All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the surface finish options available for aluminum profiles, and how do they impact aesthetics and performance?

There are several surface finish options available for aluminum profiles, including anodizing, powder coating, and polishing.

Anodizing involves creating a protective layer on the surface of the aluminum through an electrochemical process. This finish not only enhances the appearance by providing a wide range of colors and finishes but also improves the corrosion resistance and durability of the profiles. Anodized profiles can withstand harsh environmental conditions and are less prone to fading or chipping over time.

Powder coating is another popular option that involves applying a dry powder onto the aluminum surface and then curing it using heat. This finish offers a wide variety of colors and textures, enhancing the aesthetics of the profiles. Additionally, powder coating provides excellent protection against corrosion, impact resistance, and durability, making it suitable for outdoor applications.

Polishing is a process that involves mechanically smoothing the surface of the aluminum profiles. This finish creates a reflective and shiny appearance, giving a premium and sophisticated look. While polishing enhances the aesthetic appeal, it may not provide the same level of protection against corrosion as anodizing or powder coating.

Overall, the choice of surface finish for aluminum profiles depends on the desired aesthetics and the intended application. Anodizing and powder coating improve both the appearance and performance, providing increased durability and corrosion resistance. On the other hand, polishing primarily focuses on aesthetics, giving a mirror-like finish but may lack the same level of protection.

What are the surface finish options available for aluminum profiles, and how do they impact performance?

There are multiple surface finish options available for aluminum profiles, including anodizing, powder coating, and mechanical finishes such as polishing or brushing.

Anodizing involves creating a protective oxide layer on the aluminum surface, providing increased durability, corrosion resistance, and a wide range of color options. It can also improve the profiles' resistance to UV radiation and abrasion.

Powder coating involves applying a layer of electrostatically charged powder onto the aluminum surface, which is then cured to form a durable and attractive finish. This option provides a wide variety of colors, excellent resistance to scratching, chipping, and fading, and enhanced corrosion resistance.

Mechanical finishes like polishing or brushing can create a smooth or textured surface respectively, enhancing the aesthetic appeal of the profiles. However, these finishes may have minimal impact on the performance of the profiles in terms of functionality or durability.

The choice of surface finish depends on the specific requirements of the application. Factors such as aesthetics, durability, corrosion resistance, and environmental conditions must be considered to determine the most suitable finish option.

What are the considerations for using aluminum profiles in outdoor signage?

There are several considerations for using aluminum profiles in outdoor signage. Firstly, aluminum is highly durable and weather-resistant, making it suitable for outdoor applications. It is resistant to corrosion, rust, and fading, ensuring the longevity of the signage. Secondly, aluminum profiles provide excellent structural strength, allowing for larger and more intricate designs. Additionally, aluminum is lightweight, making installation and transportation easier. Lastly, aluminum profiles offer versatility in terms of design options, as they can be easily customized and fabricated to meet specific requirements.

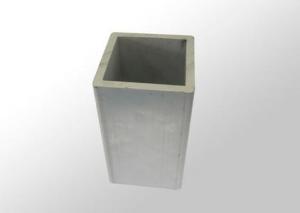

Wholesale Aluminum Profiles from supplier in Senegal

With our vast selection of Aluminum Profiles, we can cater to various industries and applications, including construction, architecture, industrial manufacturing, and transportation. Whether you require standard profiles or custom-made solutions, we have the capabilities to meet your specific requirements.

Our team of experts is dedicated to providing excellent customer service and technical support. We understand the importance of delivering accurate and timely quotes to help you make informed purchasing decisions. Our experienced staff can guide you through the selection process, ensuring that you choose the right profiles for your project.

As a subsidiary of CNBM, one of the world's largest building materials companies, we have access to a global network of suppliers, ensuring that we can offer competitive prices and high-quality products. We prioritize customer satisfaction and strive to exceed your expectations in terms of product quality, delivery, and overall service.

Whether you are working on a small-scale project or a large-scale development, we have the expertise and resources to meet your Aluminum Profiles needs in Senegal. Contact us today to discuss your requirements and let us be your trusted partner for all your procurement needs.

Our team of experts is dedicated to providing excellent customer service and technical support. We understand the importance of delivering accurate and timely quotes to help you make informed purchasing decisions. Our experienced staff can guide you through the selection process, ensuring that you choose the right profiles for your project.

As a subsidiary of CNBM, one of the world's largest building materials companies, we have access to a global network of suppliers, ensuring that we can offer competitive prices and high-quality products. We prioritize customer satisfaction and strive to exceed your expectations in terms of product quality, delivery, and overall service.

Whether you are working on a small-scale project or a large-scale development, we have the expertise and resources to meet your Aluminum Profiles needs in Senegal. Contact us today to discuss your requirements and let us be your trusted partner for all your procurement needs.