Grc Decoration

Grc Decoration Related Searches

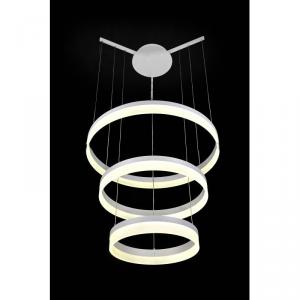

Store Decoration Children S Garden Decorations Lighted Christmas Decorations Outdoor Xmas Decorations Accessories For Lighting Decorative Lights Indoor Vintage Pendant Lighting Decorative Interior Doors Decorative Solar Lantern Chandelier Fixture Parts Office Lighting Fixtures Led Lighting Accessories Exterior Light Post Fixtures Lighting And Accessories Fluorescent Lamp Fixture Kitchen Ceiling Fixtures Outdoor Ceiling Light Fixtures Outside Post Lighting Fixtures Lamp Light Fixture Parts Rustic Interior Lighting Leather Accessories Bathroom Wares Parts For Light Fixtures Replacement Light Fixture Parts Small Ceiling Light Fixtures Bathroom Ceiling Light Fixtures Hallway Ceiling Light Fixtures prison light fixtures Dimmable Ceiling Light Fixtures Indoor Spotlight FixtureGrc Decoration Supplier & Manufacturer from China

Grc Decoration, which stands for Glass Fiber Reinforced Concrete, is a versatile construction material known for its durability and aesthetic appeal. This product is crafted using a combination of cement, sand, and glass fibers, resulting in a lightweight yet strong material that can be molded into various shapes and designs. Grc Decoration is widely used in both interior and exterior applications, such as decorative facades, architectural moldings, and garden ornaments, offering a cost-effective and visually striking alternative to traditional materials. Okorder.com, a reputable wholesale supplier, boasts a large inventory of Grc Decoration products, catering to the diverse needs of architects, contractors, and homeowners. With their extensive range, Okorder.com ensures that customers can find the perfect Grc Decoration pieces for their projects, whether it's for a residential or commercial setting.Hot Products