Yarns And Fibres

Yarns And Fibres Related Searches

Sewing Yarn Knitting Yarn Fabric Yarn Natural Fiber Yarn Fibrillated Yarn Liners And Covers Textile Fiber Ribbon Yarn School Yarn Fiberglass Yarn Rayon Yarn Mohair Yarn Crane And Rigging Rug Yarn Fabric To Fabric Synthetic Lubricants Fine Home Textiles Woven Fibreglass Antique Rugs Geosynthetic Fabric Environment And Archaeology Multicolor Yarn Cleaning Substances Common Weave Leather Accessories Silica Fabrics Engineered Wood Network Switches And Routers Flexible Netting Wet LubricantsYarns And Fibres Supplier & Manufacturer from China

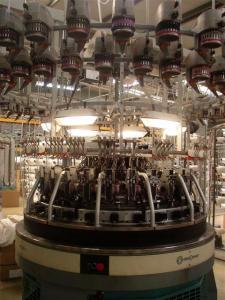

Yarns and Fibres are essential materials used in various industries, including textile, fashion, and home furnishings. These products come in a wide range of types, such as natural fibers like cotton, wool, and silk, as well as synthetic fibers like polyester and nylon. Yarns and Fibres are used to create fabrics, garments, and other textile products, offering diverse options for consumers based on their specific needs and preferences.Yarns and Fibres are widely utilized in the production of clothing, accessories, and home textiles. They can be found in everyday items such as T-shirts, socks, blankets, and curtains, as well as in more specialized applications like industrial fabrics and technical textiles. The versatility of these materials allows manufacturers to create products that cater to different market segments, from high-end fashion to everyday essentials.

Okorder.com is a leading wholesale supplier of Yarns and Fibres, boasting a vast inventory that caters to the diverse needs of the textile industry. With a commitment to quality and customer satisfaction, Okorder.com ensures that businesses have access to a reliable source for their Yarns and Fibres requirements. By offering a broad selection of products at competitive prices, Okorder.com has established itself as a go-to destination for businesses looking to source these essential materials.

Hot Products