All Categories

- - Steel Wire Rod

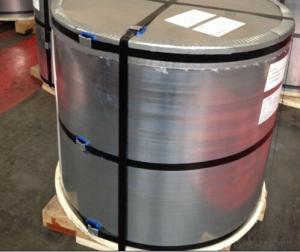

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

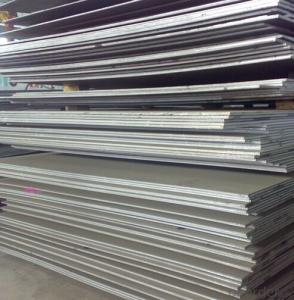

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What is the role of cold-rolled steel in the manufacturing of electrical enclosures?

The role of cold-rolled steel in the manufacturing of electrical enclosures is to provide a strong and durable material that can withstand the rigors of industrial and commercial environments. Cold-rolled steel is specifically chosen for its excellent mechanical properties, such as high tensile strength and resistance to corrosion. It allows for precise shaping and forming, ensuring the enclosure meets the required specifications and dimensions. Additionally, the smooth and uniform surface finish of cold-rolled steel enhances the aesthetic appeal of the enclosure. Overall, cold-rolled steel plays a vital role in providing the necessary structural integrity and protection for electrical components within enclosures.

How does cold-rolled steel perform in marine environments?

Cold-rolled steel performs well in marine environments due to its superior corrosion resistance, strength, and durability. The process of cold rolling enhances the steel's ability to withstand the harsh conditions of saltwater, preventing corrosion and rusting. Additionally, its high tensile strength ensures structural integrity, making it suitable for various marine applications such as shipbuilding, offshore platforms, and marine equipment.

What are the environmental benefits of using cold-rolled steel in construction?

Using cold-rolled steel in construction offers several environmental benefits. Firstly, it requires less energy during the manufacturing process compared to hot-rolled steel, resulting in reduced greenhouse gas emissions. Additionally, cold-rolled steel is more durable and corrosion-resistant, leading to longer-lasting structures that require less maintenance and replacement, thus reducing waste and resource consumption. Furthermore, cold-rolled steel is often made from recycled material, promoting the circular economy and reducing the demand for virgin resources. Overall, choosing cold-rolled steel in construction helps minimize environmental impact and contributes to sustainable building practices.

Wholesale Cold Rolled Steel from supplier in Denmark

Whether you require Cold Rolled Steel for construction, manufacturing, or any other industry in Denmark, we have the expertise to meet your specific needs. Our product range includes various grades and finishes of Cold Rolled Steel, ensuring that we can provide the right solution for your requirements.

In addition to our high-quality products, we offer dedicated sales and technical support services. Our knowledgeable team can assist you in selecting the appropriate Cold Rolled Steel products for your project, providing guidance and recommendations based on your specifications and budget. We can also provide detailed quotations, ensuring transparency and accuracy in pricing.

As a subsidiary of CNBM, one of the largest building materials companies in the world, we have access to a vast network of resources and partnerships. This enables us to offer competitive pricing, reliable supply chains, and efficient logistics for our customers in Denmark.

Furthermore, our extensive market experience in Denmark allows us to provide valuable insights and expertise. We understand the local regulations, industry standards, and customer preferences in Denmark, ensuring that we can deliver tailored solutions that meet your specific requirements.

By choosing our company as your supplier of Cold Rolled Steel in Denmark, you can expect a seamless and efficient procurement experience. We are committed to delivering high-quality products, exceptional customer service, and reliable support throughout your project.

Contact us today to discuss your Cold Rolled Steel needs in Denmark and let us provide you with the best solutions for your business.

In addition to our high-quality products, we offer dedicated sales and technical support services. Our knowledgeable team can assist you in selecting the appropriate Cold Rolled Steel products for your project, providing guidance and recommendations based on your specifications and budget. We can also provide detailed quotations, ensuring transparency and accuracy in pricing.

As a subsidiary of CNBM, one of the largest building materials companies in the world, we have access to a vast network of resources and partnerships. This enables us to offer competitive pricing, reliable supply chains, and efficient logistics for our customers in Denmark.

Furthermore, our extensive market experience in Denmark allows us to provide valuable insights and expertise. We understand the local regulations, industry standards, and customer preferences in Denmark, ensuring that we can deliver tailored solutions that meet your specific requirements.

By choosing our company as your supplier of Cold Rolled Steel in Denmark, you can expect a seamless and efficient procurement experience. We are committed to delivering high-quality products, exceptional customer service, and reliable support throughout your project.

Contact us today to discuss your Cold Rolled Steel needs in Denmark and let us provide you with the best solutions for your business.