionally, custom colors can also be created through the use of specialized coatings and finishes. Overall, the availability of different colors for aluminum profiles allows for versatility in architectural, industrial, and decorative applications.

- Q: Including the element parameters, the price and the difference between 6063, what is the use and so on!How about 6060 100/ meters? How much is the strength? How much is the price more than 6063?

- 6060 aluminum material compositionSi:0.3-0.6, Fe:0.1-0.3, Cu:0.1, Mn:0.1, Mg:0.35-0.6, Cr:--, Zn:0.1, others:Ti:0.15 other total: 0.15 Al: marginPerformance: tensile strength B (MPa): more than 470 conditions yield strength of 0.2 (MPa): more than 420 elongation 5 (%): 6Product features: 1. high strength, heat treatable alloy.2., good mechanical properties,.3. good usability,.4. easy processing, good wear resistance,.5. corrosion resistance, good oxidation resistanceMain uses: Aviation fixtures, truck, tower building, ships, pipelines and other applications requiring strength, weldability and corrosion resistance of the building on the field. Such as: aircraft parts, camera lens, coupler, ship fittings and accessories, electronic accessories and fittings, decoration or various hardware, hinge head head, piston, piston, hydraulic brake, electric appliance fittings, valves and valve parts.6063 aluminum chemical composition:Al Al: residual silicon Si:0.20 ~ 0.6 copper Cu: less than 0.10 mg Mg:0.45 ~ 0.9 zinc Zn: Mn: Mn = 0.10 = 0.10 Ti = 0.10 Cr: titanium chromium iron: less than or equal to 0.10 Fe:0.000 ~ 0.350 note: single: = 0.05; total: 0.15The density of 6063 is 2.69g/cm3

- Q: How to distinguish aluminum alloy series?

- Each breed has its serial number, but each factory is different

- Q: How do aluminum profiles perform in terms of water resistance?

- Aluminum profiles generally exhibit good water resistance due to their natural properties. The metal itself is corrosion-resistant, which means it does not easily rust or degrade when exposed to water. Additionally, aluminum profiles can be further treated with coatings or anodization processes to enhance their water resistance capabilities. These surface treatments create a protective layer that prevents water from penetrating the metal, reducing the risk of damage or deterioration over time. However, it is important to note that the water resistance of aluminum profiles can vary depending on the specific alloy, surface treatment, and maintenance practices. Regular cleaning and proper sealing of joints can help ensure optimal water resistance performance.

- Q: What are the differences between standard and non - standard shapes?

- This is not an exact statement for aluminum standard and non - standard, if only to meet the standards is not comprehensive, such as building materials and industrial aluminum profiles of the points, take the building materials, building materials have Aluminum Alloy standard GB5237.1-6-2008, in this standard, the size of section tolerance, mechanical properties, surface treatment quality by grade are made clear, such as the wall thickness profiles allow positive and negative tolerance. The provisions of the standard aluminum doors and windows, for aluminum windows, the wall thickness must be greater than 1.4mm, used for aluminum doors, and its wall thickness must be greater than 2mm. Thus, the aluminum should be standard and non-standard argument, but the qualified and unqualified products, for material strength, surface treatment quality, form and position tolerance must meet the standard requirements for wall thickness according to the thickness of the corresponding use of selected aluminum.

- Q: What are the differences between the 6005 and 6003 aluminum profiles?Yangmingxg3

- 6003 of the magnesium content is higher than 6005, and the strengthening of magnesium to aluminum is remarkable. With the addition of 1% mg, the tensile strength increases by about 34MPa.

- Q: This question asks for the various types of paint that can be used to protect aluminum profiles from weathering.

- <p>Aluminum profiles can be protected from weathering through the application of different types of paints. These include: 1) Powder Coating, which provides a durable and weather-resistant finish. 2) Anodizing, a process that increases the thickness of the natural oxide layer on aluminum, enhancing its resistance to corrosion. 3) Liquid Coatings, such as acrylic or polyester-based paints, which offer a range of colors and finishes. 4) Fluorocarbon Paints, known for their excellent resistance to UV rays and weathering. Each type has its own advantages and is chosen based on the specific requirements for durability, appearance, and environmental conditions.</p>

Send your message to us

China Aluminum Alloy Extrusion Profiles for Aluminium Profile Anodizing for Windows and Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords