All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

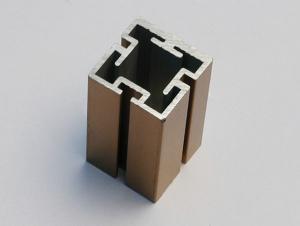

What factors influence the cost of aluminum profiles in manufacturing?

There are several factors that influence the cost of aluminum profiles in manufacturing. Some of the key factors include the cost of raw materials, such as the price of aluminum itself, as well as any additional alloying elements or coatings used. The complexity of the profile design and the desired specifications also play a role, as more intricate and precise profiles may require specialized machinery and processes, leading to increased costs. Furthermore, factors like the quantity of profiles being produced, economies of scale, and the overall demand for aluminum profiles in the market can also impact the cost.

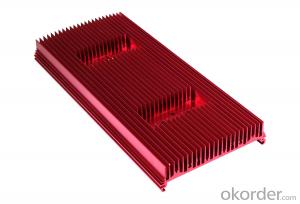

What are the environmental benefits of using aluminum profiles in the production of renewable energy systems?

The environmental benefits of using aluminum profiles in the production of renewable energy systems are threefold. First, aluminum is a highly recyclable material, meaning that the profiles can be easily reclaimed and reused, reducing the need for raw material extraction and minimizing waste generation. Second, aluminum is lightweight compared to other metals, reducing the energy required for transportation and installation of renewable energy systems. Lastly, aluminum has a low carbon footprint, as it requires significantly less energy to produce compared to other metals, resulting in lower greenhouse gas emissions during the manufacturing process. Overall, using aluminum profiles in renewable energy systems promotes resource efficiency, reduces carbon emissions, and supports sustainable development.

How are aluminum profiles used in the production of conveyors and material handling equipment?

Aluminum profiles are commonly used in the production of conveyors and material handling equipment due to their lightweight yet durable nature. These profiles are often used to construct the frames, supports, and guide rails of the conveyor systems. The versatility of aluminum profiles allows for easy customization and quick assembly, making them a preferred choice for manufacturers. Additionally, aluminum's corrosion resistance properties make it suitable for use in various industries, including food processing and pharmaceuticals.

How do aluminum profiles contribute to sustainability and recycling efforts?

Aluminum profiles contribute to sustainability and recycling efforts in several ways. Firstly, aluminum is a highly recyclable material, which means that aluminum profiles can be easily recycled and reused without losing their quality. This reduces the need for extracting and producing new aluminum, leading to significant energy savings and reduced greenhouse gas emissions.

Additionally, aluminum profiles are lightweight yet durable, making them an ideal material for various applications such as construction, transportation, and consumer goods. The lightweight nature of aluminum profiles helps in reducing the overall weight of products, leading to lower energy consumption during transportation and improved fuel efficiency in vehicles.

Moreover, aluminum profiles have a long lifespan and require minimal maintenance, reducing the need for frequent replacement. This not only saves resources but also reduces waste generation. At the end of their useful life, aluminum profiles can be recycled again, making them a truly sustainable choice.

Overall, the use of aluminum profiles promotes a circular economy by minimizing resource extraction, energy consumption, and waste generation, thus contributing significantly to sustainability and recycling efforts.

Wholesale Aluminum Profiles from supplier in Honduras

Whether you are looking for standard profiles or customized solutions, we have the capability to meet your specific requirements. Our Aluminum Profiles are manufactured using high-quality materials and advanced technology, ensuring durability and precision.

Our team of experts is dedicated to providing excellent customer service and support. From assisting you with product selection and quotation to technical guidance, we aim to make your procurement process seamless and efficient.

Being a subsidiary of CNBM, we have access to a vast network of resources and expertise. This allows us to offer competitive pricing, reliable delivery, and a wide range of options to choose from. We understand the importance of timely delivery and strive to ensure that your orders reach you on time.

With our years of experience in the Honduran market, we have developed strong relationships with local suppliers and manufacturers. This enables us to provide valuable insights and recommendations for your projects, ensuring that you make informed decisions.

Whether you are involved in construction, automotive, or any other industry that requires Aluminum Profiles, we are here to meet your needs. Contact us today to discuss your requirements and let us help you find the perfect solution for your projects.

Our team of experts is dedicated to providing excellent customer service and support. From assisting you with product selection and quotation to technical guidance, we aim to make your procurement process seamless and efficient.

Being a subsidiary of CNBM, we have access to a vast network of resources and expertise. This allows us to offer competitive pricing, reliable delivery, and a wide range of options to choose from. We understand the importance of timely delivery and strive to ensure that your orders reach you on time.

With our years of experience in the Honduran market, we have developed strong relationships with local suppliers and manufacturers. This enables us to provide valuable insights and recommendations for your projects, ensuring that you make informed decisions.

Whether you are involved in construction, automotive, or any other industry that requires Aluminum Profiles, we are here to meet your needs. Contact us today to discuss your requirements and let us help you find the perfect solution for your projects.