All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

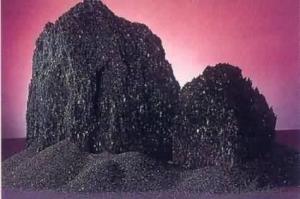

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

How do refractories perform in the presence of alkali vapor in combustion systems?

Refractories generally perform well in the presence of alkali vapor in combustion systems due to their high resistance to alkali attack. They are able to withstand the corrosive effects of alkali vapors, which can lead to degradation and erosion of other materials. Refractories are specifically designed to have low porosity and high chemical stability, allowing them to maintain their structural integrity and functionality even in harsh environments.

How does cordierite contribute to the properties of refractory materials?

Cordierite, a magnesium aluminum silicate mineral, has numerous contributions to the properties of refractory materials. Its low thermal expansion coefficient allows for excellent thermal shock resistance, making it highly effective in high-temperature applications. Additionally, cordierite's high melting point ensures stability and durability even under extreme heat conditions. Its low electrical conductivity also makes it suitable for insulating purposes. Overall, cordierite significantly enhances the thermal and mechanical properties of refractory materials, making them ideal for use in various industrial applications.

What are the raw materials used in the production of silica refractories?

The raw materials used in the production of silica refractories are primarily silica sand, along with various additives such as clay, alumina, and fluxes.

Can you explain the role of periclase in refractories?

Periclase is a crucial component in refractories due to its high melting point and excellent thermal stability. It acts as a refractory aggregate and helps enhance the refractory's resistance to high temperatures, thermal shock, and chemical corrosion. Additionally, periclase contributes to the refractory's mechanical strength and overall durability. Its presence in refractories ensures that they can withstand harsh conditions in industries such as steelmaking, glass manufacturing, and cement production.

Wholesale Raw Materials For Refractory from supplier in Belize

Whether you are in need of high-quality materials for furnace linings, kiln furniture, or other refractory applications, we have you covered. Our vast selection includes materials such as high alumina, magnesia, silica, zirconia, and more.

When you choose us as your supplier, you can expect exceptional customer service. Our dedicated team is committed to providing prompt responses to your inquiries, offering competitive pricing, and delivering products in a timely manner. We understand the importance of reliable and efficient supply chain management, and we strive to exceed your expectations in this regard.

Additionally, our technical support services are designed to assist you throughout the entire process. Whether you need guidance on material selection, installation techniques, or troubleshooting, our experienced engineers are ready to lend their expertise. We believe in building long-term partnerships with our customers, and we are committed to helping you achieve success with your refractory projects.

As a subsidiary of CNBM, a leading company in the global building materials industry, we have access to a vast network of resources. This enables us to source the highest quality raw materials from trusted suppliers around the world. Our strong procurement capabilities ensure that you receive reliable and consistent products, meeting the highest industry standards.

In conclusion, if you are in Belize and require raw materials for refractory products, we are your trusted partner. With our wide range of products, exceptional customer service, and technical support, we are confident that we can meet your specific requirements. Contact us today to discuss your needs and let us assist you in achieving your refractory goals.

When you choose us as your supplier, you can expect exceptional customer service. Our dedicated team is committed to providing prompt responses to your inquiries, offering competitive pricing, and delivering products in a timely manner. We understand the importance of reliable and efficient supply chain management, and we strive to exceed your expectations in this regard.

Additionally, our technical support services are designed to assist you throughout the entire process. Whether you need guidance on material selection, installation techniques, or troubleshooting, our experienced engineers are ready to lend their expertise. We believe in building long-term partnerships with our customers, and we are committed to helping you achieve success with your refractory projects.

As a subsidiary of CNBM, a leading company in the global building materials industry, we have access to a vast network of resources. This enables us to source the highest quality raw materials from trusted suppliers around the world. Our strong procurement capabilities ensure that you receive reliable and consistent products, meeting the highest industry standards.

In conclusion, if you are in Belize and require raw materials for refractory products, we are your trusted partner. With our wide range of products, exceptional customer service, and technical support, we are confident that we can meet your specific requirements. Contact us today to discuss your needs and let us assist you in achieving your refractory goals.

Hot Search

- Monolithic Refractories in Lebanon

- Ceramic Fiber Products in Germany

- Refractory Bricks in Botswana

- Raw Materials For Refractory in Denmark

- Monolithic Refractories in Thailand

- Ceramic Fiber Products in Belarus

- Monolithic Refractories in Philippines

- Monolithic Refractories in South Africa

- Raw Materials For Refractory in Tonga

- Raw Materials For Refractory in Colombia