All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How do you select the appropriate aluminum profile supplier or manufacturer for specific project requirements and industry standards?

When selecting an aluminum profile supplier or manufacturer for specific project requirements and industry standards, it is important to consider several factors. Firstly, assess the supplier's or manufacturer's experience and expertise in producing aluminum profiles for your specific industry. Look for their track record and customer reviews to ensure their reliability and quality.

Next, consider the supplier's or manufacturer's production capabilities and capacity. Ensure they can meet your project's requirements in terms of quantity, delivery time, and customization options.

Additionally, it is crucial to verify if the supplier or manufacturer complies with industry standards and certifications. Look for certifications like ISO 9001, ISO 14001, and OHSAS 18001, which indicate their commitment to quality, environmental management, and occupational health and safety.

Furthermore, evaluate the supplier's or manufacturer's communication and customer service. A responsive and cooperative supplier will be better equipped to address any concerns or modifications during the project.

Lastly, compare prices and obtain quotes from multiple suppliers or manufacturers to ensure competitive pricing without compromising on quality. By considering these factors, you can select an appropriate aluminum profile supplier or manufacturer that meets your specific project requirements and industry standards.

What are the design considerations when creating complex shapes and structures using aluminum profiles?

When creating complex shapes and structures using aluminum profiles, there are several design considerations to take into account.

Firstly, it is important to consider the load-bearing capacity of the aluminum profiles. This involves determining the maximum weight and stress that the structure will be subjected to, and selecting profiles with the appropriate strength and thickness to support these loads.

Secondly, the connection methods between the aluminum profiles must be carefully chosen. Whether using mechanical fasteners, welding, or adhesive bonding, the connections should provide sufficient strength and stability to ensure the integrity of the structure.

Another consideration is the overall aesthetics and appearance of the design. Aluminum profiles offer a wide range of shapes and finishes, so selecting the right profile design and surface treatment can enhance the visual appeal of the structure.

Additionally, the manufacturing and assembly process should be considered. Complex shapes and structures may require specialized equipment or techniques for fabrication and assembly. It is essential to ensure that the chosen design can be efficiently produced and assembled without compromising quality.

Lastly, the environmental conditions in which the structure will be used should be taken into account. Aluminum profiles offer excellent corrosion resistance, but in certain environments such as marine or industrial settings, additional protective measures may be required to prevent deterioration.

Overall, careful consideration of load-bearing capacity, connection methods, aesthetics, manufacturing process, and environmental factors are crucial when designing complex shapes and structures using aluminum profiles.

How do aluminum profiles contribute to energy-efficient transportation systems?

Aluminum profiles contribute to energy-efficient transportation systems by being lightweight yet strong, which helps reduce the overall weight of vehicles. This reduction in weight results in improved fuel efficiency and reduced emissions. Additionally, the use of aluminum profiles in the construction of vehicles allows for better aerodynamics, further enhancing their energy efficiency.

Wholesale Aluminum Profiles from supplier in Venezuela

We understand the importance of quality and reliability when it comes to Aluminum Profiles, which is why we source our products from trusted manufacturers. Our Aluminum Profiles are made from high-quality materials, ensuring durability and strength in various applications.

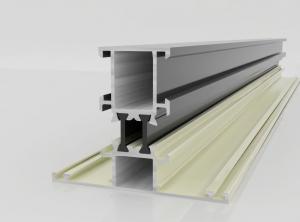

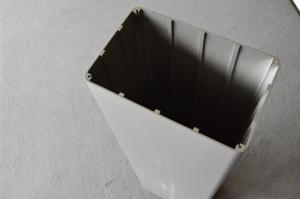

Whether you require Aluminum Profiles for construction, transportation, or industrial purposes, our team of experts is dedicated to providing personalized solutions that meet your specific requirements. We offer a wide range of profiles, including extruded profiles, custom profiles, and standard profiles, available in different shapes, sizes, and finishes.

At our company, we prioritize customer satisfaction, and we strive to deliver exceptional services at every stage of the process. From initial inquiries and quotations to technical support and after-sales service, our team is committed to ensuring a seamless experience for our customers.

To further enhance our services, we have established strong partnerships with logistics providers, enabling us to offer efficient and timely delivery to any location in Venezuela. Additionally, our dedicated customer service team is available to address any queries or concerns you may have, providing prompt assistance throughout your project.

Partner with us for your Aluminum Profiles needs in Venezuela, and benefit from our extensive product range, industry expertise, and commitment to customer satisfaction. Together, we can achieve excellence in your projects.

Whether you require Aluminum Profiles for construction, transportation, or industrial purposes, our team of experts is dedicated to providing personalized solutions that meet your specific requirements. We offer a wide range of profiles, including extruded profiles, custom profiles, and standard profiles, available in different shapes, sizes, and finishes.

At our company, we prioritize customer satisfaction, and we strive to deliver exceptional services at every stage of the process. From initial inquiries and quotations to technical support and after-sales service, our team is committed to ensuring a seamless experience for our customers.

To further enhance our services, we have established strong partnerships with logistics providers, enabling us to offer efficient and timely delivery to any location in Venezuela. Additionally, our dedicated customer service team is available to address any queries or concerns you may have, providing prompt assistance throughout your project.

Partner with us for your Aluminum Profiles needs in Venezuela, and benefit from our extensive product range, industry expertise, and commitment to customer satisfaction. Together, we can achieve excellence in your projects.