All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How does the tin coating affect the magnetic properties of electrolytic tinplate coil?

The tin coating on electrolytic tinplate coil acts as a barrier between the steel substrate and the surrounding environment, protecting it from corrosion. However, the tin coating itself is non-magnetic, which means it does not affect the magnetic properties of the tinplate coil. The magnetic properties are primarily determined by the steel substrate, and the presence of the tin coating does not significantly alter these properties.

How is the tin coating adhesion strength measured on electrolytic tinplate coil?

The tin coating adhesion strength on electrolytic tinplate coil is typically measured using a variety of methods, including tape test, scratch test, cross-cut test, and bend test. These tests evaluate the ability of the tin coating to adhere to the substrate by assessing its resistance to peeling, scratching, cutting, or cracking under certain conditions.

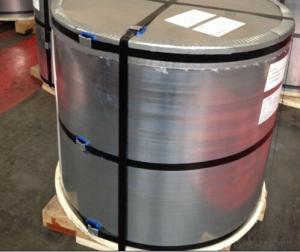

How is electrolytic tinplate coil protected during transportation?

Electrolytic tinplate coils are protected during transportation through various measures such as proper packaging, cushioning, and securing. They are typically wrapped with protective materials like plastic or paper to prevent scratches or damage to the surface. Additionally, the coils may be placed on pallets and secured with straps or bands to ensure stability during transit. These measures help safeguard the tinplate coils from external impacts and maintain their quality until they reach their destination.

What are the common methods for labeling and marking electrolytic tinplate coil?

The common methods for labeling and marking electrolytic tinplate coil include using adhesive labels, embossing, laser engraving, or inkjet printing. These methods help identify the product, provide necessary information, and ensure traceability throughout the supply chain.

Wholesale Electrolytic Tinplate Coil from supplier in Moldova

Whether you are in need of Electrolytic Tinplate Coils for packaging, canning, or any other application, we are here to fulfill your requirements. Our sales team is dedicated to providing personalized assistance, helping you find the right product that meets your specific needs and budget.

When you work with us, you can expect competitive prices, prompt quotations, and efficient delivery services. We understand the importance of timely supply, and our extensive network allows us to ensure that your orders are delivered on time, every time.

Furthermore, our technical support team is available to provide guidance and assistance throughout your project. Whether you have questions about product specifications, application techniques, or any other technical aspect, our experts are here to help.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the backing of a strong parent company that is renowned for its reliability and expertise. This allows us to provide a complete procurement solution, ensuring that you have access to high-quality Electrolytic Tinplate Coils at competitive prices.

With our years of experience in the Moldovan market, we have built strong relationships with local suppliers and manufacturers. This enables us to offer valuable insights and expertise, helping you navigate the local market and make informed decisions for your projects.

In summary, when you choose us as your supplier of Electrolytic Tinplate Coils in Moldova, you can expect comprehensive services, competitive prices, efficient delivery, and expert technical support. We strive to be your trusted partner, meeting all your Electrolytic Tinplate Coil needs and exceeding your expectations. Contact us today to discuss your requirements and let us provide you with a tailored solution.

When you work with us, you can expect competitive prices, prompt quotations, and efficient delivery services. We understand the importance of timely supply, and our extensive network allows us to ensure that your orders are delivered on time, every time.

Furthermore, our technical support team is available to provide guidance and assistance throughout your project. Whether you have questions about product specifications, application techniques, or any other technical aspect, our experts are here to help.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the backing of a strong parent company that is renowned for its reliability and expertise. This allows us to provide a complete procurement solution, ensuring that you have access to high-quality Electrolytic Tinplate Coils at competitive prices.

With our years of experience in the Moldovan market, we have built strong relationships with local suppliers and manufacturers. This enables us to offer valuable insights and expertise, helping you navigate the local market and make informed decisions for your projects.

In summary, when you choose us as your supplier of Electrolytic Tinplate Coils in Moldova, you can expect comprehensive services, competitive prices, efficient delivery, and expert technical support. We strive to be your trusted partner, meeting all your Electrolytic Tinplate Coil needs and exceeding your expectations. Contact us today to discuss your requirements and let us provide you with a tailored solution.