Modular Aluminum Profiles Anodizing with Different Colors

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

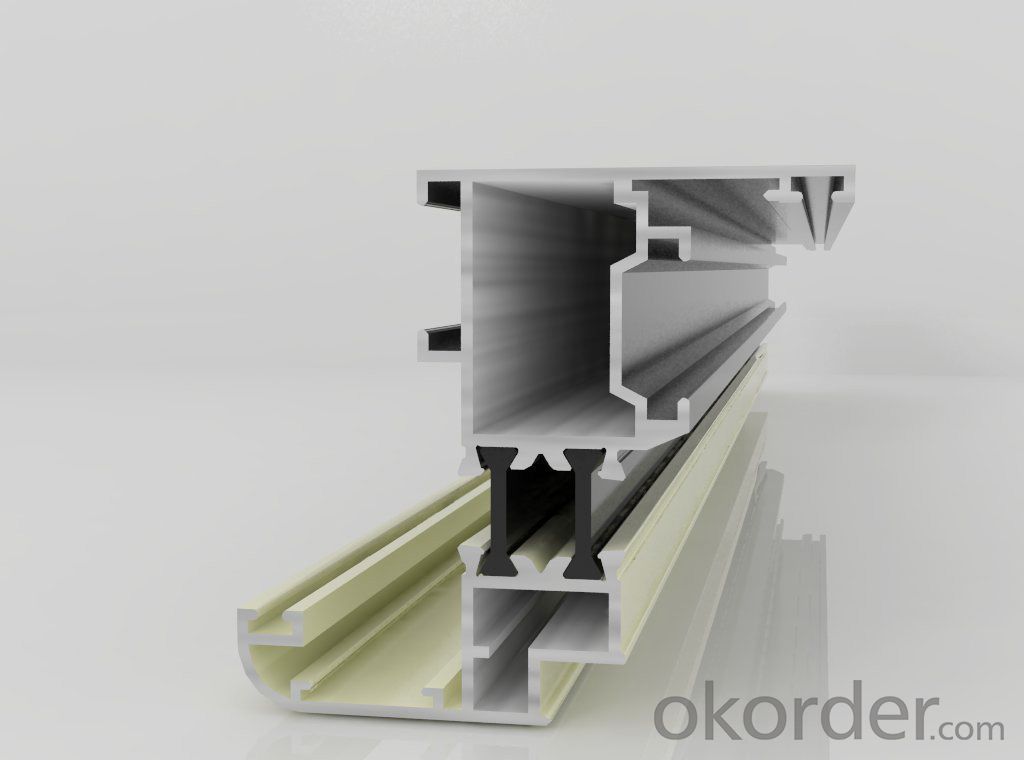

1.Structure of Aluminium Profile Anodizing with Different Color Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminium Profile Anodizing with Different Color:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

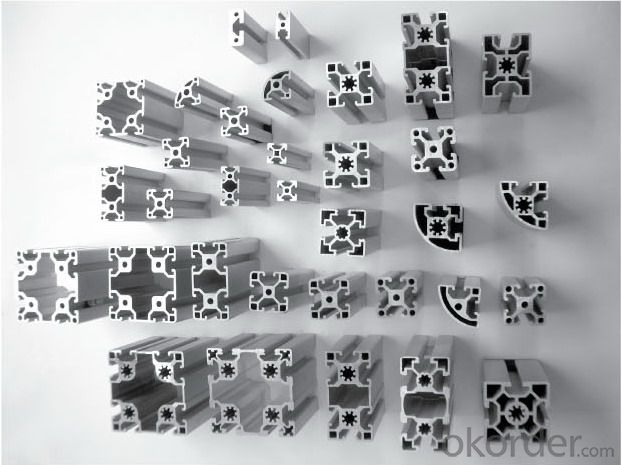

3.Aluminium Profile Anodizing with Different Color Images:

4.Aluminium Profile Anodizing with Different Color Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: This question asks for a method to determine whether the building materials include aluminum profiles.

- <p>To determine if your current building uses aluminum profiles, you can start by examining the visible structural components such as window frames, door frames, and support beams. Look for the characteristic silvery color and smooth finish of aluminum. You can also check the building's documentation or blueprints, if available, for material specifications. Consulting with the building's architect or engineer can provide definitive information. In some cases, a non-destructive testing method like ultrasonic testing might be used to identify materials without damaging the structure.</p>

- Q: Are aluminum profiles suitable for use in roofing systems in areas with high wind conditions?

- <p>Yes, aluminum profiles can be used for roofing systems in windy regions. Aluminum is a lightweight and durable material that can withstand high winds. It is often used in the construction of roofing systems because of its strength and resistance to corrosion. Additionally, aluminum profiles can be designed to meet specific wind load requirements, making them suitable for areas prone to strong winds. However, the design and installation of the roofing system must be done correctly to ensure it can handle the wind forces.</p>

- Q: This question asks for a variety of green building materials that incorporate recycled aluminum profiles, indicating an interest in sustainable construction practices.

