All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

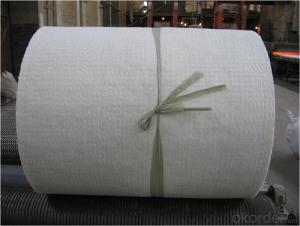

- - Ceramic Fiber Products

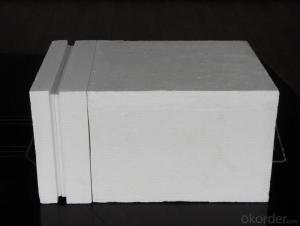

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Monolithic RefractoriesView More

Ceramic Fiber ProductsView More

Refractory BricksView More

Raw Materials For RefractoryView More

Q & A

How do refractory materials deteriorate over time?

Refractory materials deteriorate over time due to various factors such as thermal cycling, chemical reactions, mechanical stress, and environmental conditions. The repeated exposure to high temperatures causes expansion and contraction, leading to the formation of cracks and spalling. Chemical reactions with the substances being processed can also corrode the refractory material. Additionally, mechanical stress from thermal shocks and physical impacts weakens the structure, further contributing to its deterioration. Environmental factors like humidity, aggressive gases, and slag can also degrade the refractory material, reducing its performance and lifespan.

What are the refractory materials used in foundries?

Refractory materials commonly used in foundries include silica, alumina, magnesia, and chromite. These materials have high melting points and excellent resistance to heat, allowing them to withstand the extreme temperatures found in foundry operations.

What is the role of refractory materials in industrial processes?

Refractory materials play a crucial role in industrial processes as they are designed to withstand high temperatures, harsh chemical environments, and intense mechanical stress. These materials are used to line furnaces, kilns, reactors, and other equipment where extreme heat resistance is required. They help to maintain thermal insulation, prevent heat loss, and protect the structural integrity of the equipment. Additionally, refractory materials also resist chemical corrosion, erosion, and abrasion, ensuring the longevity and efficiency of industrial processes.

Wholesale Refractory Materials from supplier in Guinea Bissau

We understand the importance of high-quality refractory materials in various industries, such as steel, cement, glass, and petrochemicals. Therefore, we ensure that our products meet international standards and undergo strict quality control measures.

Our range of refractory materials includes bricks, castables, mortars, insulation materials, and precast shapes. We offer a wide selection of materials, including high-alumina, fireclay, silica, magnesia, and carbon-based products. Whether you need materials for lining furnaces, kilns, boilers, or other high-temperature applications, we have the right solution for you.

In addition to supplying top-notch products, we also provide comprehensive technical support services. Our experienced team can assist you in selecting the most suitable materials for your specific requirements. We can also offer guidance on installation techniques and provide on-site assistance to ensure the successful implementation of your projects.

As a subsidiary of CNBM, we have a strong global network and access to a wide range of resources. This allows us to offer competitive prices and efficient procurement services. Whether you need a single product or a complete package for your project, we can handle your procurement needs with professionalism and reliability.

We value long-term partnerships with our clients and strive to provide excellent customer service. Our local presence in Guinea Bissau enables us to understand the unique challenges of the region and deliver tailored solutions. We are committed to meeting your deadlines and exceeding your expectations.

Contact us today to discuss your refractory materials requirements in Guinea Bissau. Our team is ready to assist you and provide the best solutions for your projects.

Our range of refractory materials includes bricks, castables, mortars, insulation materials, and precast shapes. We offer a wide selection of materials, including high-alumina, fireclay, silica, magnesia, and carbon-based products. Whether you need materials for lining furnaces, kilns, boilers, or other high-temperature applications, we have the right solution for you.

In addition to supplying top-notch products, we also provide comprehensive technical support services. Our experienced team can assist you in selecting the most suitable materials for your specific requirements. We can also offer guidance on installation techniques and provide on-site assistance to ensure the successful implementation of your projects.

As a subsidiary of CNBM, we have a strong global network and access to a wide range of resources. This allows us to offer competitive prices and efficient procurement services. Whether you need a single product or a complete package for your project, we can handle your procurement needs with professionalism and reliability.

We value long-term partnerships with our clients and strive to provide excellent customer service. Our local presence in Guinea Bissau enables us to understand the unique challenges of the region and deliver tailored solutions. We are committed to meeting your deadlines and exceeding your expectations.

Contact us today to discuss your refractory materials requirements in Guinea Bissau. Our team is ready to assist you and provide the best solutions for your projects.

Hot Search

- Monolithic Refractories in Liberia

- Ceramic Fiber Products in British

- Refractory Bricks in Slovenia

- Raw Materials For Refractory in Mauritania

- Raw Materials For Refractory in Peru

- Ceramic Fiber Products in Brunei

- Raw Materials For Refractory in Guinea

- Raw Materials For Refractory in Syria

- Refractory Bricks in Norway

- Raw Materials For Refractory in Moldova