All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

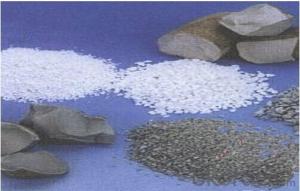

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

How does the chemical composition of raw materials impact the behavior of refractory products?

The chemical composition of raw materials significantly impacts the behavior of refractory products. Certain chemical elements and compounds can alter the refractory's properties such as melting point, thermal conductivity, density, and resistance to thermal shock. For instance, the addition of alumina (Al2O3) can enhance the refractory's resistance to high temperatures, while the presence of silica (SiO2) can improve its ability to withstand thermal shocks. Therefore, understanding the chemical composition of raw materials is crucial in formulating refractory products with desired characteristics and performance.

How does antimony oxide enhance the properties of refractory materials?

Antimony oxide enhances the properties of refractory materials by acting as a flame retardant and increasing their thermal stability. It forms a protective layer on the surface of the material, preventing oxidation and improving resistance to high temperatures. Additionally, antimony oxide acts as a catalyst for the formation of stable compounds, enhancing the mechanical strength and durability of refractory materials.

How do raw materials impact the resistance to thermal spalling of refractory products?

Raw materials have a significant impact on the resistance to thermal spalling of refractory products. The composition and quality of the raw materials used in the manufacturing process directly affect the product's ability to withstand high temperatures without deteriorating. Specifically, raw materials with high refractoriness, thermal stability, and low thermal expansion coefficients enhance the resistance to thermal spalling, reducing the risk of cracks and breakages when exposed to extreme heat.

Can you explain the role of olivine in refractory materials?

Olivine is a mineral that is commonly used in refractory materials due to its high melting point and thermal stability. It acts as a refractory aggregate, providing strength and resistance to high temperatures in various applications. Olivine's ability to withstand thermal shock and chemical erosion makes it an ideal component in refractory materials for industries such as steelmaking, glass manufacturing, and foundries. Additionally, olivine's unique crystal structure allows it to retain its strength and shape even at extreme temperatures, enhancing the overall performance and durability of refractory materials.

Wholesale Raw Materials For Refractory from supplier in Moldova

With our sales, quotation, and technical support services, we ensure that you have a seamless experience in procuring Raw Materials For Refractory in Moldova. As a subsidiary platform of CNBM, a Fortune Global 500 company, we have access to a wide range of high-quality raw materials that are essential for refractory applications.

Our extensive product range includes materials such as alumina, magnesia, silica, and various additives that are crucial for the production of refractory products. Whether you need materials for the construction of furnaces, kilns, or any other high-temperature applications, we have the perfect solutions for you.

In addition to our wide product range, we also bring years of experience in the Moldovan market. We understand the specific requirements and challenges of the local industry, allowing us to provide valuable insights and recommendations for your projects. Our team of experts is always ready to assist you in finding the right raw materials that meet your specifications and budget.

When you choose us as your supplier, you can expect not only high-quality products but also reliable and efficient service. We are dedicated to delivering your orders on time, ensuring that your production processes are not disrupted. Our sales and technical support team is available to address any queries or concerns you may have, providing you with the necessary guidance throughout the procurement process.

Partner with us and let us be your trusted supplier of Raw Materials For Refractory in Moldova. We are committed to meeting your needs and exceeding your expectations with our top-notch products and services. Contact us today and let us assist you in sourcing the perfect raw materials for your refractory applications.

Our extensive product range includes materials such as alumina, magnesia, silica, and various additives that are crucial for the production of refractory products. Whether you need materials for the construction of furnaces, kilns, or any other high-temperature applications, we have the perfect solutions for you.

In addition to our wide product range, we also bring years of experience in the Moldovan market. We understand the specific requirements and challenges of the local industry, allowing us to provide valuable insights and recommendations for your projects. Our team of experts is always ready to assist you in finding the right raw materials that meet your specifications and budget.

When you choose us as your supplier, you can expect not only high-quality products but also reliable and efficient service. We are dedicated to delivering your orders on time, ensuring that your production processes are not disrupted. Our sales and technical support team is available to address any queries or concerns you may have, providing you with the necessary guidance throughout the procurement process.

Partner with us and let us be your trusted supplier of Raw Materials For Refractory in Moldova. We are committed to meeting your needs and exceeding your expectations with our top-notch products and services. Contact us today and let us assist you in sourcing the perfect raw materials for your refractory applications.

Hot Search

- Monolithic Refractories in Cameroon

- Ceramic Fiber Products in Timor Leste

- Refractory Bricks in Turkey

- Raw Materials For Refractory in Romania

- Refractory Bricks in Ukraine

- Monolithic Refractories in Brunei

- Raw Materials For Refractory in Cambodia

- Raw Materials For Refractory in Belize

- Refractory Bricks in Libya

- Monolithic Refractories in Nauru