All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How does the choice of aluminum alloy affect the performance of structural profiles?

The choice of aluminum alloy significantly affects the performance of structural profiles. Different alloys have varying mechanical properties, such as strength, ductility, and corrosion resistance, which directly impact the structural integrity and overall performance of the profiles. For instance, high-strength alloys provide enhanced load-bearing capacity and durability, making them suitable for applications requiring structural strength, while corrosion-resistant alloys are better suited for environments prone to corrosion. Therefore, selecting the appropriate aluminum alloy is crucial to ensure optimal performance and longevity of structural profiles.

How do you choose the appropriate aluminum profile supplier or manufacturer for specific project requirements?

When choosing an aluminum profile supplier or manufacturer for specific project requirements, there are several factors to consider.

Firstly, it is important to assess the supplier or manufacturer's experience and expertise in producing aluminum profiles for similar projects. Look for a supplier with a proven track record in delivering high-quality products that meet the required specifications and standards.

Secondly, consider the supplier's production capabilities and capacity. Ensure that they have the necessary machinery, equipment, and resources to handle the volume and complexity of your project requirements.

Next, evaluate the supplier's product range and customization options. Look for a supplier that offers a wide variety of aluminum profiles and has the flexibility to customize them to your specific project needs. This will ensure that you can find the most suitable profile for your application.

Additionally, consider the supplier's quality control processes and certifications. Look for a supplier that follows stringent quality control measures and holds relevant certifications, such as ISO 9001, to ensure the consistency and reliability of their products.

Furthermore, it is important to consider the supplier's pricing and lead times. Obtain quotes from multiple suppliers and compare their prices while considering the overall value for money. Also, inquire about their lead times to ensure that they can meet your project's timeline.

Lastly, consider the supplier's customer service and support. A reliable supplier should provide excellent customer service, prompt communication, and assistance throughout the project, from initial inquiries to after-sales support.

By considering these factors and conducting thorough research, you can choose the appropriate aluminum profile supplier or manufacturer that best aligns with your specific project requirements.

What methods are used to anodize aluminum profiles for added protection?

There are several methods used to anodize aluminum profiles for added protection. The most common method is called sulfuric acid anodizing, where the aluminum is immersed in a sulfuric acid bath and an electric current is passed through it to create a protective oxide layer on the surface. Other methods include chromic acid anodizing and hardcoat anodizing, which involve different chemical solutions and processes to achieve varying levels of protection and surface hardness.

Wholesale Aluminum Profiles from supplier in Philippines

Whether you are looking for standard Aluminum Profiles or custom-designed solutions, we have the expertise to meet your requirements. Our team of highly skilled professionals is dedicated to delivering high-quality products that meet international standards.

We offer a wide range of Aluminum Profiles products, including but not limited to:

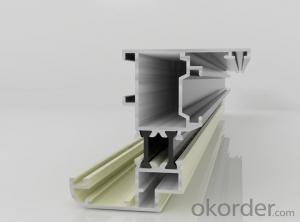

1. Aluminum Extrusions: We provide a variety of aluminum extrusions for different applications, such as windows, doors, curtain walls, and industrial profiles. Our extrusions are manufactured using advanced technology and high-quality materials to ensure durability and long-lasting performance.

2. Aluminum Profiles for Construction: We offer a comprehensive range of aluminum profiles for construction projects, including structural profiles, scaffolding systems, and formwork systems. These profiles are designed to meet the specific requirements of the construction industry, providing strength, stability, and ease of installation.

3. Aluminum Profiles for Industrial Applications: Our industrial profiles are designed to meet the demanding requirements of various industries, such as transportation, electronics, machinery, and automotive. These profiles are known for their excellent strength-to-weight ratio, corrosion resistance, and thermal conductivity.

4. Aluminum Profiles for Solar Energy Systems: We provide aluminum profiles specifically designed for solar energy systems, including solar panel frames, mounting systems, and support structures. These profiles are lightweight, durable, and corrosion-resistant, making them ideal for outdoor applications.

In addition to our wide range of Aluminum Profiles products, we also offer comprehensive services to assist you throughout the procurement process. Our experienced sales team is available to provide product information, quotations, and technical support. We aim to deliver excellent customer service and ensure that you have a seamless experience working with us.

Partner with us for all your Aluminum Profiles needs in the Philippines and let us help you find the optimal solutions for your projects. Contact us today for more information or to request a quotation.

We offer a wide range of Aluminum Profiles products, including but not limited to:

1. Aluminum Extrusions: We provide a variety of aluminum extrusions for different applications, such as windows, doors, curtain walls, and industrial profiles. Our extrusions are manufactured using advanced technology and high-quality materials to ensure durability and long-lasting performance.

2. Aluminum Profiles for Construction: We offer a comprehensive range of aluminum profiles for construction projects, including structural profiles, scaffolding systems, and formwork systems. These profiles are designed to meet the specific requirements of the construction industry, providing strength, stability, and ease of installation.

3. Aluminum Profiles for Industrial Applications: Our industrial profiles are designed to meet the demanding requirements of various industries, such as transportation, electronics, machinery, and automotive. These profiles are known for their excellent strength-to-weight ratio, corrosion resistance, and thermal conductivity.

4. Aluminum Profiles for Solar Energy Systems: We provide aluminum profiles specifically designed for solar energy systems, including solar panel frames, mounting systems, and support structures. These profiles are lightweight, durable, and corrosion-resistant, making them ideal for outdoor applications.

In addition to our wide range of Aluminum Profiles products, we also offer comprehensive services to assist you throughout the procurement process. Our experienced sales team is available to provide product information, quotations, and technical support. We aim to deliver excellent customer service and ensure that you have a seamless experience working with us.

Partner with us for all your Aluminum Profiles needs in the Philippines and let us help you find the optimal solutions for your projects. Contact us today for more information or to request a quotation.