All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What is the impact of coil defects on the reliability and safety of automotive braking systems and components?

Coil defects in automotive braking systems and components can have a significant impact on their reliability and safety. These defects can lead to various issues, such as reduced braking performance, uneven brake force distribution, and even complete brake failure. When a coil is defective, it may not generate the necessary magnetic field strength to properly engage the brakes or control the brake pressure. This can result in longer stopping distances, decreased responsiveness, and compromised overall braking effectiveness. Moreover, coil defects can cause the brakes to engage unevenly, leading to a loss of stability and control during braking. In extreme cases, faulty coils can lead to catastrophic brake failures, putting the safety of the vehicle and its occupants at risk. Therefore, it is crucial to ensure the quality and integrity of coils in automotive braking systems to maintain reliable and safe braking performance.

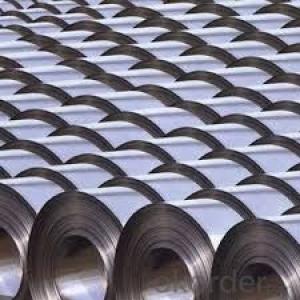

How are steel coils prepared for the production of metal construction materials?

Steel coils are prepared for the production of metal construction materials by undergoing a series of steps. First, the coils are uncoiled and straightened to remove any bends or twists. Then, they are cleaned to remove any dirt or contaminants. Next, the coils are cut into sheets of the desired size using specialized machinery. These sheets may then go through additional processes such as galvanizing, where a protective layer of zinc is applied, or cold rolling, which can improve the surface finish. Finally, the prepared coils are ready to be transformed into various metal construction materials such as beams, pipes, or panels.

What are the common methods of steel coil slitting?

The common methods of steel coil slitting include rotary shear slitting, loop slitting, and single knife slitting.

Wholesale Steel Coils from supplier in Moldova

We understand the importance of delivering high-quality products to meet your specific requirements. Our Steel Coils are sourced from reliable manufacturers, ensuring consistent quality and performance. We offer a wide range of Steel Coils, including hot-rolled coils, cold-rolled coils, galvanized coils, and stainless steel coils, among others.

Our team of experienced professionals is dedicated to providing exceptional customer service. We can assist you in selecting the most suitable Steel Coils for your applications and offer competitive pricing options. Our technical support team is available to address any queries or concerns you may have, ensuring a smooth and successful procurement process.

We have established strong relationships with shipping and logistics companies, allowing us to efficiently handle the transportation and delivery of Steel Coils to Moldova. Our extensive network of suppliers and partners enables us to fulfill your orders promptly and reliably.

At CNBM, we prioritize customer satisfaction and strive to exceed your expectations. Whether you require Steel Coils for construction, manufacturing, or any other industry, we are here to provide you with the best solutions. Contact us today to discuss your Steel Coils requirements in Moldova and let us be your trusted partner in procurement.

Our team of experienced professionals is dedicated to providing exceptional customer service. We can assist you in selecting the most suitable Steel Coils for your applications and offer competitive pricing options. Our technical support team is available to address any queries or concerns you may have, ensuring a smooth and successful procurement process.

We have established strong relationships with shipping and logistics companies, allowing us to efficiently handle the transportation and delivery of Steel Coils to Moldova. Our extensive network of suppliers and partners enables us to fulfill your orders promptly and reliably.

At CNBM, we prioritize customer satisfaction and strive to exceed your expectations. Whether you require Steel Coils for construction, manufacturing, or any other industry, we are here to provide you with the best solutions. Contact us today to discuss your Steel Coils requirements in Moldova and let us be your trusted partner in procurement.