All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

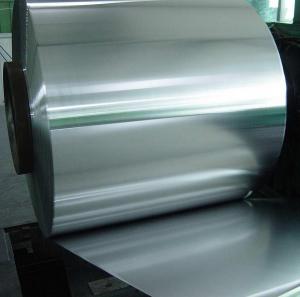

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How does the tin coating affect the machinability of electrolytic tinplate sheet?

The tin coating on electrolytic tinplate sheet improves its machinability by providing a smooth and lubricated surface. This reduces friction and wear during machining operations, resulting in enhanced cutting performance and increased tool life. Additionally, the tin coating helps to prevent the formation of burrs and chips, leading to a cleaner and more efficient machining process.

Are there any special handling requirements for electrolytic tinplate sheet during fabrication?

Yes, there are special handling requirements for electrolytic tinplate sheet during fabrication. It is important to handle the sheet with care to prevent any damage or scratching on the tin coating. Additionally, proper storage conditions should be maintained to avoid exposure to moisture or corrosive substances that can affect the quality of the tinplate.

What are the key differences between electrolytic tinplate sheet and other types of tinplate?

Electrolytic tinplate sheets differ from other types of tinplate primarily in the production process. Electrolytic tinplate is manufactured by electrolytic deposition of tin onto a steel base, which provides a smooth and uniform tin coating. This process ensures excellent corrosion resistance and adhesion of the tin layer. In contrast, other types of tinplate may use non-electrolytic methods like hot-dipping or electroplating, which can result in a less uniform tin coating and potentially lower corrosion resistance. Overall, electrolytic tinplate sheets are known for their high quality, consistent tin coating, and superior performance in various applications.

Can electrolytic tinplate sheet be used for cookie tins?

Yes, electrolytic tinplate sheet can be used for cookie tins.

Wholesale Electrolytic Tinplate Sheet from supplier in Philippines

Whether you are in the food and beverage industry, packaging industry, or any other industry that requires high-quality tinplate sheets, we have you covered. Our Electrolytic Tinplate Sheets are manufactured using advanced technology and meet international quality standards.

When you choose us as your supplier, you can expect excellent customer service and support throughout the entire process. Our dedicated sales team is available to assist you with any inquiries and provide you with competitive quotations. We understand the importance of timely delivery, and we strive to ensure that your orders are processed and delivered on time.

In addition to our sales support, we also offer technical assistance to help you make informed decisions about the type and specifications of tinplate sheets that best suit your requirements. Our team of experts is always ready to provide you with guidance and recommendations based on your specific needs.

As a subsidiary of CNBM, a Fortune Global 500 company, we have a strong foundation and reputation in the industry. You can trust us to deliver high-quality products and services consistently. We take pride in being your trusted platform for all your Electrolytic Tinplate Sheet needs in the Philippines.

Our one-stop procurement services ensure convenience and efficiency for our customers. From the initial inquiry to the final delivery, we handle all aspects of the procurement process, saving you time and effort. Our streamlined processes and extensive network allow us to source and supply a wide range of tinplate sheet products efficiently.

Furthermore, our years of market experience in the Philippines give us valuable insights and expertise that we can share with you. Whether you need advice on market trends, regulations, or project-specific requirements, we are here to support you every step of the way.

Choose us as your supplier of Electrolytic Tinplate Sheets in the Philippines, and experience the convenience, efficiency, and expertise that we offer. Contact us today to discuss your requirements and let us be your trusted partner in your tinplate sheet procurement journey.

When you choose us as your supplier, you can expect excellent customer service and support throughout the entire process. Our dedicated sales team is available to assist you with any inquiries and provide you with competitive quotations. We understand the importance of timely delivery, and we strive to ensure that your orders are processed and delivered on time.

In addition to our sales support, we also offer technical assistance to help you make informed decisions about the type and specifications of tinplate sheets that best suit your requirements. Our team of experts is always ready to provide you with guidance and recommendations based on your specific needs.

As a subsidiary of CNBM, a Fortune Global 500 company, we have a strong foundation and reputation in the industry. You can trust us to deliver high-quality products and services consistently. We take pride in being your trusted platform for all your Electrolytic Tinplate Sheet needs in the Philippines.

Our one-stop procurement services ensure convenience and efficiency for our customers. From the initial inquiry to the final delivery, we handle all aspects of the procurement process, saving you time and effort. Our streamlined processes and extensive network allow us to source and supply a wide range of tinplate sheet products efficiently.

Furthermore, our years of market experience in the Philippines give us valuable insights and expertise that we can share with you. Whether you need advice on market trends, regulations, or project-specific requirements, we are here to support you every step of the way.

Choose us as your supplier of Electrolytic Tinplate Sheets in the Philippines, and experience the convenience, efficiency, and expertise that we offer. Contact us today to discuss your requirements and let us be your trusted partner in your tinplate sheet procurement journey.