All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

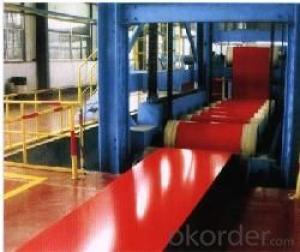

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How are steel strips used in the medical industry?

Steel strips are commonly used in the medical industry for various applications such as surgical instruments, orthopedic implants, and medical devices. The high strength and durability of steel make it suitable for these purposes, ensuring precision, reliability, and longevity in medical equipment. Additionally, steel strips are often used in the production of medical tubing and catheters, providing the necessary flexibility and resilience required for these applications.

What are the challenges and requirements for producing precision steel strips?

Producing precision steel strips involves several challenges and requirements. Firstly, ensuring the dimensional accuracy of the strips is crucial, as even slight variations can impact the performance and functionality of the end product. This requires precise control over the production processes, such as rolling, annealing, and slitting, to maintain tight tolerances.

Secondly, achieving the desired surface quality is essential. Any surface imperfections, such as scratches or defects, can affect the strip's appearance, corrosion resistance, and mechanical properties. Therefore, stringent quality control measures, including surface inspection and polishing techniques, are necessary throughout the production cycle.

Thirdly, maintaining consistent mechanical properties across the entire length of the strip is vital for applications that require uniform strength and ductility. This requires careful control of the chemical composition, heat treatment processes, and mechanical testing to ensure consistent properties throughout the material.

Additionally, producing precision steel strips often involves meeting specific requirements for strength, hardness, flexibility, and surface coatings, depending on the intended application. Understanding and fulfilling these requirements necessitate close collaboration with customers and thorough knowledge of the end-use industries.

Lastly, to produce precision steel strips efficiently, having advanced manufacturing equipment, skilled personnel, and an effective quality management system is essential. Continual improvement in process control, waste reduction, and customer feedback integration are crucial for meeting the challenges and ensuring high-quality products.

How do steel strips contribute to the development of durable and long-lasting components for military and defense applications?

Steel strips contribute to the development of durable and long-lasting components for military and defense applications through their exceptional strength, hardness, and resistance to wear and corrosion. These strips are often utilized as the primary material in the construction of various components such as armor plates, vehicle frames, and ammunition casings. Their high tensile strength ensures that these components can withstand extreme forces and impacts, providing enhanced protection to military personnel and equipment. Moreover, steel strips' durability and resistance to corrosion help maintain the integrity of these components over extended periods, making them reliable and long-lasting assets in critical defense operations.

What is the width range of steel strips?

The width range of steel strips can vary depending on the specific application, but it typically ranges from a few millimeters to several hundred millimeters.

Wholesale Steel Strips from supplier in Guinea Bissau

We are a Steel Strips supplier serving the Guinea Bissau, mainly engaged in the sale, quotation, and technical support services of various Steel Strips products in the Guinea Bissau region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Steel Strips procurement services in the Guinea Bissau. Not only do we have a wide range of Steel Strips products, but after years of market development in the Guinea Bissau, we can also provide valuable experience for your projects.