- <p>Recycled aluminum profiles are used in various green building materials to promote sustainability. These include: 1) Window and door frames, known for their durability and energy efficiency. 2) Facade systems, which provide a lightweight and strong alternative to traditional materials. 3) Structural components, such as beams and columns, offering strength with less material. 4) Roofing materials, which can be lightweight and resistant to corrosion. 5) Modular building systems, which use prefabricated aluminum components for quick assembly. 6) Fencing and railings, offering a low-maintenance option. 7) Solar panel supports, combining recycled aluminum with renewable energy technology. These materials reduce waste, save energy, and lower carbon emissions in construction.</p>

- Q: Can aluminum profiles be used in the construction of modular healthcare facilities?

- Yes, aluminum profiles can be used in the construction of modular healthcare facilities. Aluminum profiles are lightweight, durable, and have excellent structural properties, making them an ideal choice for constructing modular healthcare facilities. These profiles can be easily fabricated and assembled, allowing for quick and efficient construction of healthcare modules. Additionally, aluminum is resistant to corrosion, which is particularly important in healthcare facilities where hygiene is crucial. It also has good thermal and electrical conductivity, allowing for efficient energy management and integration of various electrical systems in the modular healthcare facility. Overall, aluminum profiles offer numerous advantages and are a suitable material for the construction of modular healthcare facilities.

- Q: What are the advantages of using aluminum profiles in the defense industry?

- There are several advantages of using aluminum profiles in the defense industry. Firstly, aluminum profiles offer high strength-to-weight ratio, making them ideal for applications requiring lightweight yet durable components. This allows for the development of lighter military vehicles, aircraft, and other defense equipment, which ultimately enhances mobility and fuel efficiency. Secondly, aluminum profiles possess excellent corrosion resistance properties, ensuring the longevity and reliability of defense systems even in harsh environments. This is particularly crucial for military equipment that operates in various weather conditions and may be exposed to saltwater or corrosive agents. Additionally, aluminum profiles can be easily machined and fabricated into complex shapes, allowing for customization and innovative designs, which can optimize performance and functionality. These profiles also offer good electrical conductivity, making them suitable for applications requiring electrical grounding or electromagnetic shielding. Lastly, aluminum is a highly recyclable material, aligning with sustainability goals. This not only reduces waste but also supports the defense industry's efforts towards environmental stewardship. Overall, the advantages of using aluminum profiles in the defense industry include lightweight strength, corrosion resistance, versatility in design, electrical conductivity, and sustainability.

- Q: Including the element parameters, the price and the difference between 6063, what is the use and so on!How about 6060 100/ meters? How much is the strength? How much is the price more than 6063?

- It has many valuable features: 1. heat treatment, high impact toughness, plasticity of missing insensitive.2. has excellent heat, can be squeezed into a high speed complex structure. The hollow thin wall. Various profiles or forged into the complex structure of the forging, quenching temperature range quenching, low sensitivity, extrusion and forging after stripping, as long as the temperature is higher than the quenching temperature. The quenching method available water or water in thin walled parts (6.

- Q: Explain the various uses of aluminum profiles in architectural design.

- <p>Aluminum profiles have a wide range of applications in architectural design due to their strength, durability, and versatility. They are commonly used for curtain walls, which provide a sleek and modern appearance while offering thermal insulation. Aluminum profiles are also used in window and door frames for their lightweight and strong properties, enhancing security and energy efficiency. They are integral in the construction of sun shading systems and louvers, which help control light and heat in buildings. Additionally, aluminum profiles are used in structural components like beams and columns, as well as in decorative elements such as facades and balustrades, offering both functional and aesthetic benefits.</p>

- Q: This question asks about the various types of fasteners that are used to secure aluminum profiles in construction projects.

- <p>In construction, several types of fasteners are used to secure aluminum profiles. These include: 1. Bolts and Nuts: Commonly used for joining aluminum profiles, they provide a strong and secure connection. 2. Rivets: These are used for permanent connections and are ideal for load-bearing applications. 3. Screws: Self-tapping screws are often used for joining aluminum profiles without the need for pre-drilling. 4. Adhesives: Structural adhesives can be used for bonding aluminum profiles together, providing a strong and durable joint. 5. Clamps and Brackets: These are used to temporarily or permanently secure aluminum profiles in place. 6. Connectors and Brackets: Specifically designed for aluminum profiles, these connectors provide a secure and aesthetically pleasing joint. Each type of fastener has its own advantages and is chosen based on the specific requirements of the construction project.</p>

- Q: How do you prevent galling or seizing with aluminum profiles?

- To prevent galling or seizing with aluminum profiles, it is important to use proper lubrication. Applying a suitable lubricant, such as a specialized anti-seize compound or a lubricating oil, can significantly reduce friction and prevent the surfaces from sticking together. Additionally, ensuring that the aluminum profiles are clean and free from any contaminants or debris can also help prevent galling or seizing.

- Q: Are aluminum profiles suitable for use in industrial settings like shelving and storage systems?

- <p>Yes, aluminum profiles are indeed suitable for industrial applications such as shelving and storage systems. They offer several advantages including high strength-to-weight ratio, corrosion resistance, and ease of assembly. Aluminum profiles are lightweight, which makes them ideal for constructing sturdy yet lightweight shelving and storage solutions. Their resistance to corrosion means they can withstand harsh industrial environments without rusting. Additionally, the modular nature of aluminum profiles allows for customizable designs that can be easily adjusted or reconfigured to meet changing storage needs.</p>

Send your message to us

Modular Aluminum Profiles Anodizing with Different Colors

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords