Extrusion Aluminum Profiles for Aluminium T-Profile Windows and Doors Installation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium T-profile for Windows and Doors Instalation Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium T-profile for Windows and Doors Instalation:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

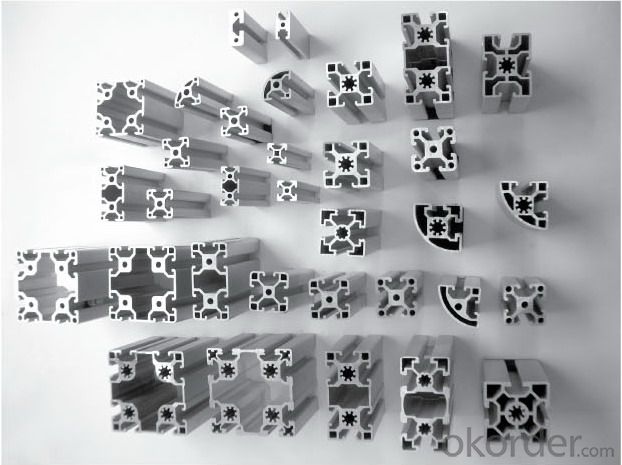

Images of the Aluminium T-profile for Windows and Doors Instalation:

Aluminium T-profile for Windows and Doors Instalation Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ Aluminium Cast Slab not Alloyed in Coil Form:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: This question asks for a list of various uses of aluminum profiles within the construction industry.

- <p>Aluminum profiles have a wide range of applications in the construction industry due to their strength, durability, and lightweight properties. They are used in window and door frames for their resistance to corrosion and ease of maintenance. They are also employed in curtain walls, which are the outer coverings of buildings, providing both aesthetic appeal and structural integrity. Aluminum profiles are utilized in the construction of scaffolding for their high strength-to-weight ratio, ensuring safety and stability. Additionally, they are used in the manufacturing of modular buildings and prefabricated structures due to their ease of assembly and disassembly. Other applications include roofing systems, flooring structures, and as support beams in various construction projects.</p>

- Q: What is the aluminum section table?

- Table characteristics: working table, using aluminum material customized special products and durable, the breakage rate of the lowest! For quality of aluminum profiles, I strongly recommend item aluminum, aluminum fortunately which do not know, do not know how the quality of aluminum is our common problem. Here is a little experience for me to share with you.

- Q: Can aluminum profiles be used for signage or display purposes?

- Certainly, signage or display purposes can definitely utilize aluminum profiles. Aluminum, a versatile and durable material, finds wide usage in several industries, including signage and display. By providing a robust framework, aluminum profiles ensure stability and longevity for signs and displays. Due to its lightweight nature, aluminum is effortless to handle and install, thus making it a favored option for both outdoor signage and indoor displays. Additionally, aluminum profiles can be easily customized and fabricated into diverse shapes and sizes, thereby allowing for creative and flexible designs. In addition, aluminum profiles possess excellent resistance against corrosion, guaranteeing the signage or display's good condition even in outdoor or high-moisture environments. This quality renders them suitable for a broad range of applications, such as storefront signs, directional signs, trade show displays, exhibition booths, and many others. Moreover, aluminum profiles can receive powder coating or anodization to impart an ornamental finish, thereby enhancing the visual appeal of the signage or display. This offers branding and customization options, thus making aluminum profiles an excellent choice for businesses aiming to showcase their brand identity. Overall, aluminum profiles serve as a dependable and versatile choice for signage or display purposes. They possess strength, durability, design flexibility, and corrosion resistance, which makes them suitable for various applications across different industries.

- Q: What are the different cutting options available for aluminum profiles?

- Aluminum profiles have various cutting options to choose from, depending on the project's specific requirements. Some commonly used cutting methods include: 1. Miter Saw: A popular choice for aluminum profiles, the miter saw utilizes a circular blade to make precise angled cuts, ensuring accuracy and cleanliness. 2. Chop Saw: Similar to the miter saw, the chop saw is also frequently employed for cutting aluminum profiles. It effortlessly creates straight cuts at 90-degree angles, making it efficient and capable of handling larger profiles. 3. Bandsaw: Offering versatility, the bandsaw utilizes a continuous looped blade to make straight cuts. It provides flexibility in terms of cutting angles and can handle thicker aluminum profiles. 4. CNC Cutting: Renowned for its precision, CNC cutting involves the use of a computer-controlled cutting machine that can follow intricate design patterns. This method is ideal for detailed and intricate cuts, guaranteeing high precision and repeatability. 5. Laser Cutting: Laser cutting is a popular choice due to its high precision and ability to create clean cuts. By using a focused laser beam to melt or vaporize the aluminum, laser cutting ensures smooth and accurate results. It is suitable for both simple and complex designs. 6. Waterjet Cutting: Waterjet cutting is a versatile method that employs a high-pressure jet of water mixed with abrasive particles to cut through aluminum profiles. It can handle various thicknesses and shapes, providing precise cuts without altering the properties of the aluminum or generating heat. 7. Shearing: A basic yet effective cutting method, shearing involves using sharp blades to trim or cut aluminum profiles. It is commonly used for straight cuts and is suitable for thinner profiles. 8. Plasma Cutting: Plasma cutting employs a high-velocity jet of ionized gas to cut through aluminum profiles. It is suitable for thicker profiles and allows for faster cutting speeds compared to other methods. These are just a few of the cutting options available for aluminum profiles. The choice of method depends on factors such as desired cut type, accuracy requirements, profile thickness, and design complexity. It is crucial to consider these factors and seek professional consultation to determine the most suitable cutting option for a specific project.

- Q: Are there any specific requirements for transporting and storing aluminum profiles?

- Yes, there are specific requirements for transporting and storing aluminum profiles. When it comes to transporting aluminum profiles, it is important to ensure that they are adequately protected to avoid any damage during transit. This can be done by using appropriate packaging materials such as foam or cardboard to provide cushioning and prevent any scratches or dents. Additionally, the profiles should be securely fastened or strapped in place to prevent movement or shifting during transportation. In terms of storage, it is crucial to store aluminum profiles in a dry and well-ventilated area to prevent any moisture accumulation, which can lead to corrosion. They should be kept away from direct sunlight and extreme temperatures, as excessive heat can cause distortion or warping of the profiles. Furthermore, it is recommended to store the profiles in a horizontal position to prevent any bending or sagging. If vertical storage is necessary, proper support should be provided to ensure that the profiles remain straight and undamaged. Overall, following these requirements for transporting and storing aluminum profiles will help maintain their integrity and ensure their quality upon arrival or when retrieved for use.

- Q: Is it possible to utilize aluminum profiles in the construction of residential buildings or homes?

- <p>Yes, aluminum profiles can be used in residential buildings and houses. They are valued for their durability, low maintenance, and resistance to corrosion. Aluminum profiles are commonly used in window frames, door frames, and as structural components due to their strength and lightweight properties. They also offer good thermal insulation and can be easily painted or finished to match the aesthetic of the building.</p>

- Q: This question asks for an explanation of the various types of aluminum profiles that are specifically used in the manufacturing and construction of windows and doors.

- <p>Aluminum profiles for windows and doors come in various types, each serving specific functions and designs. Common types include: 1) Casement profiles, used for side frames and meeting stiles in casement windows; 2) Mullion profiles, for vertical and horizontal structural members in window walls; 3) Transom profiles, used in the top or bottom of windows to support glazing; 4) Sash profiles, forming the main frame of the window sash; 5) Threshold profiles, used at the bottom of doors for weather sealing; 6) Header profiles, supporting the top of a door or window opening; and 7) Specialty profiles, designed for specific architectural needs like corner posts or decorative elements. Each profile is engineered for strength, durability, and compatibility with glazing and浜旈噾閰嶄欢.</p>

- Q: What are the different types of extrusion processes used for aluminum profiles?

- There are several types of extrusion processes used for aluminum profiles, including direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion.

- Q: This question asks for the method to determine the amount of aluminum required for a construction project.

- <p>To calculate the weight of aluminum profiles needed for a building project, follow these steps: 1. Determine the length and cross-sectional area of each aluminum profile required. 2. Use the aluminum density, which is approximately 2.7 grams per cubic centimeter (g/cm鲁). 3. Multiply the volume (length 脳 cross-sectional area) by the density to get the weight of each profile. 4. Sum the weights of all profiles to get the total weight needed. Ensure to account for any additional material for joints, connections, and potential waste. It's also advisable to consult with an engineer or use specialized software for precise calculations tailored to your project's specific requirements.</p>

- Q: This question asks about the characteristics of aluminum profiles, specifically whether they are lightweight and easy to handle.

- <p>Yes, aluminum profiles are known for their lightweight nature and ease of handling. They are made from aluminum, which is a lightweight metal with a low density. This makes aluminum profiles ideal for applications where weight is a concern, such as in construction, automotive, and aerospace industries. Additionally, their lightweight characteristic also contributes to their ease of handling, as they can be easily maneuvered and installed without requiring heavy machinery or excessive manpower.</p>

Send your message to us

Extrusion Aluminum Profiles for Aluminium T-Profile Windows and Doors Installation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords