All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

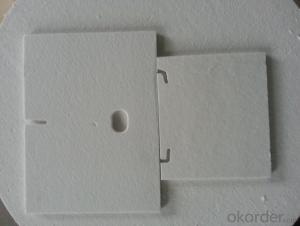

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Monolithic RefractoriesView More

Ceramic Fiber ProductsView More

Refractory BricksView More

Raw Materials For RefractoryView More

Q & A

How are refractory materials cured?

Refractory materials are typically cured through a process known as heat treatment, where the material is exposed to high temperatures for a specific duration to enhance its physical and chemical properties.

How do refractory materials resist the attack of corrosive substances in kilns?

Refractory materials resist the attack of corrosive substances in kilns through their ability to withstand high temperatures and chemical reactions. These materials are designed to have low porosity, high chemical stability, and good thermal shock resistance. This makes them resistant to the corrosive effects of acids, alkalis, and other corrosive substances present in the kiln environment. Additionally, refractory materials often form a protective layer or coating on their surface, which acts as a barrier against further corrosion.

What are the different types of refractory fibers for corrosion resistance?

Some different types of refractory fibers for corrosion resistance include alumina fibers, silica fibers, zirconia fibers, and boron nitride fibers.

What are the challenges faced by refractory materials in the chemical industry?

One of the main challenges faced by refractory materials in the chemical industry is the harsh and corrosive environments they are exposed to. Chemical processes often involve high temperatures, aggressive chemicals, and rapid temperature changes, which can cause significant wear and degradation of refractory materials. Additionally, the selection of suitable refractory materials for various chemical processes can be complex, as different materials may be required to withstand specific chemical reactions and conditions. The need for continuous monitoring and maintenance of refractory linings further adds to the challenges faced by these materials in the chemical industry.

Wholesale Refractory Materials from supplier in Moldova

Whether you are in need of refractory bricks, castables, mortars, or any other refractory materials, we have you covered. Our team of experts is dedicated to delivering high-quality products that meet international standards, ensuring the durability and performance of your projects.

In addition to our wide range of products, we also offer sales and quotations services to assist you in finding the best solution for your specific needs. Our knowledgeable sales team is always ready to provide you with detailed information and competitive pricing, ensuring that you make informed decisions.

Furthermore, our technical support services are available to help you with any challenges or questions you may have during the application of our refractory materials. Our experienced technicians can offer guidance and suggestions to ensure the successful implementation of your projects.

As a subsidiary of CNBM, we benefit from the resources and expertise of a Fortune Global 500 company. This allows us to provide efficient and convenient one-stop procurement services, saving you time and effort in sourcing the right refractory materials for your projects.

With our years of experience in the Moldova market, we understand the unique requirements and challenges that you may face. We have built strong relationships with local suppliers and have a deep understanding of the industry in Moldova. This knowledge and expertise enable us to offer tailored solutions and support that meet your specific needs.

Choose us as your trusted supplier of refractory materials in Moldova, and you can rely on our high-quality products, competitive pricing, and comprehensive support services. Contact us today to discuss your requirements and let us assist you in achieving the success of your projects.

In addition to our wide range of products, we also offer sales and quotations services to assist you in finding the best solution for your specific needs. Our knowledgeable sales team is always ready to provide you with detailed information and competitive pricing, ensuring that you make informed decisions.

Furthermore, our technical support services are available to help you with any challenges or questions you may have during the application of our refractory materials. Our experienced technicians can offer guidance and suggestions to ensure the successful implementation of your projects.

As a subsidiary of CNBM, we benefit from the resources and expertise of a Fortune Global 500 company. This allows us to provide efficient and convenient one-stop procurement services, saving you time and effort in sourcing the right refractory materials for your projects.

With our years of experience in the Moldova market, we understand the unique requirements and challenges that you may face. We have built strong relationships with local suppliers and have a deep understanding of the industry in Moldova. This knowledge and expertise enable us to offer tailored solutions and support that meet your specific needs.

Choose us as your trusted supplier of refractory materials in Moldova, and you can rely on our high-quality products, competitive pricing, and comprehensive support services. Contact us today to discuss your requirements and let us assist you in achieving the success of your projects.

Hot Search

- Monolithic Refractories in Finland

- Ceramic Fiber Products in Turkey

- Refractory Bricks in Mauritania

- Raw Materials For Refractory in Belgium

- Monolithic Refractories in Brazil

- Refractory Bricks in Qatar

- Ceramic Fiber Products in Malta

- Monolithic Refractories in Tunisia

- Refractory Bricks in Barbados

- Ceramic Fiber Products in Moldova