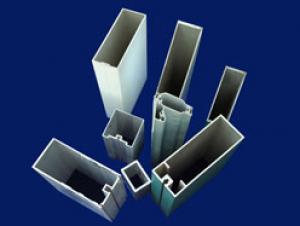

Aluminum Profiles - Anodized and Powder Coated Aluminum Profile

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft, durable, lightweight, ductileand malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible lightand an excellent reflector (as much as 98%) of medium and far infraredradiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the densityand stiffness of steel. It is easily machined,cast, drawn and extruded.

Features:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

- Q: What are the different packaging options available for aluminum profiles?

- There are several different packaging options available for aluminum profiles, depending on the specific requirements and preferences of the manufacturers or customers. 1. Bundles: Aluminum profiles can be packaged in bundles, where multiple profiles are stacked together and secured with strapping or shrink wrap. This option is commonly used for larger profiles or when shipping in bulk. 2. Boxes: Smaller aluminum profiles can be packaged in boxes, which provide protection during transportation and storage. The profiles are usually placed in individual compartments within the box to prevent damage from rubbing against each other. 3. Tubes: Some aluminum profiles, especially those with a circular shape, can be packaged in tubes. These tubes are made of durable materials such as cardboard or plastic and provide excellent protection from scratches or dents. 4. Pallets: Aluminum profiles can also be packaged on pallets, especially when shipping in large quantities. The profiles are stacked on top of each other on a pallet and secured with stretch wrap or straps. This option facilitates easy handling and transportation using forklifts or pallet jacks. 5. Customized Packaging: In certain cases, manufacturers or customers may require customized packaging solutions for specific aluminum profiles. This can include foam inserts, protective film, or other specialized packaging materials to ensure maximum protection during transit. It is important to consider factors such as profile size, weight, fragility, and transportation requirements when choosing the appropriate packaging option for aluminum profiles. Additionally, compliance with industry standards and regulations should be taken into account to ensure safe delivery to the end-users.

- Q: This question asks for an explanation of the various types of aluminum profiles that are specifically used in the manufacturing and construction of windows and doors.

- <p>Aluminum profiles for windows and doors come in various types, each serving specific functions and designs. Common types include: 1) Casement profiles, used for side frames and meeting stiles in casement windows; 2) Mullion profiles, for vertical and horizontal structural members in window walls; 3) Transom profiles, used in the top or bottom of windows to support glazing; 4) Sash profiles, forming the main frame of the window sash; 5) Threshold profiles, used at the bottom of doors for weather sealing; 6) Header profiles, supporting the top of a door or window opening; and 7) Specialty profiles, designed for specific architectural needs like corner posts or decorative elements. Each profile is engineered for strength, durability, and compatibility with glazing and浜旈噾閰嶄欢.</p>

- Q: What are the aluminum profile manufacturers in Jiangsu?

- For the choice of aluminum profiles, here are a few suggestions for you to refer to:First: very cheap, do not chooseAs follows: the cost of industrial aluminum material = the spot price of aluminum ingot, the processing cost of extrusion aluminum material, the freight of packing material. These are transparent, the cost of aluminum profiles are similar, significantly lower than the market price, the first possibility: the weight per meter less; second: aluminum is the use of recycled materials; third: material loss amplification (not according to the actual sales amount of meters).Second: only understand the sale material supplier does not chooseExplain as follows: preparing goods, recruit a few operator, big online promotion can be opened. Those who are often hurt are our buyers. Miss wiring mostly do not know how to use, only know the unit price. How to use to meet customer needs; how to make the most cost-effective; in different venues that kind of connection is the best; these are they can not answer accurately. Only know the cheapest and recommended profile connection the cheapest; this connection is the lowest cost, but the cost of artificial, a connection is the weakest, aluminum convenience wouldn't be reflected, and will bring much trouble for the future reconstruction. But the wiring girl will push it one way.Third: in production of aluminium supplierExplain as follows: in the production of aluminum suppliers, are generally engaged in this industry for more than 10 years, and their users have very rich experience, have a good understanding and knowledge of the quality and performance of products, suitable for the requirement of the customers will recommend price is a good product, choose a convenient and practical accessories.

- Q: Aluminum bending die, iron must be used, what iron should be used, specifically what brand?

- General production of aluminum alloy is H13, die steel, if stretched or squeezed, most are carbide. I work in the production of aluminum profiles

- Q: What are the different surface engraving or etching techniques for aluminum profiles?

- Aluminum profiles can be engraved or etched using various techniques, each with its own advantages and outcomes. Some commonly employed methods are as follows: 1. Chemical Etching: By selectively removing the top layer of the aluminum profile using chemicals, this technique enables precise and intricate designs to be etched onto the surface, making it ideal for decorative purposes. 2. Laser Engraving: Employing a high-powered laser beam to vaporize the aluminum surface, this approach yields a permanent etching. It allows for exceptional precision, making it suitable for detailed designs and logos. 3. Mechanical Engraving: This technique involves physically engraving the aluminum profile's surface using rotary cutters or diamond-tipped tools. It is frequently used in industrial applications, such as marking product codes or serial numbers. 4. Electrochemical Etching: By utilizing an electric current and an electrolyte solution, this method etches the aluminum surface. It is often used to create durable and legible markings, such as product labels or identification codes. 5. Sandblasting: This process entails directing abrasive particles at high speed onto the aluminum surface, removing its top layer. The result is a textured or frosted appearance, often employed for decorative purposes or to achieve a matte finish. 6. Acid Etching: Acid etching involves the use of an acid solution to selectively remove the top layer of the aluminum surface. It is commonly employed to create a matte or satin finish, as well as patterns or textures on the profile. These techniques present a wide array of options for aluminum profiles, allowing for customization, branding, or functional purposes. The selection of a specific technique depends on factors such as the desired design, level of detail, durability requirements, and intended application of the aluminum profile.

- Q: Aluminum profile CAD drawings

- Aluminum section, designers can directly call the drawing, wide application and machine Association, electronic equipment, instrumentation equipment, aluminum plating process, which belongs to the coating technology it is pre plating and electroplating process steps to increase on the basis of conventional Ti process, aluminum is the process of the aqueous solution of salt and hydrochloric acid in the plating the activation of chemical treatment; electroplating bath composition including nickel sulfate, nickel chloride, boric acid, twelve sodium lauryl sulfate, saccharin, brightener, this process has the advantages of simple, practical and good effect etc.

- Q: Where is the aluminum profile market in Nanjing? Specific address, bus route

- Before inadvertently arrived, as if on the South Fengtai Road, and now do not know where.

- Q: Explain if aluminum profiles can be utilized in constructing energy-efficient building systems and if so, how they contribute to energy efficiency.

- <p>Yes, aluminum profiles can be used to create energy-efficient building systems. They are lightweight yet strong, which reduces the energy required for construction. Aluminum profiles also have excellent thermal conductivity, allowing them to be used in double-glazed windows and doors, improving insulation and reducing heat loss. Additionally, aluminum can be easily recycled, reducing the energy needed for new materials. Their high reflectivity can also help in reducing heat absorption, further contributing to energy efficiency.</p>

- Q: I would like to know where Urumqi has industrial aluminum profiles, such as 3030, 4040, 3060 aluminum, etc., note that industrial aluminum, not doors and windows, aluminum profiles, the difference between the two very large!

- And shares in the east railway station there, the east railway station and then go one Station Road (near the North Main Road) can see.

- Q: What are the weatherproofing properties of aluminum profiles?

- Due to their inherent characteristics and manufacturing processes, aluminum profiles possess excellent weatherproofing properties. This is due to aluminum being a naturally corrosion-resistant material, allowing it to endure exposure to different weather conditions without deteriorating or rusting. It forms a protective layer of oxide on its surface, serving as an additional barrier against moisture and preventing further corrosion. Moreover, various weatherproofing techniques can further enhance aluminum profiles. Anodizing is a common method where the aluminum surface undergoes an electrolytic process to create a thicker and more durable oxide layer. This not only improves weather resistance but also enhances resistance to scratching and wear. Furthermore, aluminum profiles can be coated with protective finishes like powder coating or liquid paint. These coatings not only add aesthetic appeal but also provide an extra layer of protection against UV radiation, moisture, and other weather elements. Powder coating, in particular, offers exceptional durability and resistance to fading, chipping, and cracking. Additionally, aluminum profiles can be designed to incorporate weatherproof features such as gaskets, seals, and thermal breaks. These elements establish a tight seal between the profile and other building components, preventing water infiltration, air leakage, and thermal transfer. They contribute to maintaining a comfortable indoor environment, reducing energy consumption, and enhancing the overall weatherproofing performance of the aluminum profiles. In summary, the weatherproofing properties of aluminum profiles make them a popular choice for a wide range of applications, including windows, doors, curtain walls, roofing systems, and outdoor furniture. Their ability to withstand harsh weather conditions, resistance to corrosion, and availability of protective coatings make them a dependable and long-lasting option for both residential and commercial projects.

Send your message to us

Aluminum Profiles - Anodized and Powder Coated Aluminum Profile

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords