All Categories

- - Steel Wire Rod

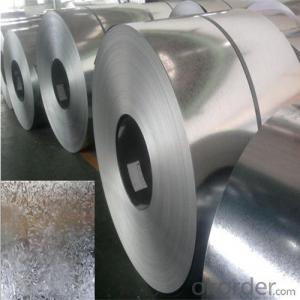

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

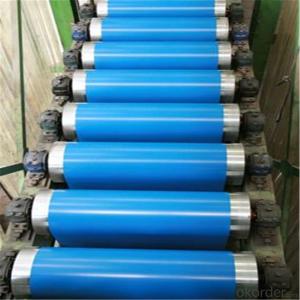

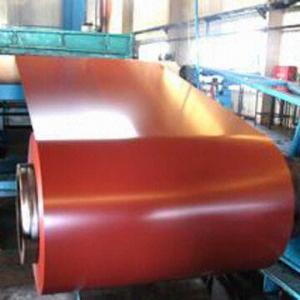

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How is coil cleanliness maintained during the fabrication of medical devices and instruments?

Coil cleanliness is maintained during the fabrication of medical devices and instruments through several measures. Firstly, the manufacturing environment is kept clean and controlled, adhering to strict cleanliness protocols and regulations. This includes maintaining cleanrooms, controlling air quality, and implementing proper handling and storage procedures.

Secondly, during the fabrication process, coils are often cleaned using various techniques such as ultrasonic or chemical cleaning. These methods help to remove any contaminants, debris, or residues that may have accumulated during the manufacturing process.

Furthermore, regular inspection and quality control checks are conducted to ensure that the coils meet the required cleanliness standards. This involves visual inspection, testing, and validation procedures to confirm that the coils are free from any impurities or foreign particles.

Overall, a combination of a clean manufacturing environment, proper cleaning techniques, and rigorous quality control measures is employed to maintain coil cleanliness during the fabrication of medical devices and instruments.

How are steel coils tested for their resistance to impact and wear in the mining and heavy equipment sector?

Steel coils in the mining and heavy equipment sector are commonly tested for their resistance to impact and wear through rigorous methods such as drop weight testing, hardness testing, and abrasion testing. These tests involve subjecting the coils to controlled impacts, measuring their hardness, and assessing their ability to withstand abrasion, respectively. These evaluations ensure that the steel coils meet the required standards and can withstand the demanding conditions in the mining and heavy equipment industry.

What is the role of tension control in precision slitting for roll-forming applications?

The role of tension control in precision slitting for roll-forming applications is to ensure that the material being slit is held at a consistent tension throughout the process. This is important because maintaining proper tension prevents wrinkling, stretching, or other defects in the material. It ensures that the slitting process is accurate and precise, resulting in high-quality products that meet the desired specifications.

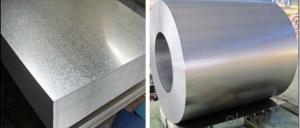

What are the different grades of steel coils?

The different grades of steel coils vary in terms of their composition and properties. Some common grades include low carbon steel coils (e.g., ASTM A36), medium carbon steel coils (e.g., ASTM A572), high-strength low alloy (HSLA) steel coils (e.g., ASTM A656), and stainless steel coils (e.g., grade 304 or 316). Each grade is designed for specific applications and has unique characteristics such as strength, corrosion resistance, and weldability.

Wholesale Steel Coils from supplier in Georgia

With our extensive range of Steel Coils products and exceptional services, we are confident in our ability to meet your Steel Coils procurement needs in Georgia. As a leading supplier in the region, we have built a strong reputation for quality, reliability, and customer service.

Our affiliation with CNBM, a Fortune Global 500 company, gives us access to global resources and expertise, ensuring that we can provide you with the best products and support. We understand the unique demands of the Georgia market and have the knowledge and experience to cater to them effectively.

When you choose us as your trusted Steel Coils supplier, you can expect a comprehensive product portfolio tailored to meet diverse requirements. Our team is dedicated to delivering exceptional products and assisting you every step of the way, from quotation to technical support. We aim to ensure customer satisfaction and provide invaluable insights and expertise for your projects.

Experience the convenience of our one-stop procurement services, backed by the global reputation and resources of CNBM. We are proud to be your go-to platform for all your Steel Coils needs in Georgia. Contact us today and let us be your trusted partner in steel procurement.

Our affiliation with CNBM, a Fortune Global 500 company, gives us access to global resources and expertise, ensuring that we can provide you with the best products and support. We understand the unique demands of the Georgia market and have the knowledge and experience to cater to them effectively.

When you choose us as your trusted Steel Coils supplier, you can expect a comprehensive product portfolio tailored to meet diverse requirements. Our team is dedicated to delivering exceptional products and assisting you every step of the way, from quotation to technical support. We aim to ensure customer satisfaction and provide invaluable insights and expertise for your projects.

Experience the convenience of our one-stop procurement services, backed by the global reputation and resources of CNBM. We are proud to be your go-to platform for all your Steel Coils needs in Georgia. Contact us today and let us be your trusted partner in steel procurement.