All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the different methods for joining and connecting aluminum profiles for structural applications?

Some common methods for joining and connecting aluminum profiles for structural applications include welding, screw fastening, adhesive bonding, and using specialized connectors or brackets. Welding involves melting the aluminum profiles together using heat, while screw fastening involves using screws or bolts to hold the profiles together. Adhesive bonding involves using a strong adhesive to attach the profiles, while specialized connectors or brackets are designed to specifically connect aluminum profiles. Each method has its own advantages and considerations depending on the specific application and desired strength and flexibility requirements.

What is the role of aluminum profiles in the construction of stadiums and sports facilities?

Aluminum profiles play a crucial role in the construction of stadiums and sports facilities. They are widely used for various purposes such as framing, structural support, and design elements. Aluminum profiles offer high strength-to-weight ratio, corrosion resistance, and durability, making them an ideal choice for these projects. They are used in the construction of grandstands, roofs, facades, and other architectural features, providing stability and aesthetic appeal. Additionally, aluminum profiles can be easily customized and fabricated to meet specific design requirements, allowing for flexibility and innovation in stadium construction. Overall, aluminum profiles contribute to the overall safety, functionality, and visual appeal of stadiums and sports facilities.

How do you attach accessories and components to aluminum profiles?

Accessories and components can be attached to aluminum profiles using various methods such as T-slot nuts, bolts, screws, or specialized connectors designed for aluminum extrusions. These accessories are typically inserted into the T-slots or grooves on the profile and then secured using appropriate fasteners. The flexibility and versatility of aluminum profiles allow for easy attachment and adjustment of components, making them widely used in various industries for constructing modular structures and frameworks.

Wholesale Aluminum Profiles from supplier in Denmark

Our team is committed to delivering top-notch customer service and ensuring a seamless procurement experience for our clients. Whether you need standard Aluminum Profiles or customized solutions, we have you covered. Our sales representatives are knowledgeable and can assist you in finding the right products for your specific requirements.

Additionally, we provide comprehensive quotation services, ensuring competitive pricing and transparent cost breakdowns. Our technical support team is also available to answer any questions or provide guidance on installation and maintenance.

Being a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This allows us to stay up-to-date with industry trends and provide valuable insights that can benefit your projects.

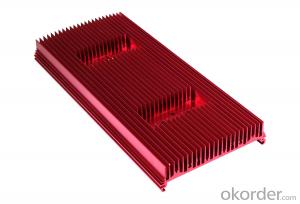

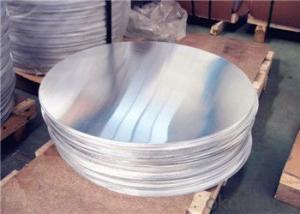

We take pride in the quality and reliability of our Aluminum Profiles. We work closely with trusted manufacturers to ensure that our products meet the highest standards. Our rigorous quality control processes guarantee that you receive durable and long-lasting profiles that will exceed your expectations.

Customer satisfaction is our priority, and we strive to exceed your expectations at every step of the procurement process. Contact us today to discover how our Aluminum Profiles can enhance your projects in Denmark.

Additionally, we provide comprehensive quotation services, ensuring competitive pricing and transparent cost breakdowns. Our technical support team is also available to answer any questions or provide guidance on installation and maintenance.

Being a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This allows us to stay up-to-date with industry trends and provide valuable insights that can benefit your projects.

We take pride in the quality and reliability of our Aluminum Profiles. We work closely with trusted manufacturers to ensure that our products meet the highest standards. Our rigorous quality control processes guarantee that you receive durable and long-lasting profiles that will exceed your expectations.

Customer satisfaction is our priority, and we strive to exceed your expectations at every step of the procurement process. Contact us today to discover how our Aluminum Profiles can enhance your projects in Denmark.