All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

Can monolithic refractories be used for lining petrochemical pyrolysis furnaces?

Yes, monolithic refractories can be used for lining petrochemical pyrolysis furnaces. Monolithic refractories offer excellent thermal insulation and resistance to high temperatures, making them suitable for the harsh conditions inside pyrolysis furnaces. Additionally, their ability to be applied as a single, cohesive layer makes installation easier and more efficient compared to traditional brick linings.

Can monolithic refractories be used in contact with toxic materials?

No, monolithic refractories should not be used in contact with toxic materials as they may not provide sufficient protection against chemical reactions or the release of harmful substances.

What is the recommended thickness for monolithic refractory linings?

The recommended thickness for monolithic refractory linings can vary depending on the specific application and requirements. However, in general, a thickness of at least 2 inches (5 cm) is often recommended to ensure proper insulation and protection against thermal stresses.

Are monolithic refractories suitable for use in chimneys and stacks?

Yes, monolithic refractories are suitable for use in chimneys and stacks. Monolithic refractories are engineered to withstand high temperatures, chemical corrosion, and thermal shock, making them ideal for lining chimneys and stacks where extreme conditions are present. Their ability to be formed and installed in various shapes and sizes allows for efficient and durable lining solutions in these structures.

What are the potential health hazards associated with monolithic refractories?

The potential health hazards associated with monolithic refractories include exposure to dust particles, chemical fumes, and high temperatures. Inhaling the dust particles released during installation or maintenance of monolithic refractories can lead to respiratory issues such as bronchitis or silicosis. The chemical fumes emitted during the curing process or when exposed to high temperatures can cause eye and skin irritation, as well as potential long-term health effects if proper protective measures are not taken.

Wholesale Monolithic Refractories from supplier in Nauru

Our team of experts is dedicated to providing the highest quality Monolithic Refractories products to meet the specific needs of your projects in Nauru. We understand the unique challenges and requirements of working in the island nation and are well-prepared to offer tailored solutions.

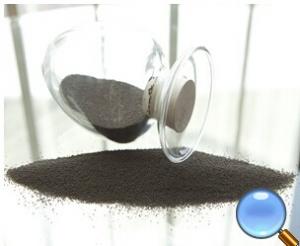

Our range of Monolithic Refractories products includes a wide variety of materials such as castables, ramming mixes, gunning mixes, and plastic refractories. These products are known for their excellent thermal stability, high strength, and resistance to corrosion, making them ideal for various industrial applications.

In addition to supplying top-quality products, we also offer professional services to support your procurement process. Our sales team is knowledgeable and experienced, ready to assist you in choosing the right products for your specific needs. We provide detailed quotations that are transparent and competitive, ensuring that you receive the best value for your investment.

Furthermore, we offer technical support to help you navigate any challenges that may arise during your projects. Our team of experts is available to provide guidance and advice on installation techniques, product selection, and troubleshooting. We are committed to ensuring the success of your projects and will go the extra mile to deliver exceptional service.

As an affiliate of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This affiliation further strengthens our ability to provide top-notch procurement services tailored specifically for the Nauru region.

With our extensive market experience in Nauru, we have developed valuable insights and expertise that can enhance your projects. We understand the local regulations, climate conditions, and industry trends, allowing us to offer informed recommendations and solutions.

In summary, if you are looking for a trusted supplier of Monolithic Refractories in Nauru, we are your one-stop solution. Contact us today to discuss your requirements and discover how we can support your projects with our high-quality products and professional services.

Our range of Monolithic Refractories products includes a wide variety of materials such as castables, ramming mixes, gunning mixes, and plastic refractories. These products are known for their excellent thermal stability, high strength, and resistance to corrosion, making them ideal for various industrial applications.

In addition to supplying top-quality products, we also offer professional services to support your procurement process. Our sales team is knowledgeable and experienced, ready to assist you in choosing the right products for your specific needs. We provide detailed quotations that are transparent and competitive, ensuring that you receive the best value for your investment.

Furthermore, we offer technical support to help you navigate any challenges that may arise during your projects. Our team of experts is available to provide guidance and advice on installation techniques, product selection, and troubleshooting. We are committed to ensuring the success of your projects and will go the extra mile to deliver exceptional service.

As an affiliate of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This affiliation further strengthens our ability to provide top-notch procurement services tailored specifically for the Nauru region.

With our extensive market experience in Nauru, we have developed valuable insights and expertise that can enhance your projects. We understand the local regulations, climate conditions, and industry trends, allowing us to offer informed recommendations and solutions.

In summary, if you are looking for a trusted supplier of Monolithic Refractories in Nauru, we are your one-stop solution. Contact us today to discuss your requirements and discover how we can support your projects with our high-quality products and professional services.

Hot Search

- Monolithic Refractories in Slovenia

- Ceramic Fiber Products in Montenegro

- Refractory Bricks in Nicaragua

- Raw Materials For Refractory in Albania

- Refractory Bricks in Denmark

- Refractory Bricks in Estonia

- Monolithic Refractories in Poland

- Refractory Bricks in Angola

- Refractory Bricks in United Arab Emirates

- Monolithic Refractories in Latvia