All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

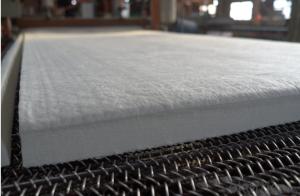

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Monolithic RefractoriesView More

Ceramic Fiber ProductsView More

Refractory BricksView More

Raw Materials For RefractoryView More

Q & A

What are the common refractory materials used in petrochemical plants?

The common refractory materials used in petrochemical plants include firebricks, castables, and refractory ceramic fibers. These materials are chosen for their high heat resistance and ability to withstand corrosive environments found in petrochemical processes.

What are the refractory materials used in the non-ferrous metal industry?

Refractory materials commonly used in the non-ferrous metal industry include magnesia, alumina, silica, and zirconia-based refractories.

What is the role of refractory materials in glass manufacturing?

Refractory materials play a crucial role in glass manufacturing by providing a heat-resistant lining for furnaces and kilns. These materials are designed to withstand extremely high temperatures and prevent the molten glass from corroding or sticking to the furnace walls. Additionally, refractory materials help maintain a controlled and uniform temperature within the furnace, ensuring efficient and consistent glass production.

Wholesale Refractory Materials from supplier in Ecuador

With a strong presence in the Ecuadorian market, we understand the specific requirements and challenges you may face when it comes to sourcing high-quality Refractory Materials. Our team of experts is well-versed in the technical aspects of these materials and can provide you with accurate and reliable advice on choosing the right products for your projects.

As a subsidiary of CNBM, we have access to a vast network of suppliers and manufacturers, allowing us to offer a wide range of Refractory Materials to meet your specific needs. Whether you require materials for high-temperature applications, insulation purposes, or any other refractory requirements, we have the expertise and resources to fulfill your demands.

In addition to our product offerings, we also provide comprehensive sales and technical support services. Our dedicated sales team is committed to understanding your unique requirements and providing you with personalized solutions. We can assist you with product selection, pricing, and logistics, ensuring a seamless procurement process.

Moreover, our technical support services are designed to help you optimize the performance of your refractory materials. Our experienced engineers can provide guidance on installation, maintenance, and troubleshooting, ensuring that you get the most out of your investment.

At our company, we prioritize customer satisfaction and strive to build long-term partnerships with our clients. We understand the importance of timely delivery and competitive pricing, and we work diligently to meet your expectations in these areas.

Whether you are involved in the construction, steel, cement, or any other industry that requires refractory materials, we are your reliable partner in Ecuador. Contact us today to discuss your refractory materials needs, and let us provide you with the best solutions for your projects.

As a subsidiary of CNBM, we have access to a vast network of suppliers and manufacturers, allowing us to offer a wide range of Refractory Materials to meet your specific needs. Whether you require materials for high-temperature applications, insulation purposes, or any other refractory requirements, we have the expertise and resources to fulfill your demands.

In addition to our product offerings, we also provide comprehensive sales and technical support services. Our dedicated sales team is committed to understanding your unique requirements and providing you with personalized solutions. We can assist you with product selection, pricing, and logistics, ensuring a seamless procurement process.

Moreover, our technical support services are designed to help you optimize the performance of your refractory materials. Our experienced engineers can provide guidance on installation, maintenance, and troubleshooting, ensuring that you get the most out of your investment.

At our company, we prioritize customer satisfaction and strive to build long-term partnerships with our clients. We understand the importance of timely delivery and competitive pricing, and we work diligently to meet your expectations in these areas.

Whether you are involved in the construction, steel, cement, or any other industry that requires refractory materials, we are your reliable partner in Ecuador. Contact us today to discuss your refractory materials needs, and let us provide you with the best solutions for your projects.

Hot Search

- Monolithic Refractories in Bangladesh

- Ceramic Fiber Products in Iran

- Refractory Bricks in Jordan

- Raw Materials For Refractory in Namibia

- Ceramic Fiber Products in Sweden

- Monolithic Refractories in Kazakhstan

- Raw Materials For Refractory in Swaziland

- Refractory Bricks in Burundi

- Ceramic Fiber Products in Laos

- Refractory Bricks in Spain