CC Aluminum Sheet for Embossed Anti-Skidding - Aluminum Profiles for Glass

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 3400 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

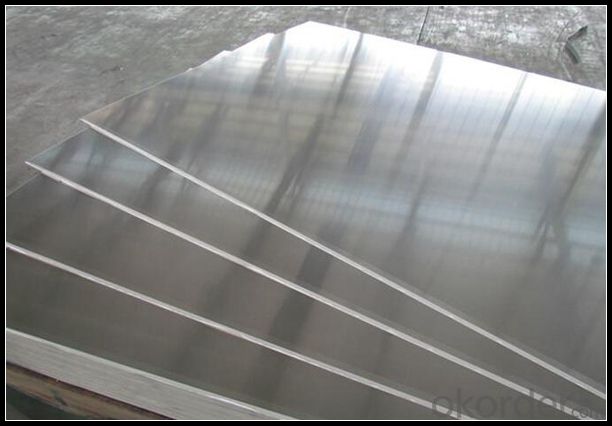

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? |

A: Normally it would be 40days after received your deposit. |

Q: Can you provide free samples? |

A: Yes, free samples will be sent to you on freight at destination. |

Q: Can I get your latest catalogue? |

A: Yes, it will be sent to you in no time. |

Q: What is the MOQ? |

A: 3 tons |

Q: What are your payment terms? |

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: What are the various finishes or coatings that can be applied to aluminum profiles to enhance their appearance, durability, or functionality?

- <p>Aluminum profiles can be coated with a variety of options to improve their aesthetic appeal, corrosion resistance, and performance. These include anodizing, which creates a protective oxide layer; powder coating, offering a wide range of colors and textures; electrophoretic coating, known for its smooth finish; and thermal spraying, which involves applying a coating through a high-velocity flame. Other options are painting, which can be done in various colors, and polishing, which gives a shiny finish. Each coating option has its specific benefits and applications, depending on the requirements of the project.</p>

- Q: Can aluminum profiles be used in curtain wall systems?

- Indeed, curtain wall systems have the capacity to incorporate aluminum profiles. Such systems usually consist of lightweight materials that provide structural support while simultaneously permitting ample natural light to infiltrate a building. The utilization of aluminum in curtain wall systems is quite prevalent owing to its robustness, endurance, and versatility. Aluminum showcases exceptional resistance against corrosion, rendering it suitable for outdoor applications. Furthermore, aluminum profiles can be readily fabricated into diverse shapes and sizes, thus enabling flexibility in design and assembly. The lightweight nature of aluminum also facilitates easier and more cost-effective installation. In summary, aluminum profiles offer an optimal solution for curtain wall systems, delivering both aesthetic allure and functional efficacy.

- Q: Are aluminum profiles suitable for swimming pool enclosures?

- Yes, aluminum profiles are suitable for swimming pool enclosures. Aluminum is a durable and lightweight material that is resistant to corrosion, making it ideal for outdoor applications like swimming pool enclosures. It offers strength and stability while also being low maintenance and easy to clean. Additionally, aluminum profiles can be customized to fit specific design requirements, providing a wide range of options for swimming pool enclosure construction.

- Q: Can aluminum profiles be recycled and reused for interior wall cladding purposes?

- <p>Yes, aluminum profiles can be recycled and reused in interior wall cladding applications. Aluminum is a highly recyclable material, and its recycling process does not degrade its properties, making it an excellent choice for sustainable construction. Recycled aluminum profiles can be used to create new wall cladding systems, reducing waste and the environmental impact of mining and processing new aluminum. This practice not only conserves natural resources but also contributes to energy savings and a lower carbon footprint.</p>

- Q: Is it feasible to recycle aluminum profiles economically and in significant quantities?

- <p>Yes, aluminum profiles can be recycled at a reasonable cost and volume. Recycling aluminum is more cost-effective than mining and refining new aluminum from bauxite. The process requires less energy, which reduces costs. Additionally, aluminum has a high recycling rate, with about 75% of all aluminum ever produced still in use today. This indicates that aluminum recycling is both economically viable and can be done in significant volumes, contributing to sustainability and waste reduction.</p>

- Q: What are the various materials that can be combined with aluminum profiles in construction or manufacturing?

