Aluminum Heatsink Extrusion Profiles for Windows and Doors Hot Selling Products

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Profile for Windows And Doors Hot Selling Products

Alloy | State | Tensile Strength δbMpa | Non-proportional Stretching Stress(δp0.2Mpa) | Stretching rate (δ%) | Pattern Thickness (mm) | HV | HW |

No Less Than | |||||||

6061 | T4/T6 | 180/265 | 110/245 | 16/8 | - | - | - |

6063 | T5/T6 | 160/205 | 110/180 | 8/8 | 0.8/- | 58/- | 8/- |

6063A | T5/T6 | 200,190/230,220 | 160,150/190,180 | 5,5/5,4 | 0.8,0.8/-,- | 65,65/-,- | 10,10/-,- |

2. Application of Aluminum Profile for Windows And Doors Hot Selling Products

wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors,windows…

3. Feature of Aluminum Profile for Windows And Doors Hot Selling Products

Surface Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Decoration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mochenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

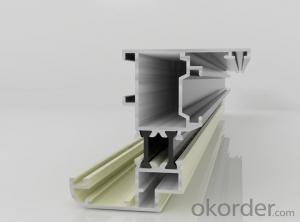

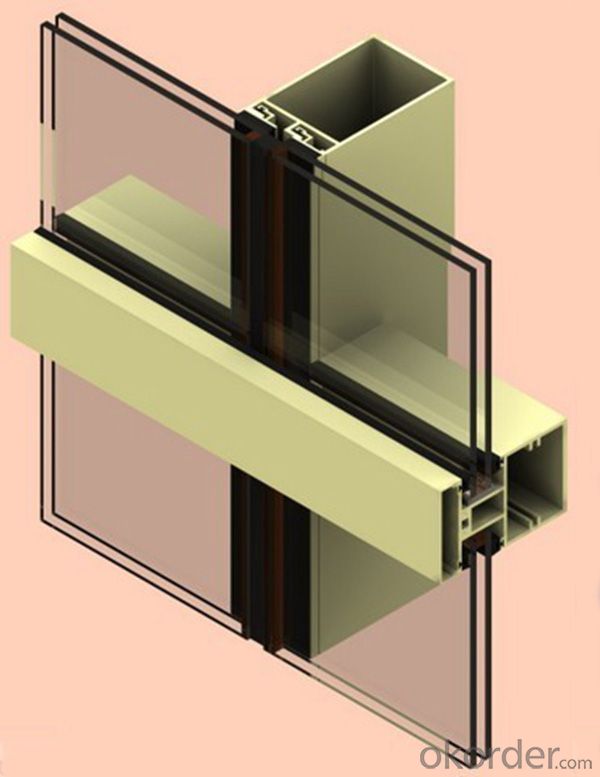

5. Image of Aluminum Profile for Windows And Doors Hot Selling Products

6. Package and shipping of Aluminum Extrusion Profile for Curtain Wall Made in China

First, plastic cloth with drying agent inside; Second, Pearl Wool; Third, wooden cases with dry agent, fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

Question 1: What is your MOQ?

We accept one ton per type for an order. But the detail we could negotiate.

Question 2: What is your normal terms of payment?

We always trade with you by T/T. But we also accept the L/C as you require.

Question 3: How many kinds of the surface treatment we can choose?

You could choose different color of powder coated. Anodized of black. matte silver, nature, champagne, bronze color. Mill finished. Wooden finished and printed.etc.

Question 4: Can you supply OEM services?

We offer OEM services for 17 years.

Question 5: How many days for opening the mould?

Normally about 10 days.According to the difficulty of your drawing.

Question 6: Can i choose the package what i want?

Yes, of course. We offer various kinds of package.e.g.PE foam. Shrink film. Wrapping paper.

But we would give you professional suggestion of package.

- Q: This question asks for methods to avoid corrosion on aluminum profiles during the installation process.

- <p>To prevent corrosion on aluminum profiles during installation, follow these steps: Use high-quality aluminum that has a protective oxide layer. Ensure the installation environment is dry and clean. Avoid contact with corrosive substances like acids or alkalis. Apply a protective coating or sealant if the profiles will be exposed to harsh environments. Use stainless steel or corrosion-resistant fasteners. Regularly inspect and clean the profiles to remove any dirt or debris that could lead to corrosion. Proper installation techniques and maintenance can significantly reduce the risk of corrosion on aluminum profiles.</p>

- Q: The original aluminum is silver, but now the market has black, yellow and green, aluminum radiator, radiator is the color what are formed by oxidation of different colors, what are the benefits of it, are used in the above types of products?

- In this process, there is no difference for several different color film properties, the only difference is that the surface of different colors can increase the appearance of the product, can choose different colors according to the requirements of different products.

- Q: What are the different surface polishing options for aluminum profiles?

- There are several surface polishing options available for aluminum profiles, each offering different levels of shine and finish. Some of the commonly used methods are: 1. Mechanical Polishing: This process involves using abrasives and polishing compounds to physically remove surface imperfections and create a smooth, reflective finish. It can be done manually or with the help of automated machines. Mechanical polishing is effective in achieving a high level of shine but may require multiple steps and careful attention to detail. 2. Chemical Polishing: This technique involves the use of chemical solutions to dissolve a thin layer of aluminum, resulting in a smoother and more polished surface. Chemical polishing is often used for large-scale production as it can be done relatively quickly and uniformly. However, it may not provide the same level of shine as mechanical polishing. 3. Electrolytic Polishing: This method utilizes an electric current to remove surface imperfections and create a polished finish. The aluminum profile acts as the anode, and a conductive material serves as the cathode. Electrolytic polishing is known for its ability to produce a mirror-like finish with excellent precision and uniformity. 4. Anodizing: Although not a polishing method per se, anodizing is a popular surface treatment for aluminum profiles. It involves creating a protective oxide layer on the surface of the metal through an electrochemical process. Anodizing can enhance the appearance of aluminum profiles by providing a smooth, colored, or clear finish, while also improving their durability and corrosion resistance. The choice of surface polishing option depends on the desired level of shine, the complexity of the profile's design, and the intended application. Each method has its advantages and limitations, and it is important to consider factors such as cost, time, and quality requirements when selecting the most suitable option.

- Q: 3030 aluminum profiles, can be used in outdoor snow exposure environment?

- This refers to the 3030 heavy aluminum profiles. General aluminum profile manufacturers will make a number of their own products,

- Q: Are aluminum profiles suitable for indoor applications with high humidity?

- Aluminum profiles are indeed a fitting option for indoor applications in environments with high humidity. Due to its non-corrosive nature and impressive moisture resistance, aluminum is an excellent choice. It remains unaffected by rust or deterioration when exposed to moisture, ensuring its longevity and durability. Moreover, aluminum profiles can be enhanced with protective finishes like anodizing or powder coating, which further fortifies their resistance against humidity, preventing any potential harm. Thus, aluminum profiles emerge as a dependable and appropriate choice for indoor applications in high humidity environments.

- Q: Are aluminum profiles compatible with glass or other glazing materials?

- Glass and other glazing materials can be used with aluminum profiles. Aluminum is a popular choice for window and door frames because it is strong, durable, and versatile. Combining aluminum with glass allows for the creation of stylish and functional windows, doors, and architectural elements. Aluminum profiles are specifically designed to securely hold and support glass panels, ensuring a safe and stable glazing system. Furthermore, aluminum profiles can also be used with polycarbonate or acrylic sheets, giving flexibility in design and construction. In summary, aluminum profiles are highly compatible with glass and various glazing materials, making them a dependable option for contemporary architectural projects.

- Q: Can aluminum profiles be used for rooftop installations?

- Yes, aluminum profiles can be used for rooftop installations. Aluminum is a lightweight and durable material that is resistant to corrosion, making it suitable for outdoor applications such as rooftop installations. It is commonly used in the construction industry for various purposes, including the framing and support structures of rooftop installations.

- Q: What is a pouring type heat insulation aluminum profile?

- Pouring type thermal insulation aluminum profile is put into the liquid insulation curing Aluminum Alloy section casting trough and resection, Aluminum Alloy section casting trough Pro bridge connecting through the broken metal insulation material Aluminum Alloy insulation two combined composite material.

- Q: Are aluminum profiles suitable for constructing energy-efficient buildings?

- <p>Yes, aluminum profiles can be used to create energy-efficient building designs. They are lightweight, strong, and have excellent thermal conductivity, which can be utilized to design structures with reduced heat transfer, thereby improving energy efficiency. Aluminum profiles can also be used in combination with insulating materials to enhance thermal insulation. Their recyclability and low maintenance requirements contribute to sustainability, further supporting energy-efficient construction practices.</p>

- Q: The user is asking if it's possible to use recycled aluminum to create new aluminum profiles.

- <p>Yes, recycled aluminum can be used to produce new aluminum profiles. The process of recycling aluminum is energy-efficient and environmentally friendly, as it requires significantly less energy compared to producing aluminum from raw materials. Recycled aluminum maintains the same properties as new aluminum, making it suitable for manufacturing various aluminum profiles. The recycling process typically involves melting the aluminum, which can then be cast into new shapes and forms, including profiles for construction, automotive, and other industries. This not only conserves resources but also reduces waste and carbon emissions.</p>

Send your message to us

Aluminum Heatsink Extrusion Profiles for Windows and Doors Hot Selling Products

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords