Lighting And Accessories

Lighting And Accessories Related Searches

Accessories For Lighting Car Lighting Accessories Led Lighting Accessories Liners And Covers Automatic Lighting Light Accessories For Cars Leather Accessories Stage Lighting And Sound Heating & Cooling Stage Sound And Lighting Front Lighting Parts For Light Fixtures Yarns And Fibres Light Fitting Components Outdoor Lighting Systems Replacement Light Fixture Parts Home Spotlights Lighting Car Interiors Accessories Lamp Light Fixture Parts Heating And Air Conditioning Parts Network Switches And Routers Street Light Maintenance Heating Cooling And Ventilation Escalator And Elevator Heating And Cooling Repair Decorative Lights Indoor Office Lighting Fixtures Commercial Lights Indoor Light Roofing Materials Outdoor Kitchen LightingLighting And Accessories Supplier & Manufacturer from China

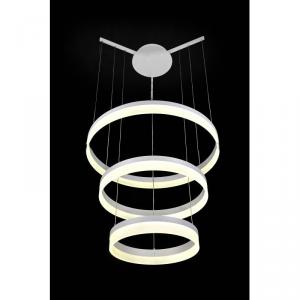

Lighting and Accessories encompass a wide range of products that cater to various lighting needs, from residential to commercial applications. These products include LED lights, chandeliers, lamps, and other decorative fixtures that enhance the ambiance and functionality of any space. They are designed to provide optimal illumination while also adding aesthetic appeal to the environment.The application and usage scenarios of Lighting and Accessories are vast, as they can be found in homes, offices, retail stores, and public spaces. They are essential in creating a comfortable and inviting atmosphere, as well as ensuring safety and visibility in various settings. Whether it's for general lighting, task lighting, or accent lighting, these products play a crucial role in enhancing the overall experience and efficiency of any space.

Okorder.com is a leading wholesale supplier of Lighting and Accessories, boasting a large inventory that caters to the diverse needs of customers worldwide. With a commitment to quality and customer satisfaction, Okorder.com offers a comprehensive selection of products at competitive prices, making it the go-to destination for lighting solutions and accessories.

Hot Products