All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How are aluminum profiles used in the development of energy-efficient healthcare facilities and hospitals?

Aluminum profiles are used in the development of energy-efficient healthcare facilities and hospitals in various ways. They are commonly utilized in the construction of windows, doors, and curtain wall systems, helping to enhance the thermal insulation and overall energy efficiency of the building envelope. The lightweight nature of aluminum profiles also allows for easier installation and maintenance. Additionally, these profiles can be customized to accommodate energy-saving glazing options, such as low-emissivity glass, which further contributes to reducing energy consumption and creating a comfortable environment for patients and staff.

How do you calculate the energy efficiency and environmental impact of projects involving aluminum profiles?

To calculate the energy efficiency and environmental impact of projects involving aluminum profiles, several factors need to be considered. Firstly, the energy required for the extraction, refining, and processing of aluminum should be taken into account. This includes the energy consumed during mining, smelting, and shaping the profiles. Secondly, the transportation of raw materials, as well as the finished products, should be considered to assess the carbon footprint associated with the project. Additionally, the energy efficiency of the manufacturing process, such as the use of energy-efficient machinery and recycling practices, will impact the overall energy efficiency. Finally, the end-of-life considerations, including recycling or disposal methods, should be evaluated to determine the environmental impact. By analyzing these factors, one can calculate the energy efficiency and environmental impact of projects involving aluminum profiles.

What are the safety measures and precautions when handling and installing aluminum profiles?

When handling and installing aluminum profiles, there are several safety measures and precautions that should be followed. Firstly, it is important to wear appropriate personal protective equipment (PPE) such as gloves and safety glasses to protect against cuts and eye injuries. Additionally, it is crucial to handle the profiles with care and avoid dragging or dropping them to prevent damage or potential accidents.

During installation, it is essential to ensure a stable and secure work surface to avoid any slips or falls. Adequate ventilation should be maintained to prevent the accumulation of dust or fumes that may be generated during the installation process. When cutting or drilling aluminum profiles, proper tools and techniques should be used to minimize the risk of injury.

Furthermore, it is important to be aware of any electrical hazards and take necessary precautions, such as turning off power sources when working with aluminum profiles near electrical equipment or wiring. Lastly, following manufacturer's guidelines and instructions for installation and handling is crucial to ensure safe practices and prevent any potential accidents or injuries.

What are the fastening methods for aluminum profiles?

There are several fastening methods commonly used for aluminum profiles, including screws, bolts, rivets, and adhesive bonding. Each method offers its own advantages and is chosen based on factors such as the application requirements, load-bearing capacity, aesthetics, and ease of assembly.

Wholesale Aluminum Profiles from supplier in Ecuador

Our team of experts will guide you through the entire process, from selecting the right profiles for your specific requirements to ensuring timely delivery. We understand the importance of quality and reliability, which is why we work with trusted manufacturers to source the best aluminum profiles in the industry.

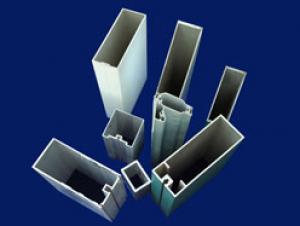

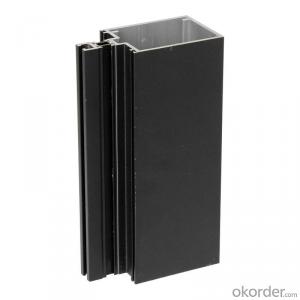

Whether you are in need of standard profiles or customized solutions, we have the capabilities to meet your demands. Our comprehensive range includes profiles for windows and doors, curtain walls, industrial applications, transportation, and more. We also offer various surface finishes, such as anodizing, powder coating, and wood grain, to suit your aesthetic preferences.

In addition to our product offerings, we provide sales and quotation services to help you make informed decisions. Our team will analyze your project requirements and provide competitive pricing, ensuring that you receive the best value for your investment. We also offer technical support services, assisting you with any questions or concerns you may have regarding the installation or application of our aluminum profiles.

As a subsidiary of CNBM, we have access to a vast network of resources and expertise. This allows us to stay up-to-date with the latest industry trends and technologies, ensuring that we can provide you with the most innovative solutions. Our goal is to not only meet but exceed your expectations, providing you with exceptional products and services.

Contact us today to discuss your aluminum profiles needs in Ecuador. We look forward to partnering with you and contributing to the success of your projects.

Whether you are in need of standard profiles or customized solutions, we have the capabilities to meet your demands. Our comprehensive range includes profiles for windows and doors, curtain walls, industrial applications, transportation, and more. We also offer various surface finishes, such as anodizing, powder coating, and wood grain, to suit your aesthetic preferences.

In addition to our product offerings, we provide sales and quotation services to help you make informed decisions. Our team will analyze your project requirements and provide competitive pricing, ensuring that you receive the best value for your investment. We also offer technical support services, assisting you with any questions or concerns you may have regarding the installation or application of our aluminum profiles.

As a subsidiary of CNBM, we have access to a vast network of resources and expertise. This allows us to stay up-to-date with the latest industry trends and technologies, ensuring that we can provide you with the most innovative solutions. Our goal is to not only meet but exceed your expectations, providing you with exceptional products and services.

Contact us today to discuss your aluminum profiles needs in Ecuador. We look forward to partnering with you and contributing to the success of your projects.