- <p>Aluminum profiles can be combined with a variety of materials to enhance their functionality and durability. Common materials include steel for added strength, plastics for lightweight components, and various types of glass for transparency and aesthetics. They can also be paired with rubber or silicone seals for weatherproofing, and wood for a warmer, more natural aesthetic. Additionally, aluminum profiles are often used with other metals such as copper or brass for electrical conductivity or corrosion resistance. The choice of material depends on the specific application, desired properties, and design requirements.</p>

- Q: What are the different surface sandblasting options for aluminum profiles?

- There are several surface sandblasting options available for aluminum profiles, each providing a unique finish and level of abrasiveness. 1. Fine sandblasting: This option involves using fine-grain sand or abrasive materials to gently remove surface imperfections and create a smooth finish on the aluminum profile. It is commonly used when a polished or satin appearance is desired. 2. Coarse sandblasting: Coarse sandblasting utilizes larger-grain sand or abrasive materials to provide a more rugged texture on the aluminum surface. This option is often chosen to create a matte or textured finish, which can help to hide scratches or other blemishes. 3. Glass bead blasting: In this method, small glass beads are propelled at high speed onto the aluminum profile's surface. This process is typically used to achieve a uniform and aesthetically pleasing matte finish. Glass bead blasting is also commonly employed when a certain level of reflectivity is desired. 4. Walnut shell blasting: This option involves using ground walnut shells as the blasting media. Walnut shell blasting is a more gentle technique compared to sandblasting, making it suitable for delicate aluminum profiles. It can effectively remove contaminants and provide a clean, smooth finish. 5. Shot peening: Shot peening is a specialized sandblasting process that involves bombarding the aluminum profile with small metal shots or pellets. This technique is primarily utilized to increase the strength and resistance to fatigue of the aluminum surface, rather than altering its appearance. It is important to consider the specific requirements and desired outcome when choosing a surface sandblasting option for aluminum profiles. Consulting with professionals in the field can help determine the most suitable method based on the desired finish, level of abrasiveness, and the aluminum profile's properties.

- Q: What are the top 20 Chinese architectural aluminum profiles?

- 14, Fujian public security Aluminum Co. Ltd.15, Zhejiang pillars of new material Limited by Share Ltd16, Lear aluminum industry Limited by Share Ltd17 、 Ming emperor Aluminum Industry Co., Ltd.18, Guangdong silver100 innovation Aluminum Co. Ltd.19 、 Qingyuan Asia Aluminum Co., Ltd.20 、 Guanghan Sichuan Sanxing Aluminium Industry Co., Ltd.

- Q: What are the different cross-sectional shapes available for aluminum profiles?

- Aluminum profiles come in various cross-sectional shapes, each with its own distinct characteristics and uses. Some commonly encountered shapes are: 1. Square profiles: These have equal sides and 90-degree corners, making them suitable for applications that require strength and stability, such as frames and supports. 2. Rectangular profiles: With unequal sides and 90-degree corners, these profiles offer a larger surface area and increased strength, making them popular in construction and transportation industries. 3. Round profiles: These profiles have a circular cross-section and are favored for their smooth appearance and excellent strength-to-weight ratio. They are commonly found in furniture, automotive parts, and lighting fixtures. 4. T-slot profiles: These profiles feature a T-shaped groove on one or more sides, allowing for easy assembly of components using specialized fasteners. They are widely used in machine frames, workstations, and robotics. 5. L-shaped profiles: These profiles have two perpendicular sides forming a 90-degree angle, making them ideal for corner joints, braces, and edges. They provide structural support and stability in various applications. 6. U-shaped profiles: These profiles have a concave shape resembling the letter "U" and are often used for trim, edging, and protective barriers. They provide a neat and finished look. 7. Custom shapes: In addition to the standard shapes mentioned above, aluminum profiles can also be customized to meet specific design requirements. This flexibility allows for the creation of unique profiles tailored to specific applications or industries. In summary, the availability of different cross-sectional shapes for aluminum profiles gives designers and engineers a wide range of options. This ensures compatibility with various applications and enables efficient and effective use of this versatile material.

- Q: How to use aluminum profile on the side of roller conveyor?

- Aluminum profile inside 1 cm thick lining board, our unit of assembly line is like that

Send your message to us

CC Aluminum Sheet for Embossed Anti-Skidding - Aluminum Profiles for Glass

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 3400 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords