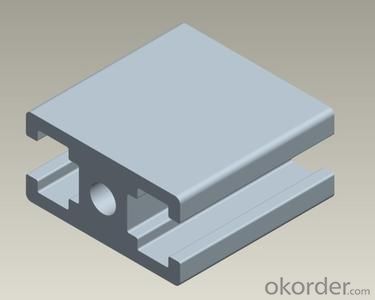

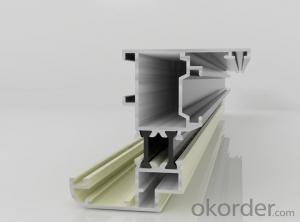

Aluminum Heat Sink Extrusion Profiles for Decoration

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetal with appearance ranging from silvery to dull gray,depending on the surface roughness. It is nonmagnetic and does not easilyignite. A fresh film of aluminium serves as a good reflector (approximately92%) of visible light and an excellent reflector (as much as98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffnessof steel. It iseasily machined,cast, drawn and extruded.

Alu Profile:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

FAQ:

1. What is the form of payment?

Normally 30% TT, L/C at sight

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Guangzhou/Shenzhen port

4. Delivery time?

15-20 days after client’s deposit

- Q: This question asks for methods to prevent moisture from entering aluminum profiles during the installation process.

- <p>To prevent moisture from getting into aluminum profiles during installation, ensure proper sealing and insulation. Use high-quality weatherstripping and sealants around joints and connections. Install moisture barriers or vapor retarders where necessary, especially in areas prone to high humidity. Keep profiles dry during handling and storage, and avoid installing in wet conditions. Regularly inspect and maintain the profiles to identify and address any potential moisture issues early.</p>

- Q: What are the different surface protection options available for aluminum profiles?

- Various surface protection options are available for aluminum profiles, depending on specific requirements and applications. 1. Anodizing is a commonly used surface treatment for aluminum profiles. It involves an electrochemical process that creates a protective oxide layer on the surface. Anodizing offers excellent corrosion resistance, durability, and can enhance the profiles' aesthetic appearance with a variety of colors. 2. Another popular option is powder coating. This process applies a dry powder to the profiles' surface through electrostatics, which is then cured under heat to form a protective coating. Powder coating provides durability, scratch resistance, and comes in various colors and finishes. 3. Painting is a traditional method for protecting aluminum profiles. It involves applying a liquid paint coating that safeguards against corrosion, UV radiation, and enhances appearance. Painting offers a wide range of colors and finishes to meet aesthetic requirements. 4. Clear coating is commonly used when preserving the natural appearance of the aluminum profiles is desired. This coating forms a transparent film on the surface, protecting against oxidation, scratches, and other environmental factors while showcasing the metallic look. 5. Film coating, also known as protective film or peelable coating, is a temporary option. A thin layer of film is applied to protect the profiles during transportation, handling, or installation. The film can be easily peeled off after installation, leaving a clean surface. 6. Mechanical finishing techniques such as brushing, polishing, or sandblasting can improve the surface appearance of aluminum profiles. These methods can achieve desired texture, gloss level, or remove imperfections. While they do not provide long-term protection, they can be combined with other options for enhanced aesthetics. Overall, choosing the appropriate surface protection option for aluminum profiles depends on factors like intended application, desired aesthetics, durability requirements, and cost considerations. Selecting the most suitable option ensures the profiles' longevity and performance.

- Q: What is the aluminum section table?

- Table characteristics: working table, using aluminum material customized special products and durable, the breakage rate of the lowest! For quality of aluminum profiles, I strongly recommend item aluminum, aluminum fortunately which do not know, do not know how the quality of aluminum is our common problem. Here is a little experience for me to share with you.

- Q: Explain how aluminum profiles contribute to the energy efficiency of a building.

- <p>Aluminum profiles significantly enhance the energy efficiency of a building through several mechanisms. They are lightweight yet strong, reducing the overall weight of the structure and the energy required for construction. Their excellent thermal conductivity allows for efficient heat transfer, which can be managed with proper insulation to reduce heat loss. Aluminum profiles also facilitate better window and door sealing, minimizing drafts and heat leakage. Additionally, their high reflectivity can help in reflecting solar heat, reducing the need for cooling. Lastly, aluminum profiles can be used in the construction of solar panels and other renewable energy systems, further contributing to a building's energy efficiency.</p>

- Q: Are aluminum profiles suitable for food processing applications?

- Yes, aluminum profiles are suitable for food processing applications. Aluminum is a lightweight and durable material that is resistant to corrosion, making it ideal for use in industries such as food processing where hygiene and cleanliness are crucial. Additionally, aluminum profiles can be easily cleaned and maintained, ensuring the safety and quality of the food being processed.

- Q: What are the reasons for the slow down of aluminum extrusion press?

- Check the overflow valve alone pressure is not fast enough, if not fast enough, there may be a damper plug, remove, try again

- Q: Are aluminum profiles suitable for use as exterior wall materials?

- <p>Yes, aluminum profiles can be used for exterior walls. They are known for their durability, resistance to weathering, and low maintenance requirements. Aluminum is lightweight, strong, and can be easily shaped into various designs. It also has excellent resistance to corrosion, making it ideal for outdoor applications. Additionally, aluminum profiles can be powder coated or anodized for enhanced protection and aesthetic appeal, allowing them to blend well with different architectural styles.</p>

- Q: What does "3030W" W mean for European standard industrial aluminum?

- This refers to the 3030 heavy aluminum profiles. General aluminum profile manufacturers will make a number of their own products, European standard 3030 series has a variety of specifications, such as Jing Teng aluminum European standard 3030R, referring to the European standard 3030 fan, 3030G refers to the 3030 GB profiles. In short, look at your own needs,

- Q: This question asks for a list of various aluminum profiles that are specifically designed or used for roofing systems in regions with cold climates.

- <p>In cold climates, aluminum profiles for roofing systems are selected for their durability, strength, and resistance to harsh weather conditions. Common types include: 1. Standing Seam Profiles: These are popular for their weather-tightness and resistance to snow and ice. 2. Trapezoidal Profiles: Known for their strength and ability to handle heavy snow loads. 3. Box Rib Profiles: These provide excellent structural integrity and are suitable for areas with high wind uplift. 4. Snap-Lock Profiles: Easy to install and offer good resistance to snow and ice. 5. Corrugated Profiles: Provide a traditional look while being cost-effective and offering good drainage. 6. Panel Rib Profiles: These are designed for long spans and can withstand heavy snowfall. Each profile has specific applications and advantages, and the choice depends on the specific roofing requirements and local climate conditions.</p>

- Q: What are the advantages and disadvantages of the use of magnesium profiles compared with aluminum profiles?

- 3 oxidation of metals: the periodic table clearly shows that magnesium alloy is more easily oxidized than aluminum alloy.4 manufacturing cost Description: because magnesium alloy is a lively metal, so manufacturing equipment and environment have higher requirements, leading to high manufacturing costs, production of bicycle frame cost performance is far less than aluminum alloy frame.

Send your message to us

Aluminum Heat Sink Extrusion Profiles for Decoration

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords